Products Description

Product Details

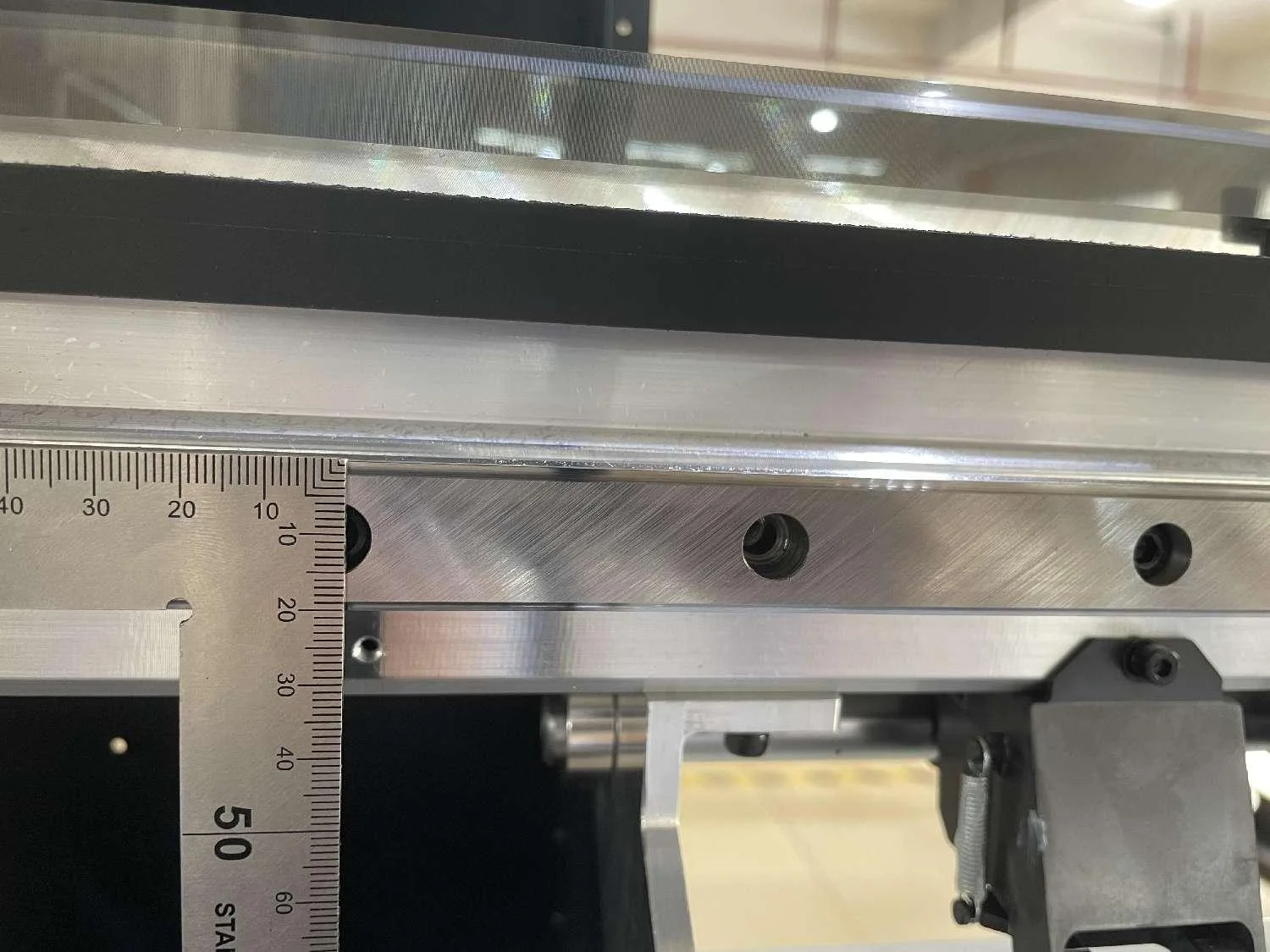

Rail beam

There are striped wave patterns on the top of the beam body, which enhances the overall rigidity and durability of the beam body and reduces deformation caused by excessive use or transportation time.

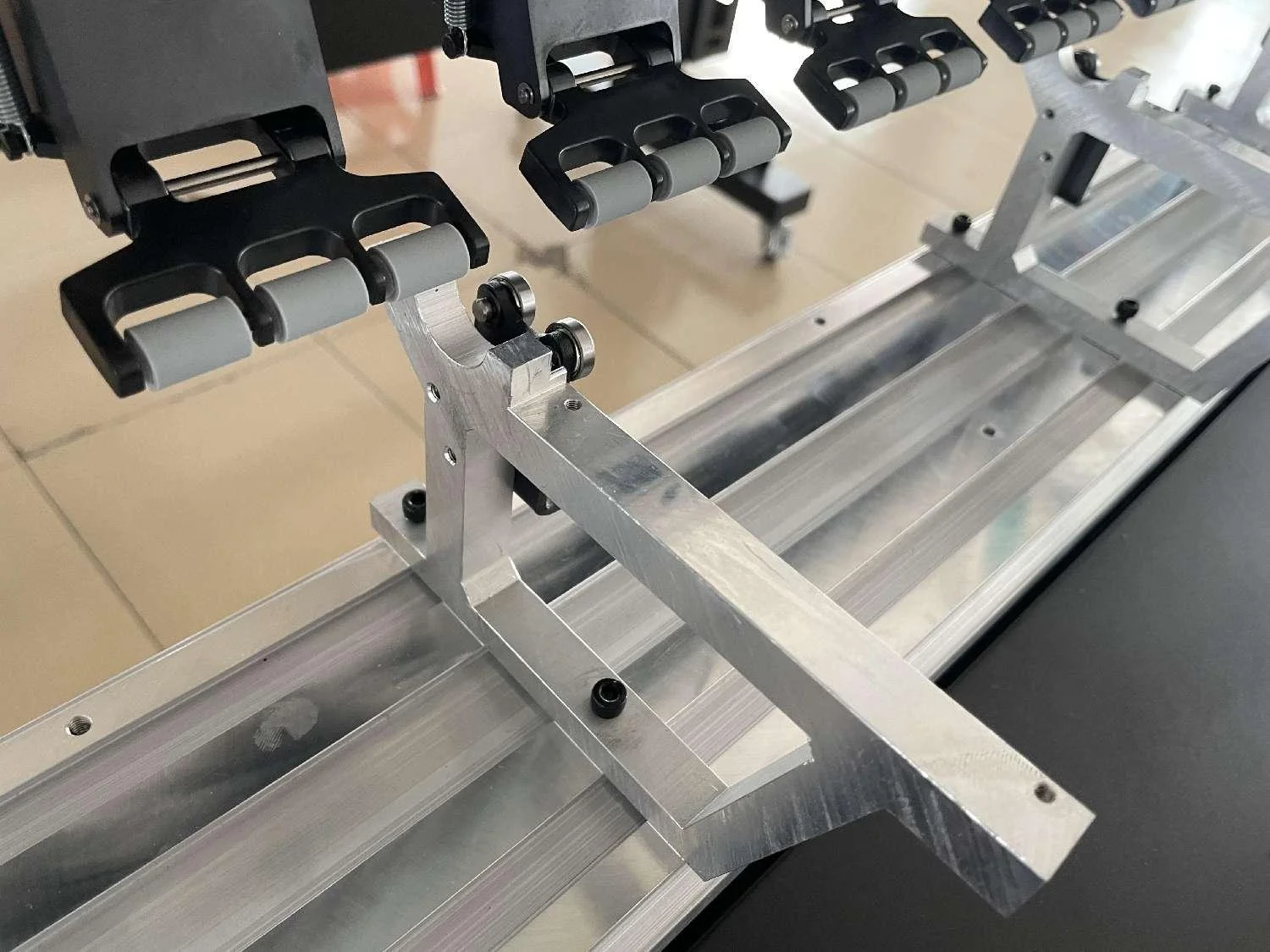

Platform support frame

It is composed of 12 support points and two CNC machined support plates to ensure that the platform accuracy is controlled within ≤ 0.01mm

Rails

Now they are all 2.0cm rails, and most of their peers use 1.5cm wide rails.

Pinch Roller

Cooperating with licker-in rollers ensures stable paper feeding without arching, and also improves the accuracy of stepping.

Rubber roller

Model A has a diameter of 15mm,It cooperates with the long pressure roller to improve the paper feeding accuracy and make the material convey smoothly

Side panels

The one-piece aluminum material is CNC processed and formed, and the main beam, the guide beam and the licker-in are connected at the same time, which greatly reduces the use of connecting parts and greatly improves the stability of the body and the stability of the paper.

Platform heating

can be heated in three stages of front, middle and rear platforms, and the printing image is heated evenly, which enhances the ink absorption of the material

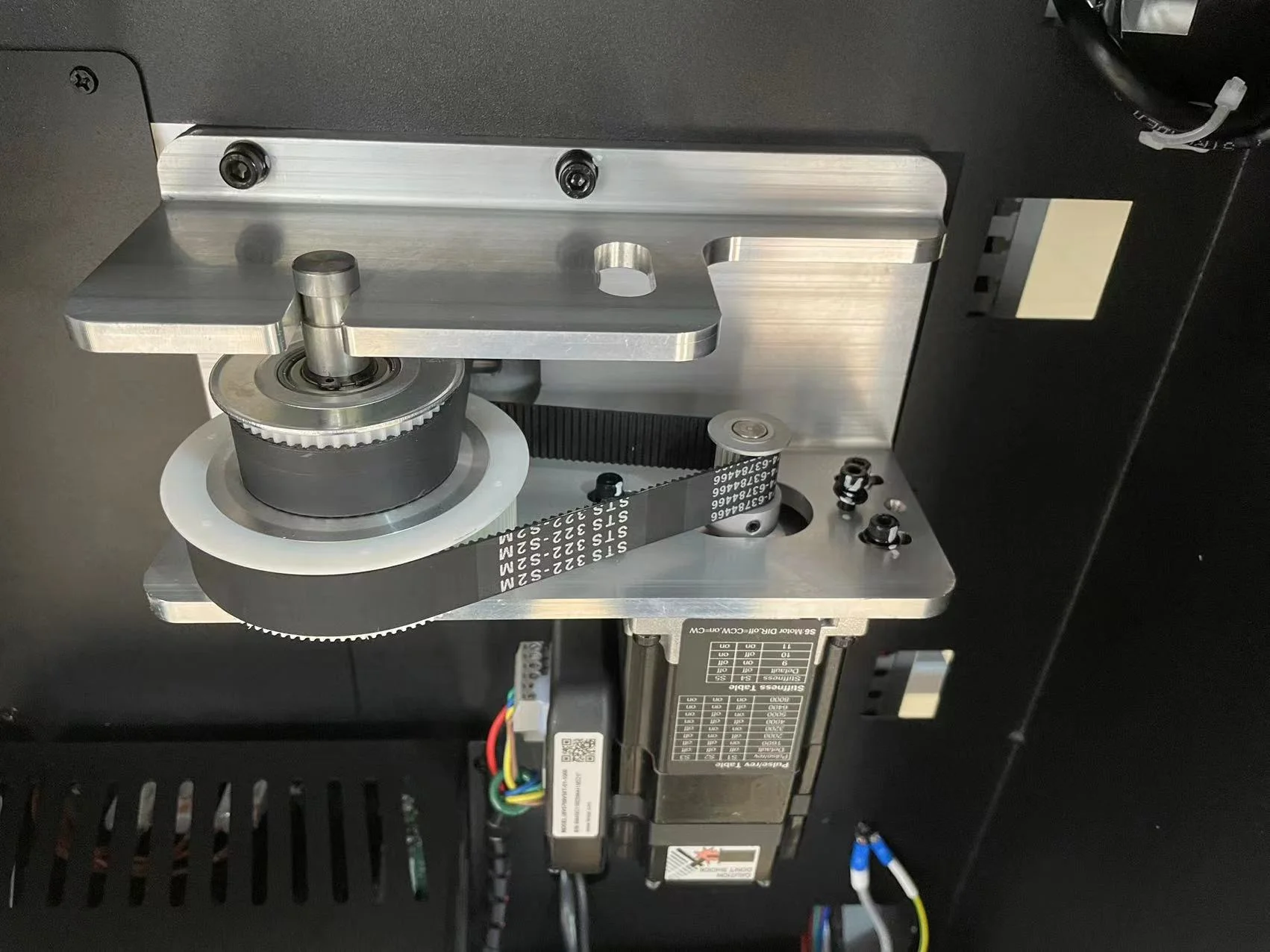

X-axis synchronizing wheel

One-piece CNC machining, with adjustable structure, convenient for later maintenance.

Anti-collision

Sensitive ultra-long anti-collision to protect the print head; touch emergency stop to prevent accidents during the printing process.

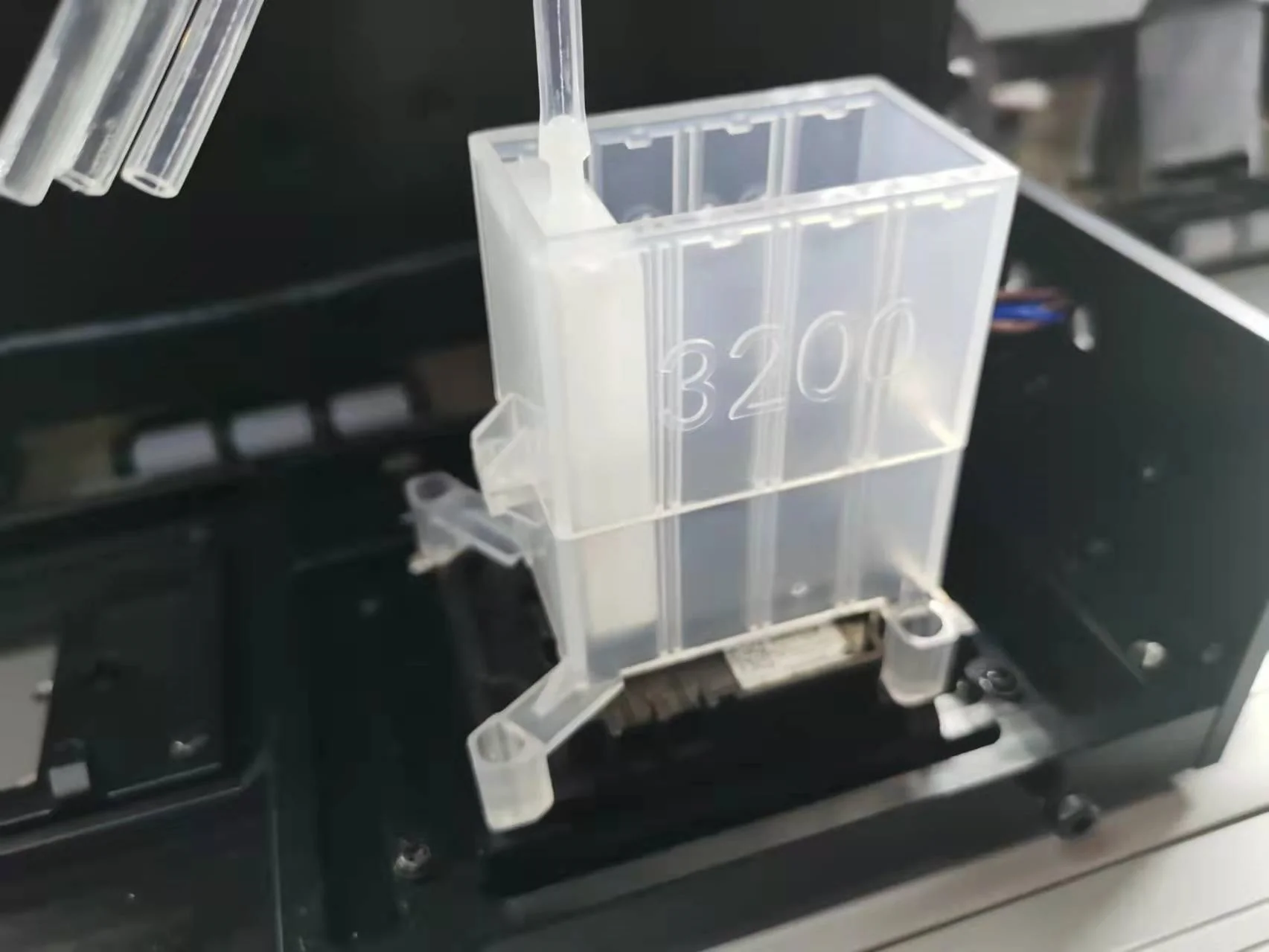

Lifting and lowering of the trolley

It can be adjusted physically by printing materials of different thicknesses.

Damper fixing device

The ink damper, print head, and print head bottom plate are uniformly fixed by the fixing frame, which effectively reduces the influence of the movement of the carriage during the printing process and ensures the smoothness of the ink

Ink tube

Each ink tube is individually labeled with the ink extension color, which is convenient for customers to install and maintain.