Price:US $5500.0

Overview

Essential details

Type:

Filling Machine

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory, Cosmetics industry

Showroom Location:

None

Condition:

New

Application:

Food, Beverage, Cosmetic

Packaging Type:

Cartons

Packaging Material:

Wood

Automatic Grade:

Semi-automatic

Driven Type:

Electric

Voltage:

220/110V

Place of Origin:

Zhejiang, China

Brand Name:

HZPK

Dimension(L*W*H):

1100*780*1450mm

Weight:

320 KG

Warranty:

1 Year

Key Selling Points:

Easy to Operate

Machinery Capacity:

600-1200BPH

Filling Material:

Milk, Water, Oil, Paste, Liquid, Cream

Filling Accuracy:

±1%

Marketing Type:

Hot Product 2019

Machinery Test Report:

Not Available

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor, PLC, Cylinder

tube diameter:

15-50mm

Filling volume:

5-50ml/50-250ml

tube length:

60-220mm

pringting letter size:

2*3m

Air pressure:

0.55-0.65mpa

After-sales Service Provided:

Video technical support, Free spare parts

Supply Ability

Supply Ability

20 Set/Sets per Month

Packaging & delivery

Packaging Details

Our products are packed in boxs. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxs are damaged or other situations happen, please contact us in time.

Port

NINGBO/SHANGHAI

Lead time:

Quantity(sets) 1 - 5 >5 Lead time (days) 30 To be negotiated

Why Choose Us

1. More than 10 years manufacture in packing machine

2. 11 years alibaba supplier

3. 100% QC inspection before shipment

4. 12 months warranty

5. Product Certificated by CE

Product Description

Introduction:Semi Automatic tube filling and sealing machine is suitable for filling of liquid or paste, sealing tubes, batch number and manufacture date printing. Features:1. Using ultrasonic sealing and the seal is more stable. 3. The body is made of 3 o 4 stainless steel and has a long service life. 3. Features of rational struction, complete function, easy operation, accurate filling, stable running, as well as low noise. 4. it is an ideal equipment for plastic tubes and multiple tubes filling and sealing in cosmetic, pharmacy, foodstuff, adhesives etcindustries. 5. This machine complies with CE certification.

Detailed Images

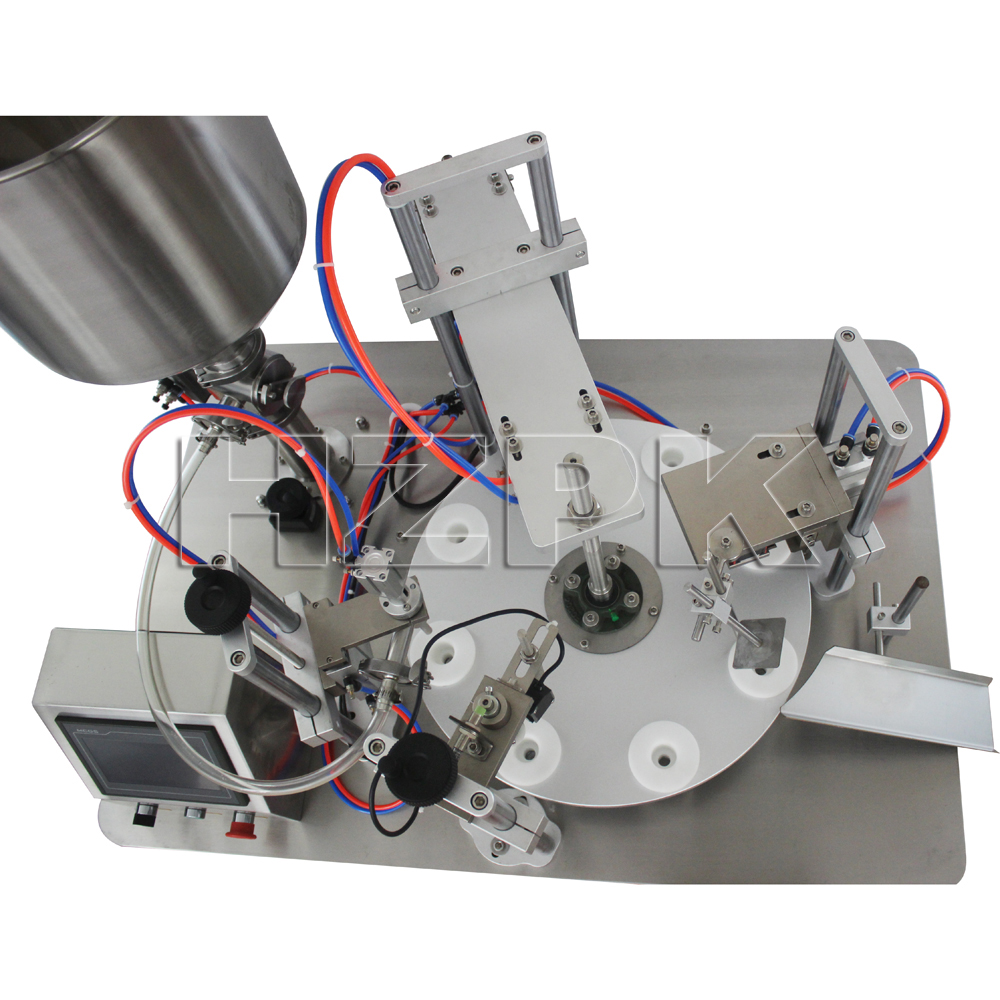

Working Disk

8-station workbench

You only need to manually place the tube, and automatically perform mark-matching, filling, sealing, cutting off the remaining material, and ejecting the tube.

Control Panel

The control panel is mainly composed of touch screen , power switch, start up button, emergency switch, easy to operate.

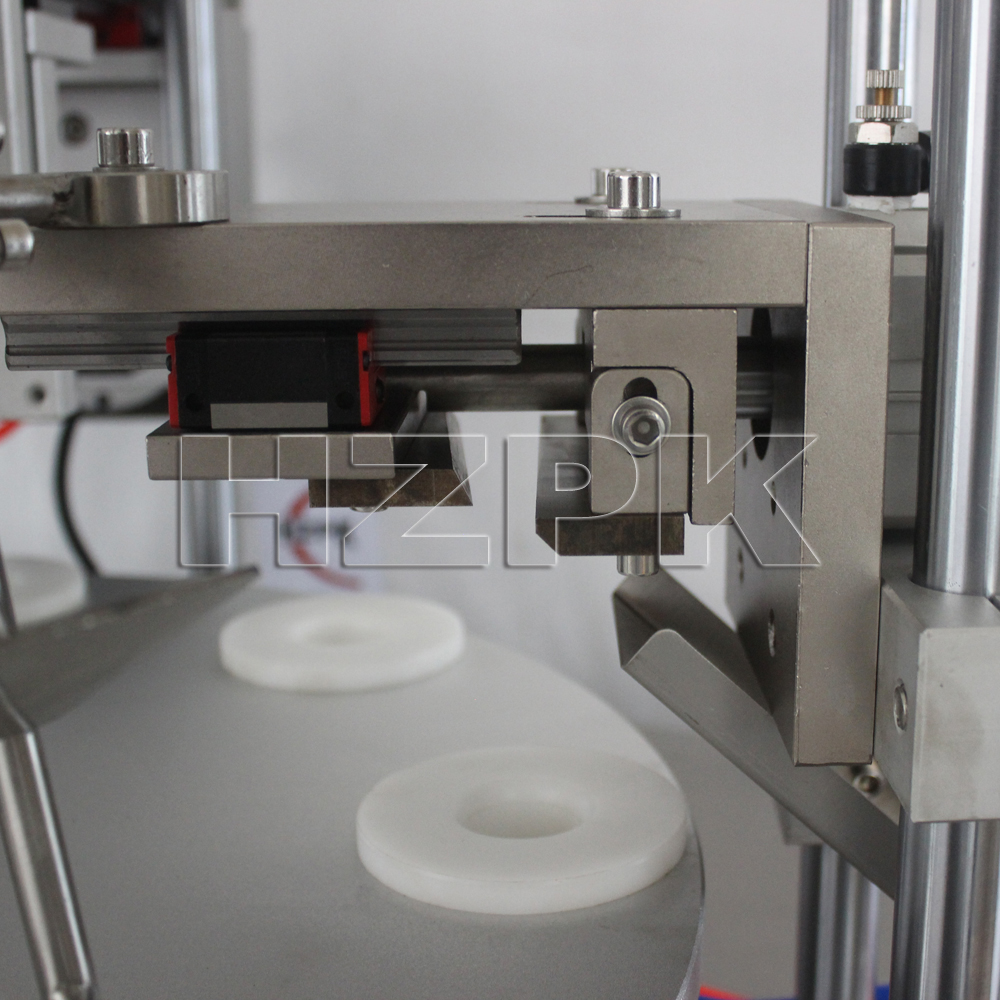

Mark Sensor

Automatically detect whether there is a tube on the station, and if there is a tube, it will automatically be marked for the next step.

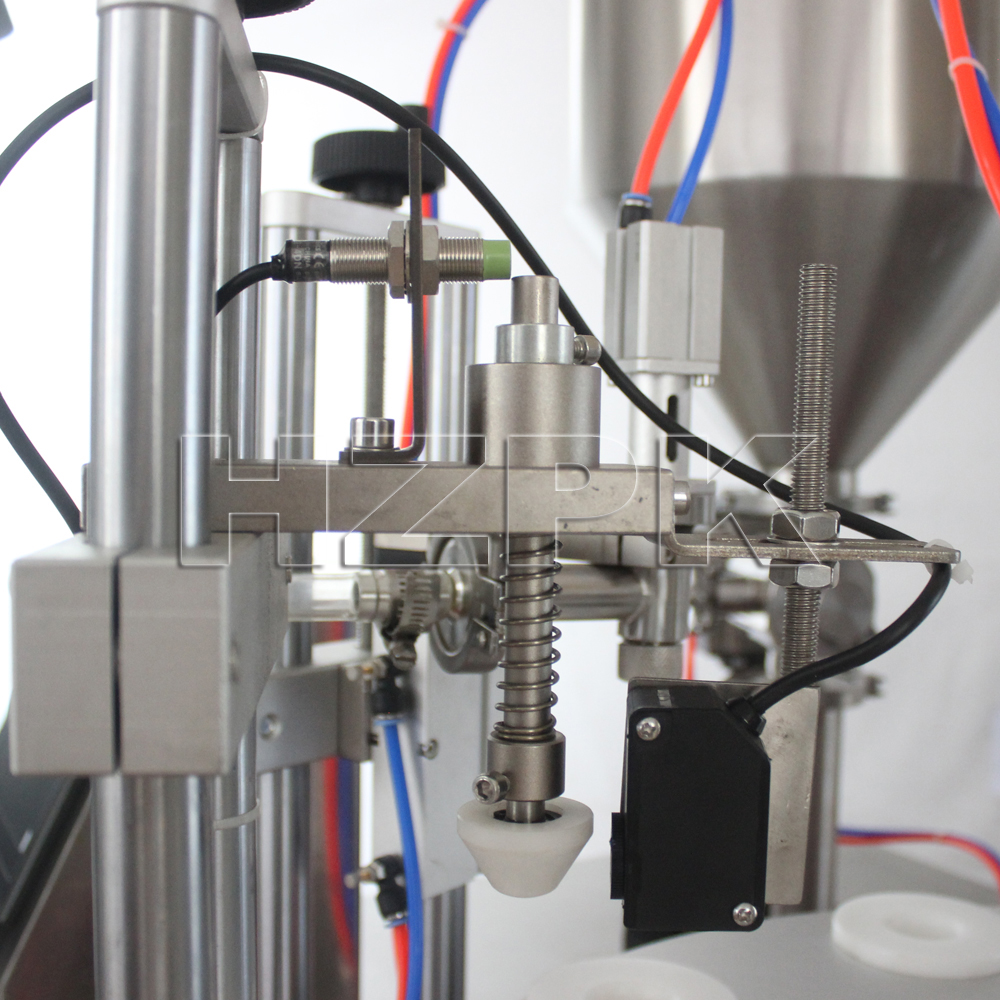

Filling Nozzle

The filling nozzle and other parts in contact with the material are made of 304 stainless steel, which meets the food hygiene requirements. In addition, the anti-drip structure can be customized.

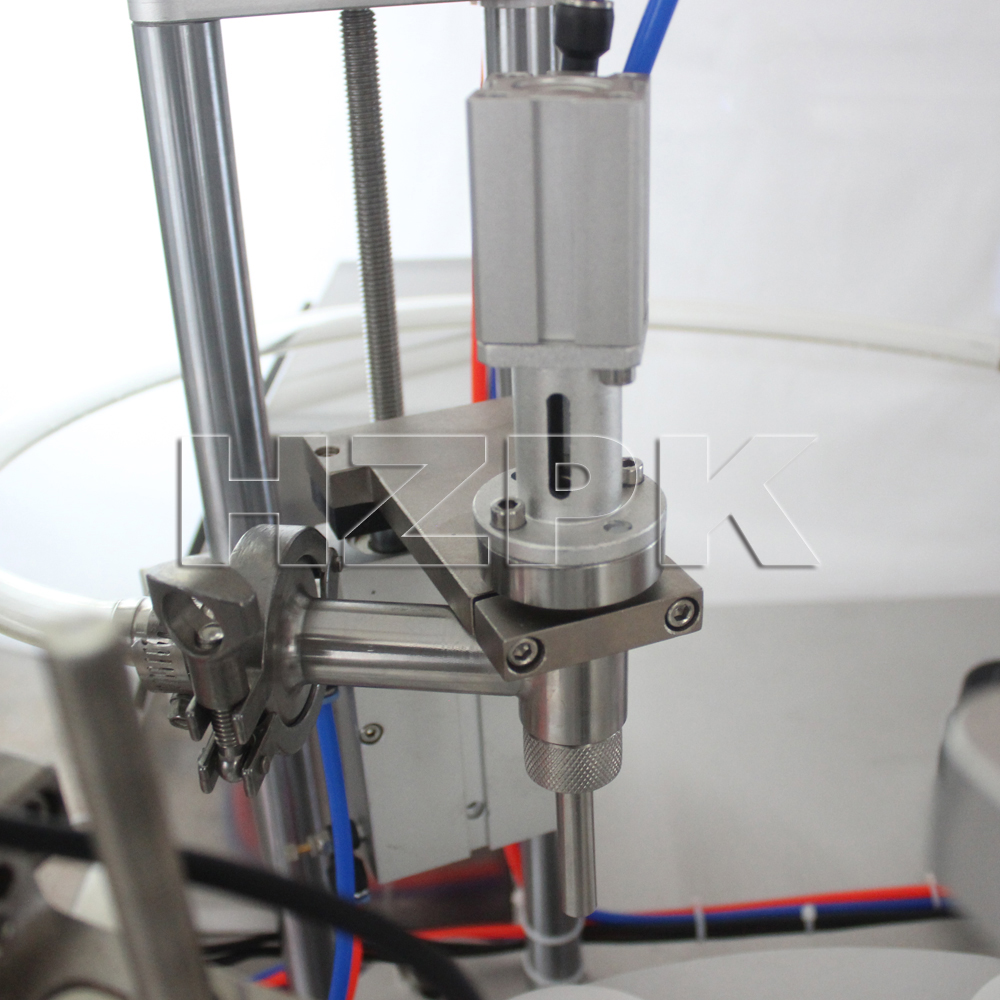

Ultrasonic Sealing

The ultrasonic system seals the hose with fast sealing speed, good effect and beautiful seal.

Cutter

After sealing, the remaining material is automatically cut to keep the hose tail flat

Mould

A set of molds is suitable for a hose of one height and diameter, and different hoses require different molds to switch