Overview

Essential details

Type:

Flexographic Printer

Applicable Industries:

Advertising Company, printing factory, packaging industry

Condition:

New

Plate Type:

Letterpress

Place of Origin:

Zhejiang, China

Brand Name:

lisheng

Usage:

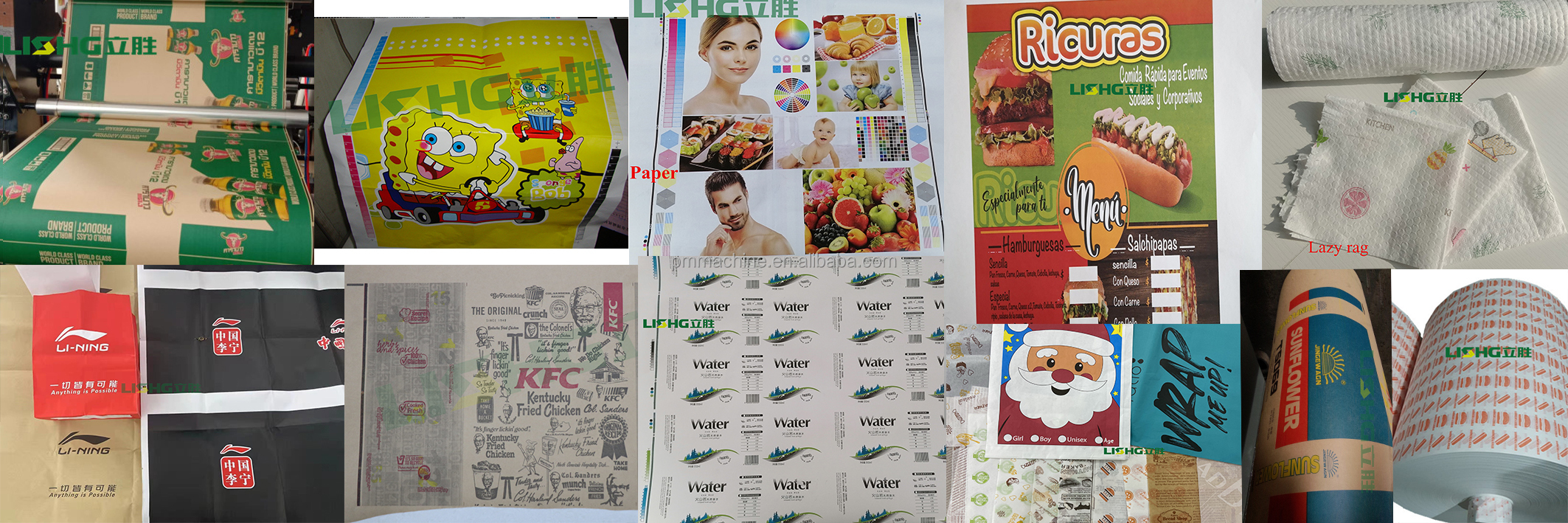

Paper Printer, Plastic Bag, Non Woven Bag, Paper Bag, plastic film

Automatic Grade:

Automatic

Color & Page:

Multicolor

Voltage:

380v

Dimensions(L*W*H):

7200*2320*4820mm

Weight:

12600 KG

Print Dimension:

1200mm

Print Speed:

180m/min

Warranty:

1 Year

Key Selling Points:

High Productivity

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Bearing, Motor, Pump, Gear, PLC

Structure:

CI

Product Name:

paper bag printing machine

Model:

flexography printer

Function:

paper bag printing machine

Printing material:

paper bag thermal paper hamburger paper oiled paper

Application:

thermal paper printing machine

Printing color:

4/ 6/ 8 Colors

Anilox roller:

Ceramic Anilox Roller

Ink:

water based ink and solvent ink

Speed:

180m/min

After-sales service:

Service Machinery Overseas

Supply Ability

Supply Ability

20 Set/Sets per Month or more

Packaging & delivery

Packaging Details

Film package, printing unit with wodden box

Port

Ningbo

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 90 To be negotiated

Video Description

Product Description

6 colors High Speed Central Drum Plastic woven bag Flexo Printer flexographic printing machine

This central impression (central drum)flexographic printing machine is suitable for printing such packing materials as polyethylene, polyethylene plastic bag, leather, glass paper and roll paper etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

Production Process

Sample pictures

Details Images

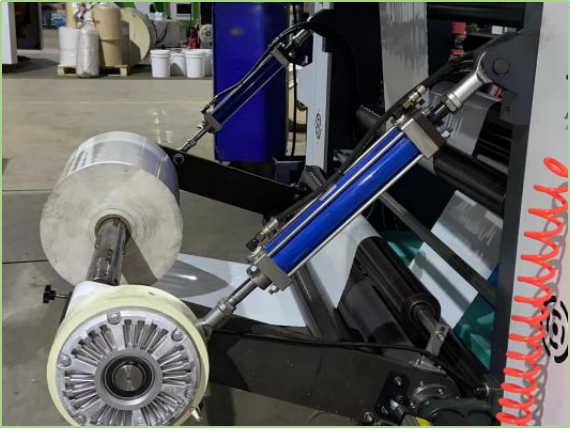

Feeding Material Part

1.Automatic stop machine when break the material.

2.Single unwinding system, equipped with air shaft , EPC and automatic tension control system with magnetic brake.

3.Roller core diameter: 76mm

4.Discharge maximum diameter: 1000mm

5.Pneumatic load and unload material.

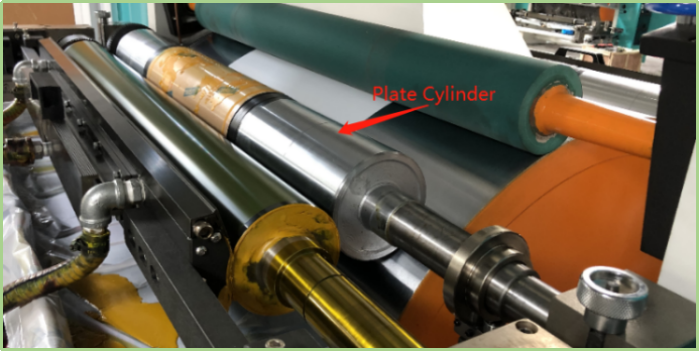

Printing Sections

1.Printing consists of: central drum, plate roller, ceramic anilox roller, single doctor blade and chamber doctor blade. 2.Plate roller circumference: 300-800mm. 3.Print material: resin plate or rubber plate. 4.Transmission: central drum with big gear drive the printing station.