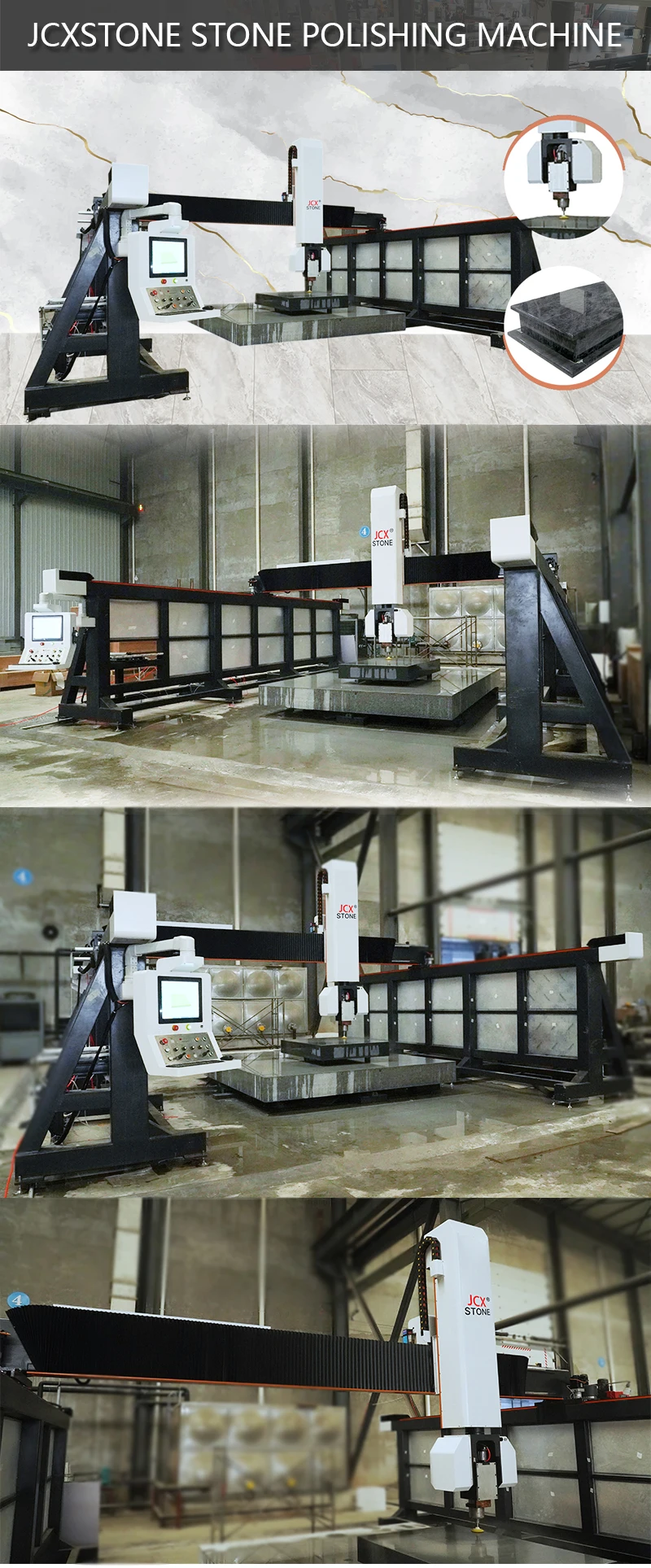

Processing size: X-axis stroke | lateral dimension 4000mm |

Processing size: Y-axis stroke | longitudinal dimension 6000mm |

Motor power | 15KW |

Machine tool body | Seamless welding, aging treatment, five-sided milling machine processing |

Surface treatment | High temperature spray to prevent paint loss |

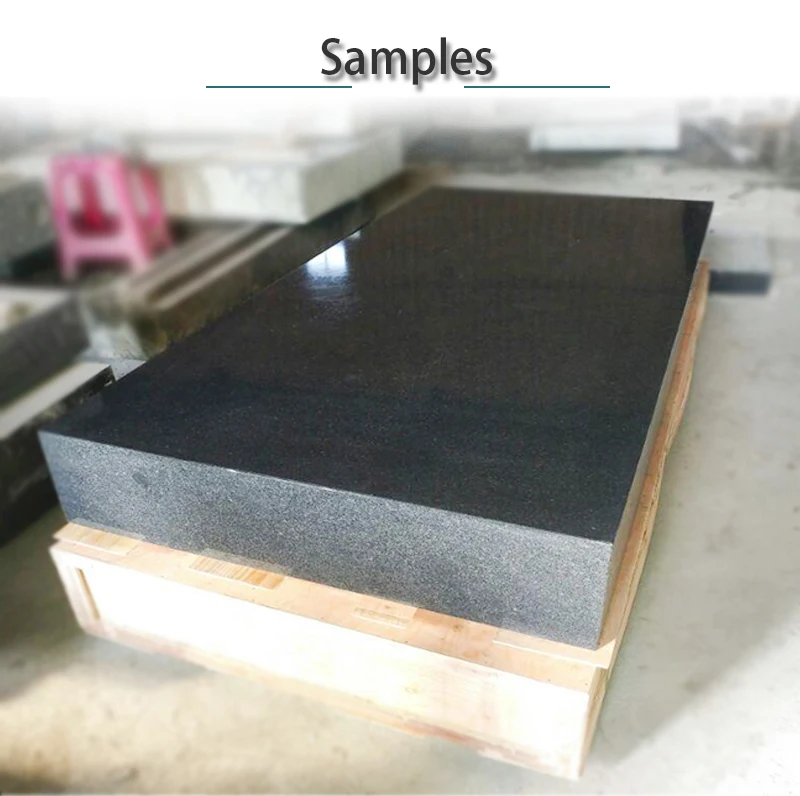

Machining thickness | 500mm within |

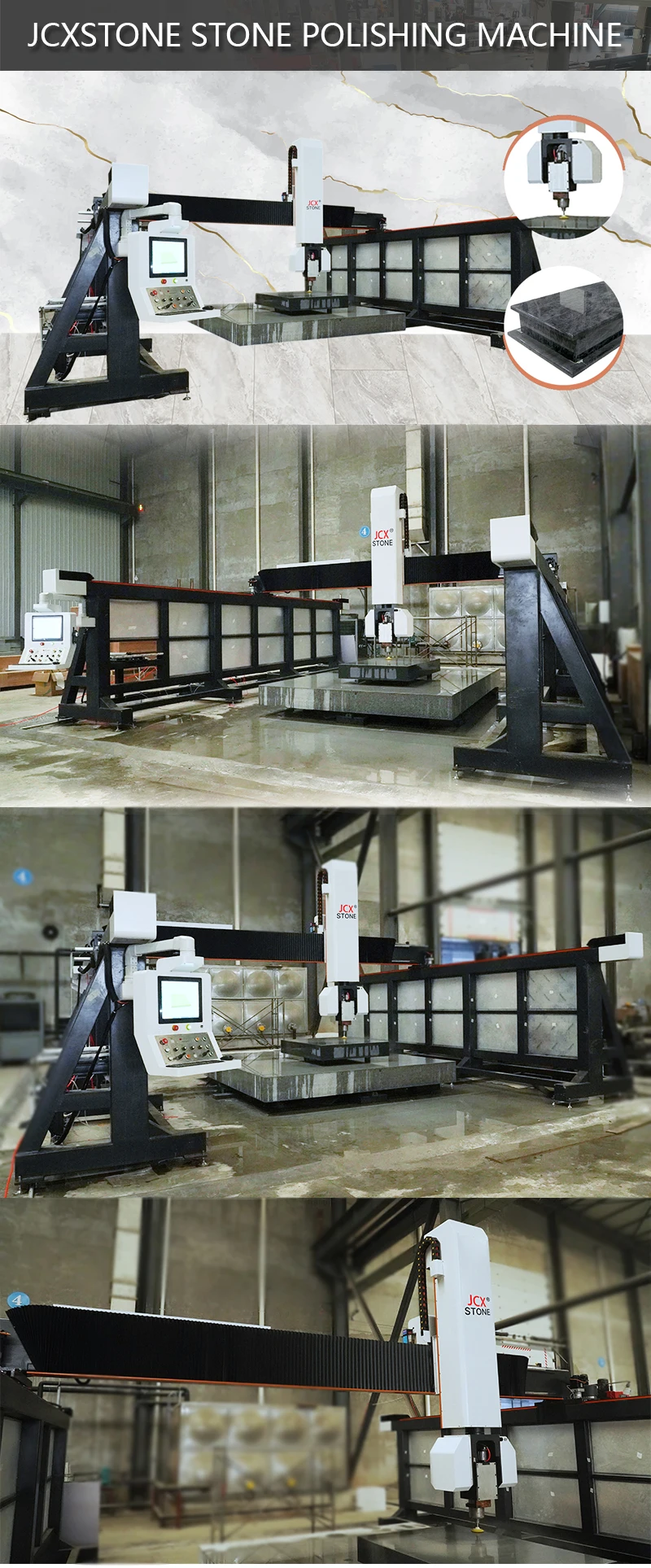

control system | Upgrade the latest five-axis system |

Mechanical head rotation Angle | 0-360 degree |

Mechanical head tilt Angle | 0-Any Angle within 90 degrees |

Polishing machine | Customized polished motor, waterproof and high temperature resistant |

Polishing speed | 1-2500mm/mim |

Kind of drive | High wear-resistant widened 35 square rail + imported high precision ball screw |

Drive mode | Key parts of high precision servo control/Angle tilt high precision ori drive servo motor |

Control mode | Five-axis professional control system with wireless handle |

Welding table | Customized welding table according to customer needs |

Programming mode | Modify data directly in the operating system |

Filling method | Automatic oil lubrication |

Spare wearing parts | Travel switch, screw, wrench, etc |

Packaging | Plastic packaging (wrap film pearl cotton) |

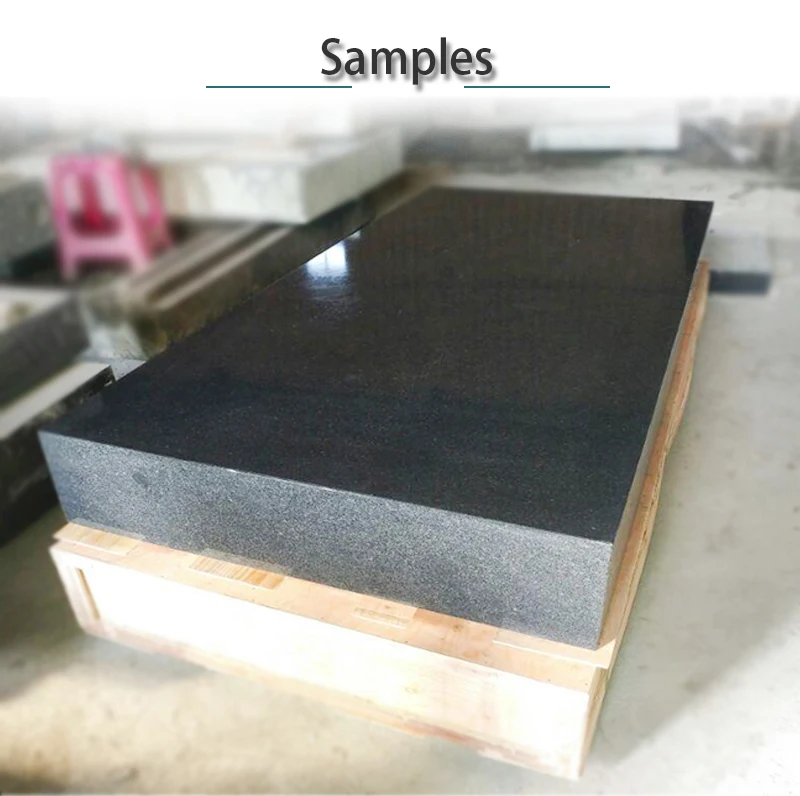

Boundary dimension | Approx. Length 7000mm wide 5000mm high 3200mm |

Machine body weight | about 7000kg |

PS: All the working area and specifications can be customized according to your requests.

Technical requirements for developing customized five sided grinding machines:

1. We will use central water outlet and pneumatic pressure to ensure fixed pressure and uniform brightness for the spindle

2. Processing stroke meets 6000 * 4000 * 500 fully automatic polishing

3. Polishing the center of the spindle to ensure that the abrasive does not burn, and the tool handle is connected by BT40 or sub buckle

4. We will use I-beam and iron plate welding to ensure that the crossbeam does not deform

5. The XY Z-axis linear guide rail will use 35 rails to ensure stable operation without shaking

6. Meet the five sided polishing of 500mm thick products

7. Adopting a five axis head, it can rotate at any angle and achieve edge chamfering