Overview

Essential details

Type:

Multi-Function Packaging Machine

Applicable Industries:

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Home Use, Retail, Food Shop, Food & Beverage Shops

Weight (KG):

500

Showroom Location:

United Kingdom, United States, Saudi Arabia, Mexico, Thailand, Algeria, Romania, Bangladesh, Kyrgyzstan

Condition:

New

Function:

FILLING, Wrapping, Laminating, Sealing

Application:

Food, Medical, Packing Products

Packaging Type:

Bags, Film, Pouch, Stand-up Pouch

Packaging Material:

Plastic

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

220V

Place of Origin:

Zhejiang, China

Brand Name:

Zon Pack

Dimension(L*W*H):

1550(L)*1150(W)*1750(H)

Warranty:

1 Year

Key Selling Points:

Easy to Operate

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other

Production Capacity:

40bag/min, 50bag/min, 30bag/min

Type of Bag Making:

Pillow bag, gusset bag, punching bag , connecting bag

Material:

304SS

Packing speed:

15-70bags/min

Max Film Width:

420mm

Product name:

Snack Packaging Machine

After-sales Service Provided:

Field installation, commissioning and training

Feature:

High Digital System

Technical Feature:

Easy to Operate

Power Parameter:

220V 50/60Hz 3KW

Supply Ability

Supply Ability

199 Set/Sets per Month packaging machine

Packaging & delivery

Packaging Details

Wooden case;banana chips packing machine;potato chips packaging machine

Port

Shanghai/Ningbo Port

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 25 To be negotiated

Products Description

Product Application

It is suitable for packing grain, stick, slice, globose, irregular shape products such as puffy food, snacks, candy, chocolate, nuts, pistachio, pasta, coffee bean, sugar, chips, cereals, pet food, fruits, roasted seeds, frozen food, small hardware, etc.

Main Features

1. Adopting PLC from Japan or Germany to make machine run stable. Touch screen from Tai Wan to make operation easy.

2. Sophisticated design on electronic and pneumatic control system makes the machine with high level of precision, reliability and stability.

3. Single-belt pulling with servo of high precise positioning makes film transporting system stable, servo motor from Siemens or Panasonic.

4. Perfect alarm system to make problem solved quickly.

5. Adopting intellectual temperature controller,the temperature is controlled to ensure neat sealing.

6. Machine can make pillow bag and standing bag (gusseted bag) according to customer's requirements. Machine also can make bag with punching hole & linked bag from 5-12 bags and so on.

7. Working with weighing or filling machines such as multihead weigher, volumetric cup filler, auger filler or feeding conveyor, process of weighing, bag making, filling, date printing, charging (exhausting), sealing, counting and delivering finished product can be completed automatically.

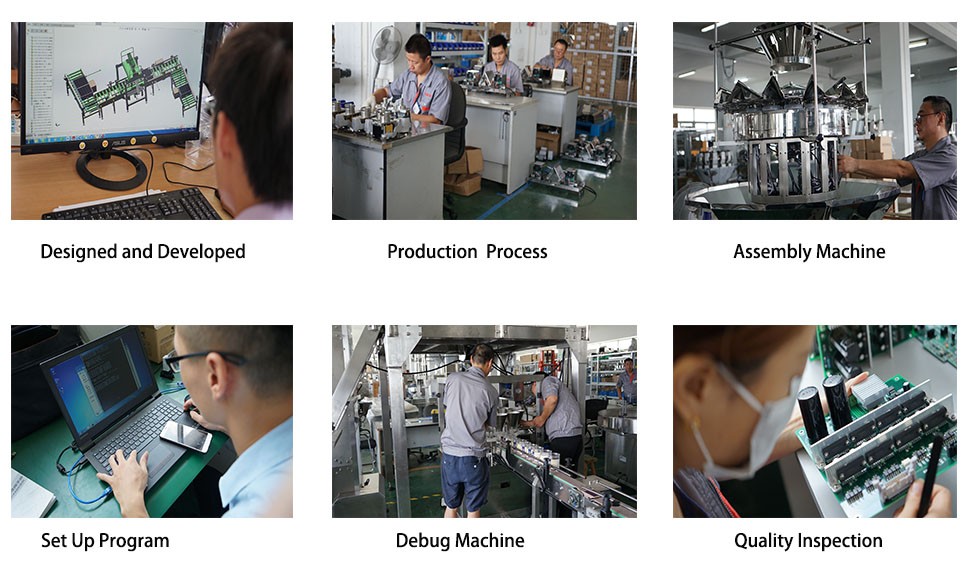

Detailed Images

1.Bucket Conveyor

Machine frame: 304SS or Mildsteel frame

304ss Chain

Conveyor Height : 2.5-3.8m

Conveyor Volume : 2.5-5CBM/Hour

Bucket hopper volume :0.8L,2L,4L,10L

Bucket hopper material: 304SS, Food grade plastics

Bucket can be removed, and it is convenient to clean

2.Multihead weigher

We usually use multihead weigher to measure the target weight.

Machine type:4 head, 10head ,14 head,20 head

Machine accuracy :± 0.1g

Material weight range: 10-5kg

3.Working platform

304SS frame , support the multihead weigher.

The Standard size: 1.8m(L)*1.8m(W)*1.8m(H)

Can make according your requirement

4. Packing machine

304SS frame,

Bag size:

ZH-V420 Packing machine: (W) 60-200 (L)60-300

ZH-V520 Packing machine:(W) 90-250 (L)80-350

ZH-V620 Packing machine:(W) 100-300 (L)100-400

ZH-V720 Packing machine:(W) 120-350 (L)100-450

Bag making :

Pillow bag, standing bag (gusseted), punch, linked bag

5.Finished- conveyor

PP material, motor control,

Translae bag more conveniently which was packaged.

6.Rotary collected table

304SS frame

Collecte the bag in the table, and suitable height for workers pick bags in cartons.

Related Products

High Accuracy metal Detector

High Speed Rotary Packing Machine

High Accuracy Multihead Weigher

High Speed Rotary Packing System

High Speed Vertical Packing Machine

High Speed Bottle Filling Machine

Case & Customer

Our Company

Our Team