Price:US $59800.

Overview

Essential details

Plate Type:

Screen Printer

Applicable Industries:

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Printing Shops, Food & Beverage Shops, Other, Advertising Company, Glass bottle, Wine bottle, Bottle decoration

Condition:

New

Place of Origin:

Guangdong,China

Brand Name:

LC

Usage:

Label Printer, Bottle Cup Jar printer

Automatic Grade:

Automatic

Color & Page:

Multicolor

Voltage:

380VAC,3-PHASE 50HZ/60HZ

Dimensions(L*W*H):

2700*2000*1700mm

Weight:

1240 KG

Certification:

CE

Warranty:

1 Year

After-sales Service Provided:

online support, Video technical support

Key Selling Points:

Automatic

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Other, Pressure vessel, CCD image positioning, electrostatic precipitation

Model:

LC-CNC105

Printing shape:

Round,Square,Oval, complicated-shape

Feedng and unloading:

U-shaped structure

Printing precision:

±0.02mm

Air compression:

0.5-0.6Mpa

Printing speed:

2600PCS/H (Round); 2100PCS/H(Oval); 2000PCS/H(Special shape).

Printing size(Round):

Dia 20-100mm, Length 20-130mm(Round)

Printing size(Oval):

Width 20-100mm, Length 20-130mm(Oval)

Conveyors size:

1500*60*1100MM.2500*60*1100mm

Optional function:

CCD image positioning system

Supply Ability

Supply Ability

100 Set/Sets per Month

Packaging & delivery

Packaging Details

the machine will be packaged in wooden case to ensure safety

Port

ShenZhen port of China

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 30 To be negotiated

Video Description

Product Description

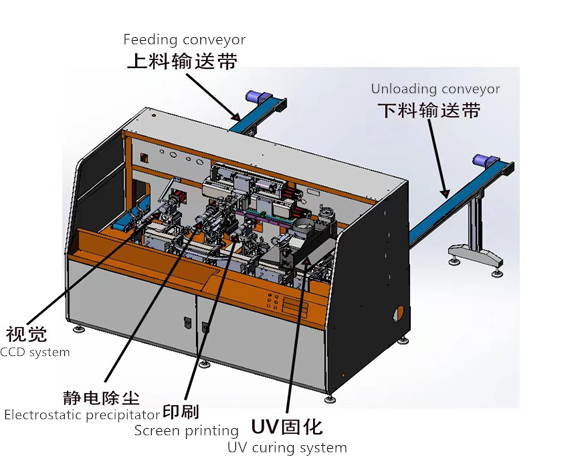

Multi Colors CNC Full Auto Servo System Screen Printing Machine with CCD image positioning system

This model is a fully automatic screen printing machine, suitable for cylindrical, square and special-shaped products. The printing ink can be selected from high temperature ordinary ink, UV ink and ordinary ink.Adopt high-precision divider, full mechanical transmission system, mechanical pre-positioning system, fast printing speed, stable and reliable quality, convenient

and quick debugging.

U-shaped loading and unloading structure can save a lot of space; can print multicolor by multitime.

multi shape bottle automatic screen printer

Features: This machine is suitable for screen printing on the surface of various special-shaped containers such as round, oval, square, special-shaped bottles (with different curvatures on both sides) and double-sided two-color containers. It has the advantages of convenient and quick debugging and installation, stable and reliable operation, strong versatility and high printing efficiency. This machine can be equipped with screen plate heating, ink scraper heating function and UV light curing furnace at any time, and can use ordinary self-drying ink printing, UV ink printing, high temperature solid ink printing, with high adaptability.

Multi Colors CNC Full Auto Servo System Screen Printing Machine with CCD image positioning system

Outstanding advantages for the following bottle shapes and situations:

1. The oval bottle can be printed with the same color on both sides at the same time, which greatly improves the printing speed, and can also be printed on one side.

2. The bottle with a square plane can be printed with the same color from one side to four sides at one time, and can also be printed on any surface from one side to four sides.

3. The triangular bottle can be printed with the same color from one side to three sides at one time,or one side can be printed on one side to three sides.

4. Polygonal bottles such as hexagonal and octagonal can be printed on one side to eight sides in the same color at one time, or one side can be printed on any surface from one side to eight sides.

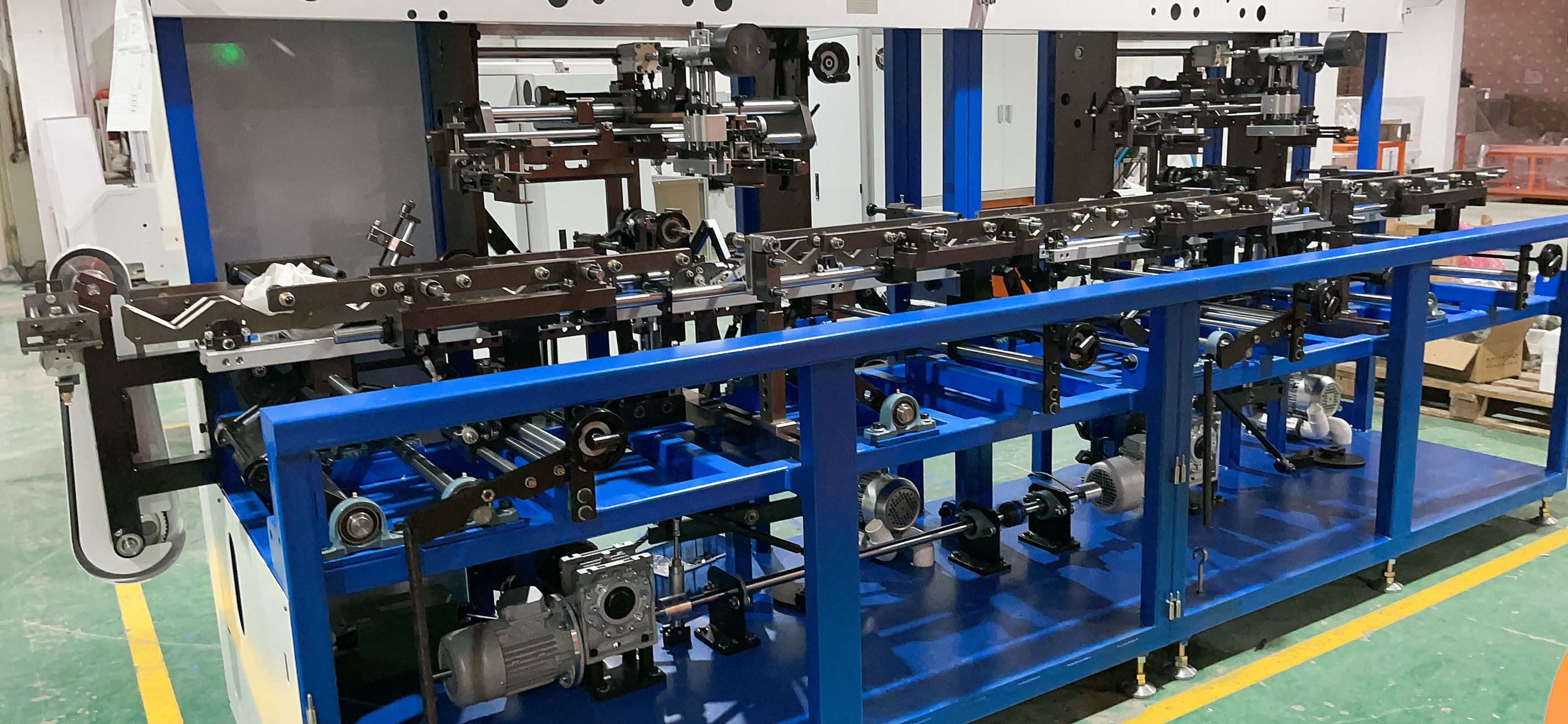

Machine structure features:

The structure of the machine is mainly composed of automatic bottle feeding structure, automatic dust removal device, automatic feeding structure of manipulator, position transfer structure of full servo system, and automatic printing main body (printing system). Using modular program-controlled processor and touch screen display control system, the operation is morestable. Less fixtures are easy to change the bottle shape, debugging and installation are simple, and the operation is more convenient. The machine is stable and high precision; you can also choose to install UV light curing system and stencil heating system, which is suitable for random switching between UV ink and high temperature ink.

glass bottle servo system screen printing machine

Product application range: This machine is suitable for glass product packaging, wine bottle packaging, cosmetic packaging, pharmaceutical and food packaging containers, and the material can be glass, plastic, ceramic, metal, etc. Ink printing application range: 1. UV ink printing (can be added according to customer requirements) UV ink printing, UV curing treatment can enter the packaging process. The UV treatment system of this machine, no matter what kind of bottle shape, can achieve sufficient UV light irradiation on the printing surface of the bottle, ensuring that the printing surface is fully illuminated by UV light. The ink adhesion is higher and the quality is more reliable. 2. High temperature ink printing (can be increased according to customer requirements) The machine can be equipped with the electric heating function of the screen frame, which can meet the requirements of customers for printing high temperature ink. This machine can also use high temperature color solid ink to print. 3. Ordinary self-drying ink printing The machine can also be printed with ordinary self-drying ink to meet the needs of products that need bronzing process. It can also be equipped with a robot to directly put the printed products on the oven. This saves time, labor costs and floor space

nail polish bottle printing Equipment character

1. Advanced PLC and touch screen operation display control system, with a high degree of automation. 2. High accuracy and efficiency and stability. 3. Main components used SMC, Panasonic, Schneider and Omron. 4. CCD Visual positioning system

Specification

Company Profile

Our company was founded in 1991 and has 30 years of production experience. At the same time, we are a 13-year Alibaba store,producing machines all over the world.

Foreign Cooperative Partners

Photo of Factory

Certifications