Price:US $18000.

Overview

Essential details

Type:

Multi-Function Packaging Machine

Applicable Industries:

Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops

Weight (KG):

450

Showroom Location:

Egypt, Canada, United States, Viet Nam, Pakistan, Mexico, Thailand, South Korea, Chile, Australia

Condition:

New

Function:

FILLING, Laminating, Sealing, Wrapping

Application:

Chemical, Commodity, Food, Machinery & Hardware

Packaging Type:

Bags, Belt, CANS, Cartons, case, Film, Foil, Pouch, Stand-up Pouch

Packaging Material:

Plastic, laminated falm

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

220V 50/60Hz

Place of Origin:

Zhejiang, China

Brand Name:

Zon Pack

Dimension(L*W*H):

1300*820*1400

Warranty:

1 Year

Key Selling Points:

Easy to Operate

Marketing Type:

Ordinary Product

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

Production Capacity:

40bag/min, 50bag/min, 30bag/min

After-sales Service Provided:

Engineers available to service machinery overseas

Machine type:

Automatic Packing Machine

Name:

Zon Pack automatic machine

Packing speed:

15-70 Bags / Min

Bag type:

Punching Bag

Main function:

Automatic Form

Usage:

Food Snack

Control of packing machine:

PLC

Film thickness:

0.06-0.12mm

Main Function:

Automatic Form

Packaging & delivery

Selling Units:

Single item

Single package size:

60X60X70 cm

Single gross weight:

68.000 kg

Package Type:

Packing with woonden box

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 15 To be negotiated

Video Description

Product Description

Product Application

It is suitable for packing grain, stick, slice, globose, irregular shape products such as puffy food, snacks, candy, chocolate, nuts, pistachio, pasta, coffee bean, sugar, chips, cereals, pet food, fruits, roasted seeds, frozen food, small hardware, etc.

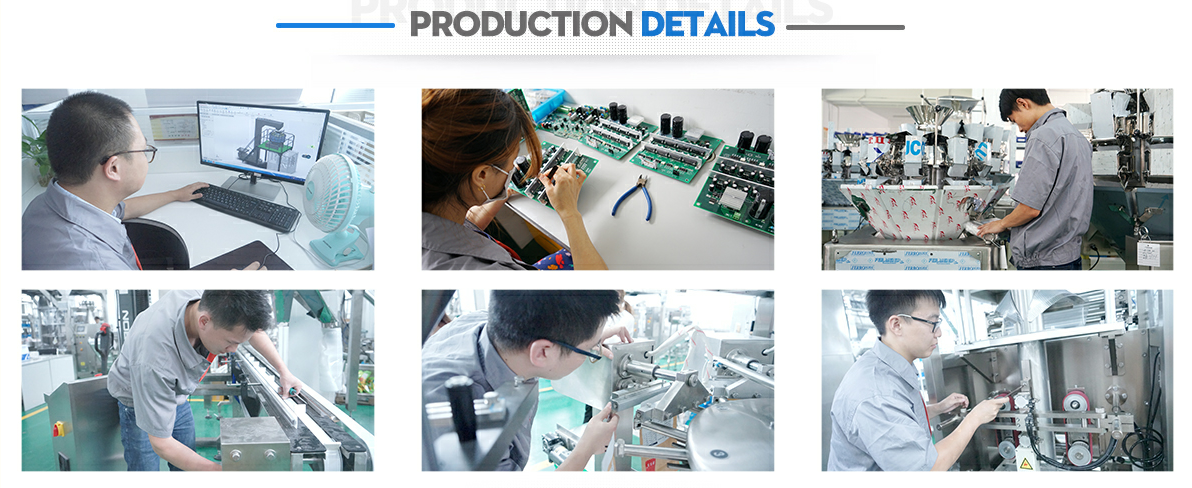

Main Features

1. Adopting PLC from Japan or Germany to make machine run stable. Touch screen from Tai Wan to make operation easy.

2. Sophisticated design on electronic and pneumatic control system makes the machine with high level of precision, reliability and stability.

3. Single-belt pulling with servo of high precise positioning makes film transporting system stable, servo motor from Siemens or Panasonic.

4. Perfect alarm system to make problem solved quickly.

5. Adopting intellectual temperature controller,the temperature is controlled to ensure neat sealing.

6. Machine can make pillow bag and standing bag (gusseted bag) according to customer's requirements. Machine also can make bag with punching hole & linked bag from 5-12 bags and so on.

7. Working with weighing or filling machines such as multihead weigher, volumetric cup filler, auger filler or feeding conveyor, process of weighing, bag making, filling, date printing, charging (exhausting), sealing, counting and delivering finished product can be completed automatically.

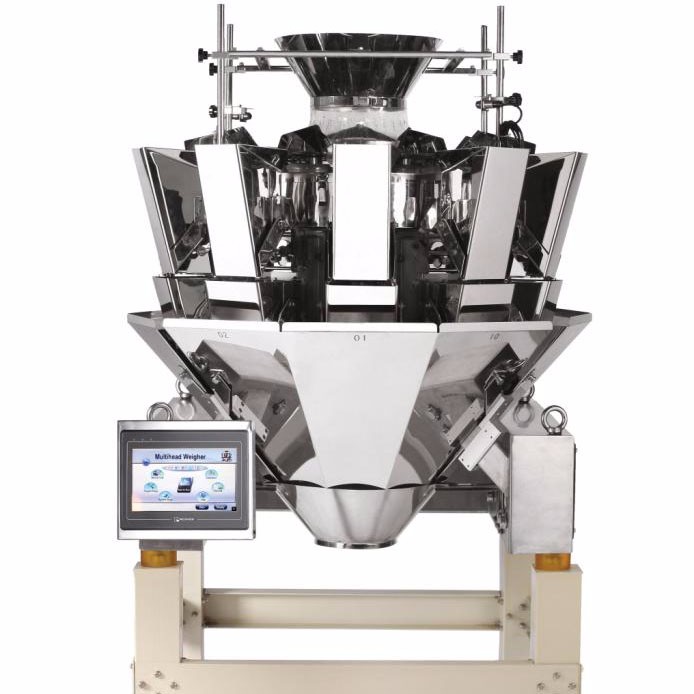

Detailed Images

PS:

some option of our packing machine

1.Our factory have many models of packing machine.Such as ZH-V420,ZH-V520,ZH-720,ZH-930 packing machine.And the bigest difference is they have different acception of the max width with film.This is ZH-V420 packing machine,and it can packing max width of film is 420mm.So you can choose one as your required.

2.We have many different device for packing machine.Such as nitrogen device,vacuum device ,gusseted device,4 edges sealing device,perfrating device,code printer device and so on. You can choose the device according to your required.

3.Our packing machine is fit for pre-printed film, but we can print date and bar code.

If you have any prolem please tell me now,please click' Chat now'.,our professional female Coco will solve your problem.

Related Products

Bucket Elevator

ZH-10 heads weigher

Checking machine

ZH-4 heads linear weigher

ZH-520 Packing machine

ZH-720 packing machine

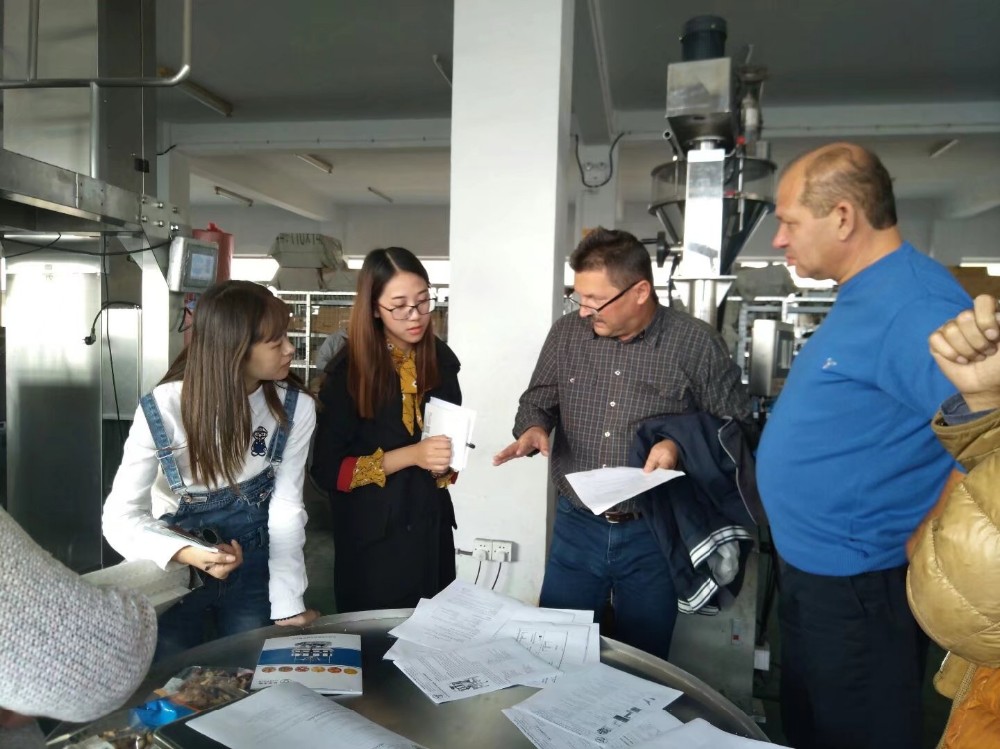

Our customers

We all know that the price of a machine is not a little money. So every year, many customers come to our factory to see for themselves and make themselves more secure.We welcome you come to our factory and believe that you will be very satisfying for our machine.

Our Service

Pre-Sales Service:

1.If you are interested in our Machine, We can send your video about the details of its working process.

2.If you want to come to our our factory for better understanding of machinery, we will have a professional introduction from our team, and try to solve your any problem.

After-Sales Service:

1.We will train your engineer to install our machine. You can send your engineer to our factory or we dispatch our engineer to your company. We will introduce your engineer how to install the machine and how to fix problem.

2.Some times if you can not fix the problem in your country, we will send our engineer there if you need us to support.Of course, you need to afford the round trip flight ticket and accommodation fee.

3.For spare parts support: For machine in guarantee period, if spare part broken, we will send you the parts free and we will pay the express fee. And please send us the spare parts back. when machine is out of guarantee period, we will provide you the spare parts in cost price