Overview

Essential details

Type:

Multi-Function Packaging Machine

Production Capacity:

20bag/min, 40bag/min, 25bag/min, 50bag/min, 30bag/min

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory, Restaurant, Food Shop, Construction works , Energy & Mining, Food & Beverage Shops

Weight (KG):

600

Showroom Location:

None

Condition:

New

Function:

FILLING, Wrapping, Labeling, packing, Filling, Wrapping, Labeling, Sealing, printing

Application:

Food, Medical, Chemical

Packaging Type:

Cartons, Stand-up Pouch, Bags, Film, Stand-up Pouch, Bags, Pouch

Packaging Material:

Plastic, Wood

Automatic Grade:

Automatic

Driven Type:

Electric, Electrical and pneumatic

Voltage:

220V

Place of Origin:

Guangdong, China

Brand Name:

JINTIAN PACK

Dimension(L*W*H):

(L)1080mm*(W)1300mm*(H)2100mm

Warranty:

2 years

Key Selling Points:

High-accuracy

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor, Pressure vessel, Pump, PLC, Gear, Engine, Gearbox

Machine material:

stainless steel 304

Packing material:

Opp/Cpp CPP/PE MST/PE PET/PI

Machine Language:

English, Spanish, French, Arabic

Air consumption:

0.6Mpa300L/min

Product name:

Multi-Function Packaging Machine

Bag type:

Back Sealing

Main Function:

Weighing Forming Filling Sealing

Marketing Type:

New Product 2021

Supply Ability

Supply Ability

100 Set/Sets per Month

Packaging & delivery

Packaging Details

A.Standard Export Plywood Packaging

B.According the customer to request to packaging

C.Other packaging detail please contacts seller to confirm Packaging Details

Port

guangzhou/shenzhen

Picture Example:

Lead time:

Quantity(sets) 1 - 1 2 - 3 4 - 4 >4 Lead time (days) 15 25 35 To be negotiated

Video Description

Product Description

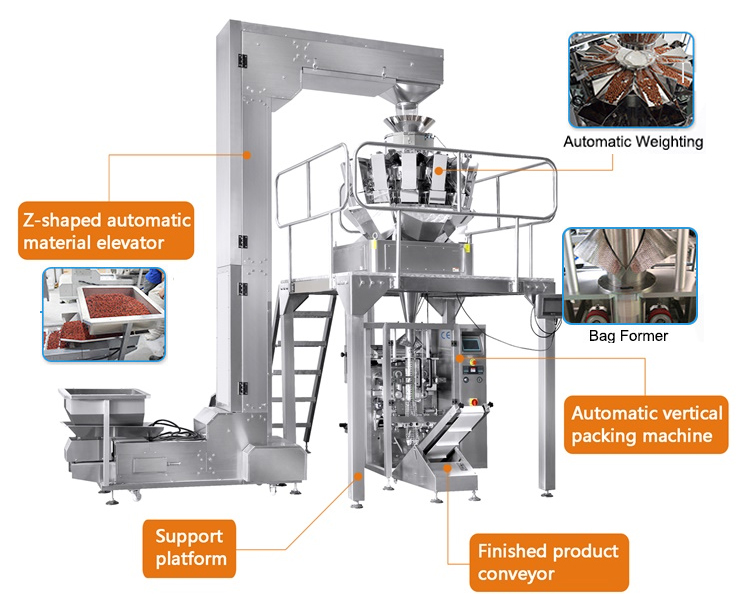

Factory Selling High Precision Automatic Weighing Pouch Small Snack food Packing Machine

Technical characteristics:

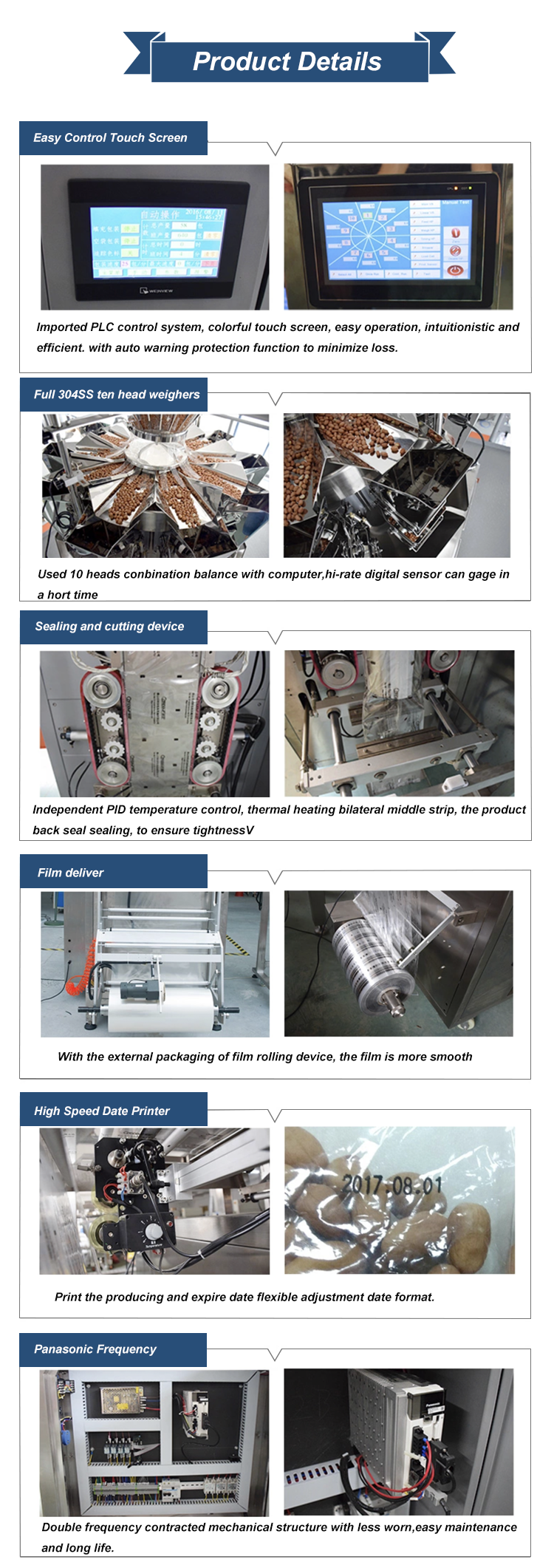

1. PLC control with stable reliable biaxial high accuracy output and color touch screen, bag-making, measuring, filling, printing,cutting , finished in one operation.

2. Separate circuit boxes for pneumatic control and power control. Noise is low, and the circuit is more stable.

3. Film-pulling with servo motor double belt: less pulling resistance, bag is formed in good shape with better appearance, belt is resistant to be worn-out.

4. External film releasing mechanism: simpler and easier installation of packing film.

5. Adjustment of bag deviation just needed to be controlled by the touch screen. Operation is very simple .

6. Close down type mechanism , defending powder into inside of machine.

Application

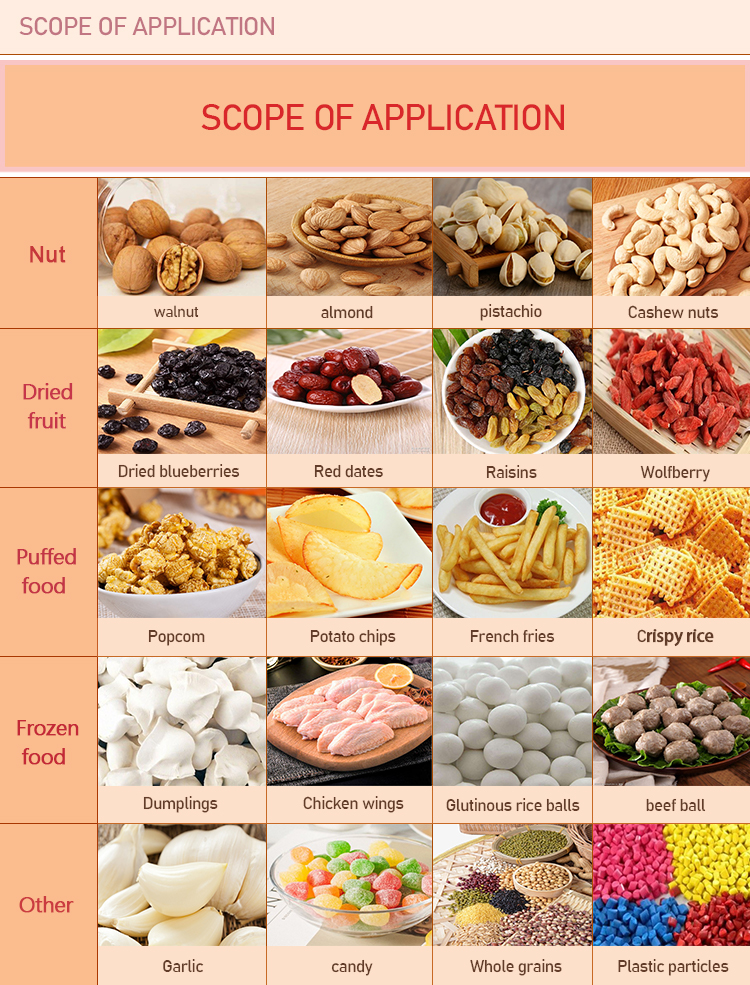

Suitable for packaging many different kinds of products; such as puffy food, shrimp roll, peanut, popcorn, cornmeal, dried fruit, seed, small hardware,dumplings, vegetable, fruits and sugar etc.which shape is roll, slice and granule.

Vertial packing machine

Automatic filling and sealing together .

Master control circuit adopts imported PLC microcomputer with man-machine interface andfrequency control,making setting paramaters (to adjust bag length and width, packing speed,cutting position) convenient and quick and operation intuitive. Full implement the humanizesautomatic operation

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .