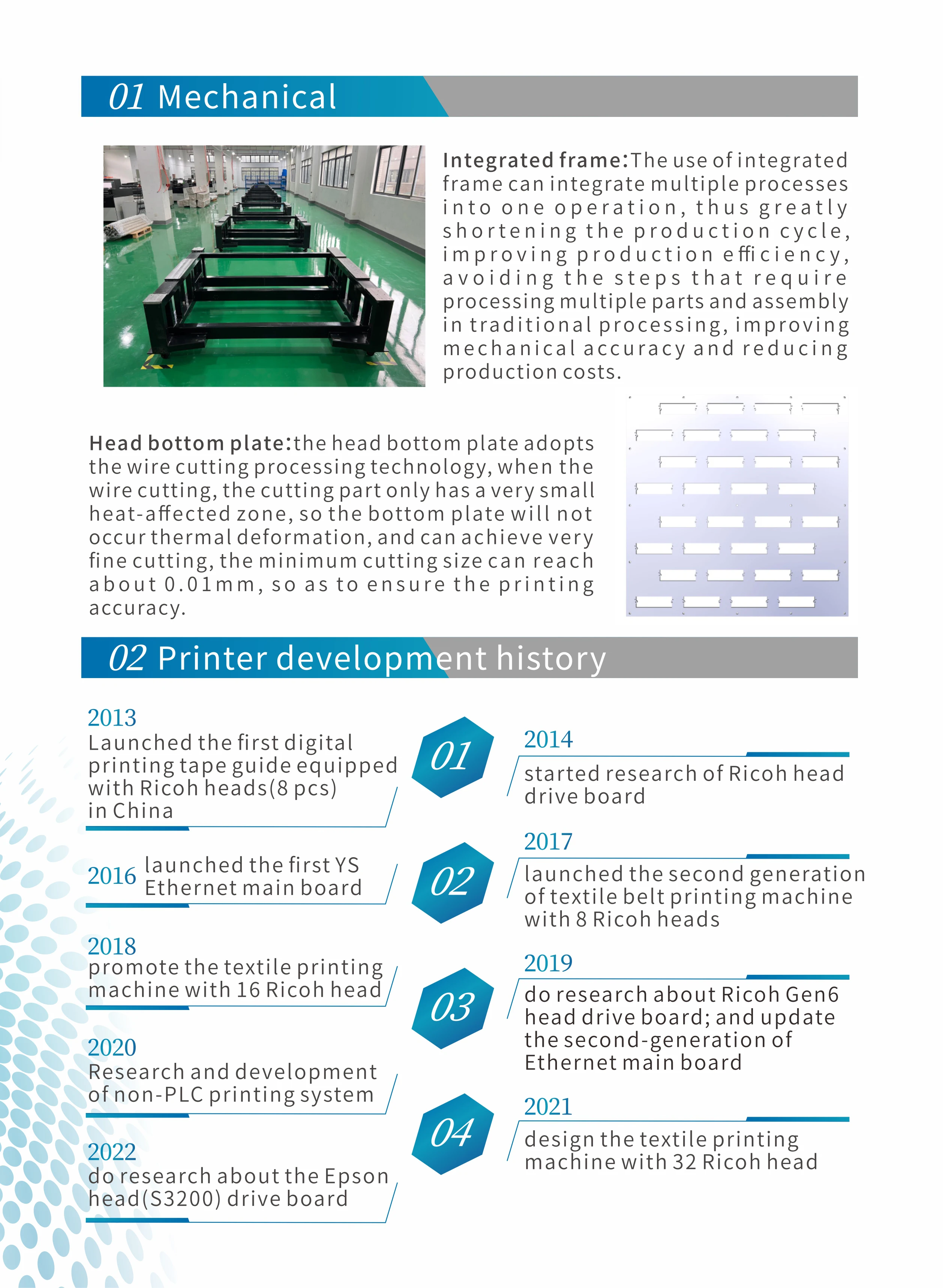

Products Description

Product Paramenters

MODELS WE HAVE

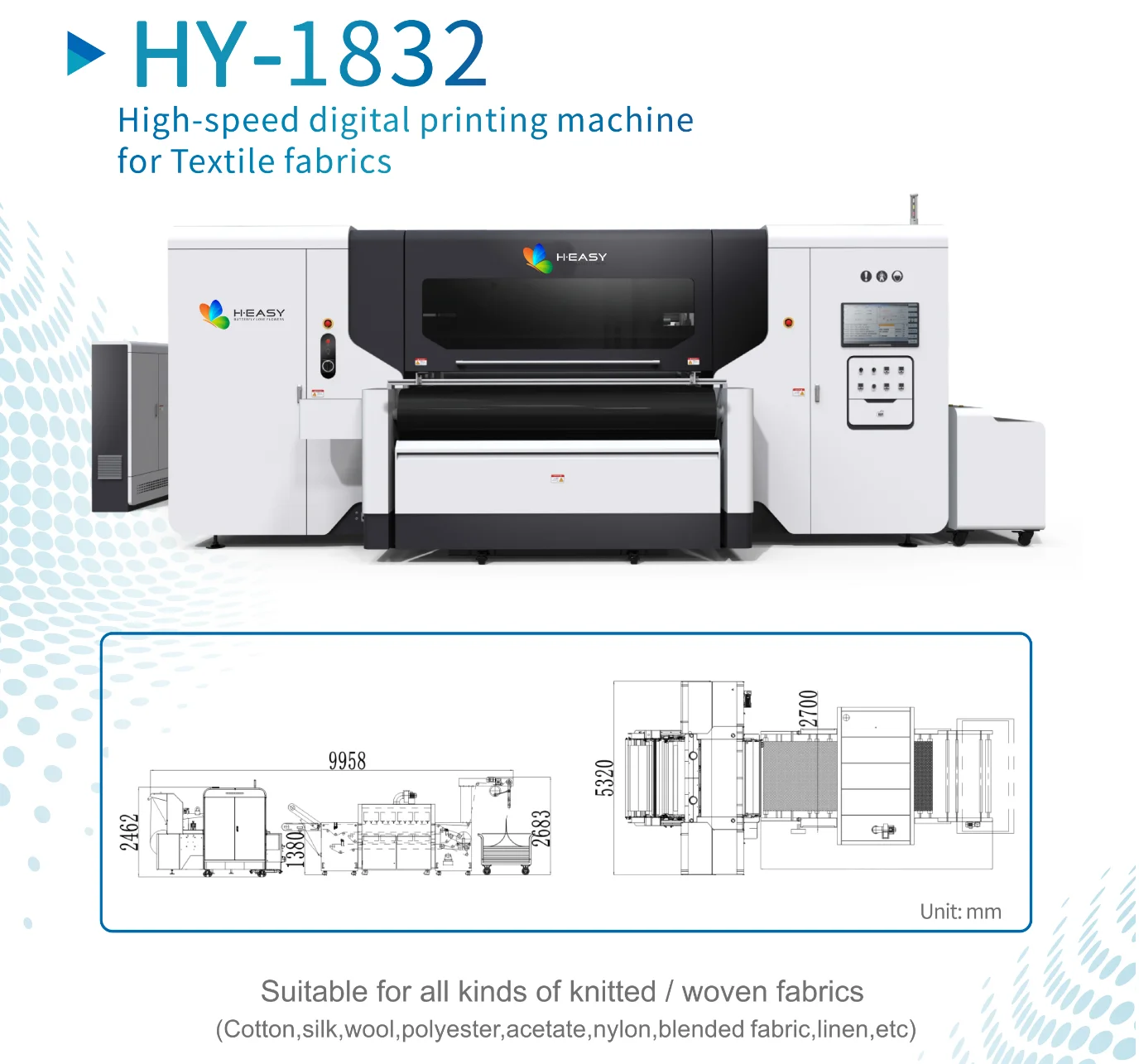

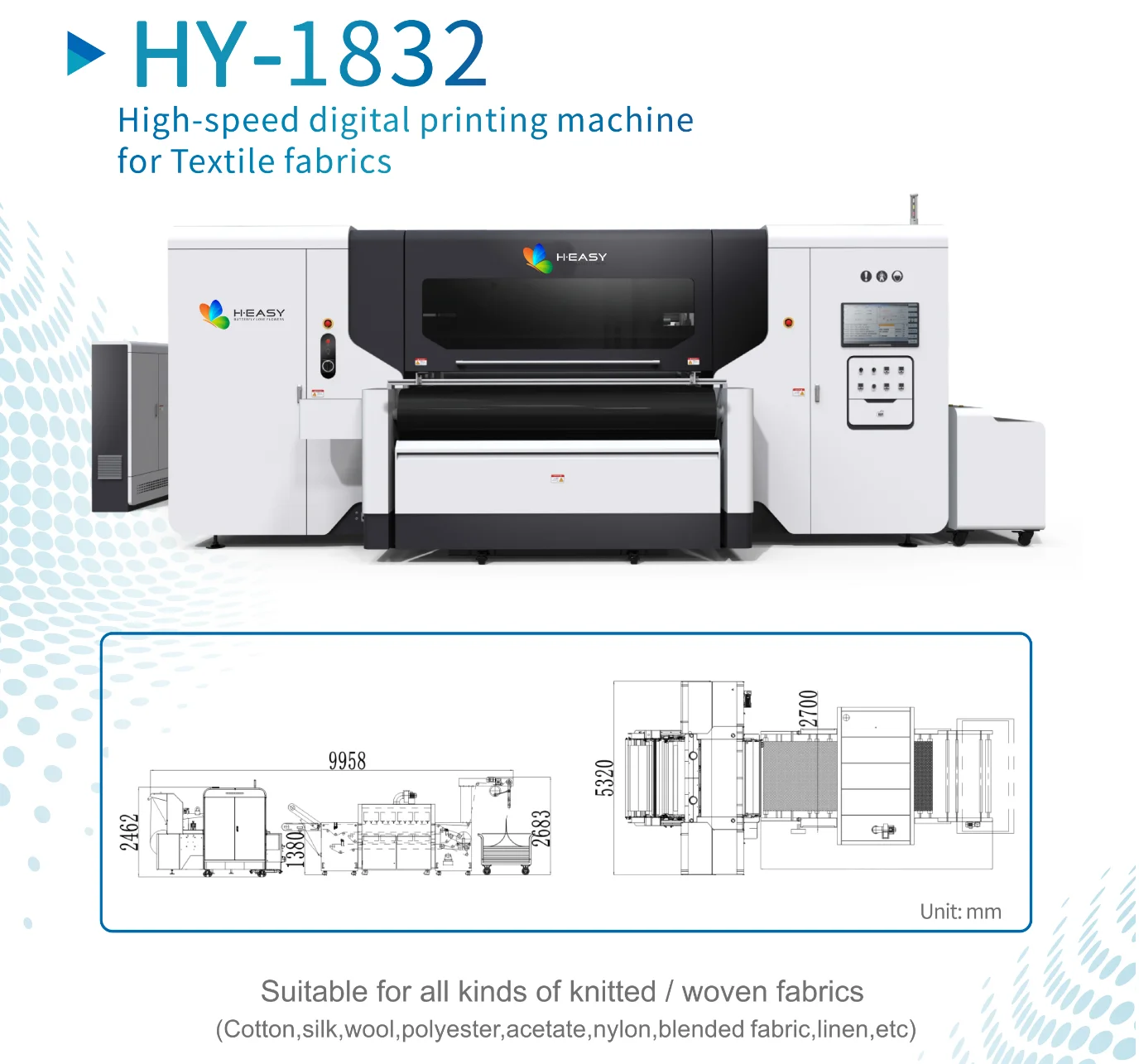

Product mode | HY-1832/2232/2632 |

Fabric conveyance mode | Adhesive belt with cleaning and heating system |

MaximumPrintwidth | 1900/2200/2600mm |

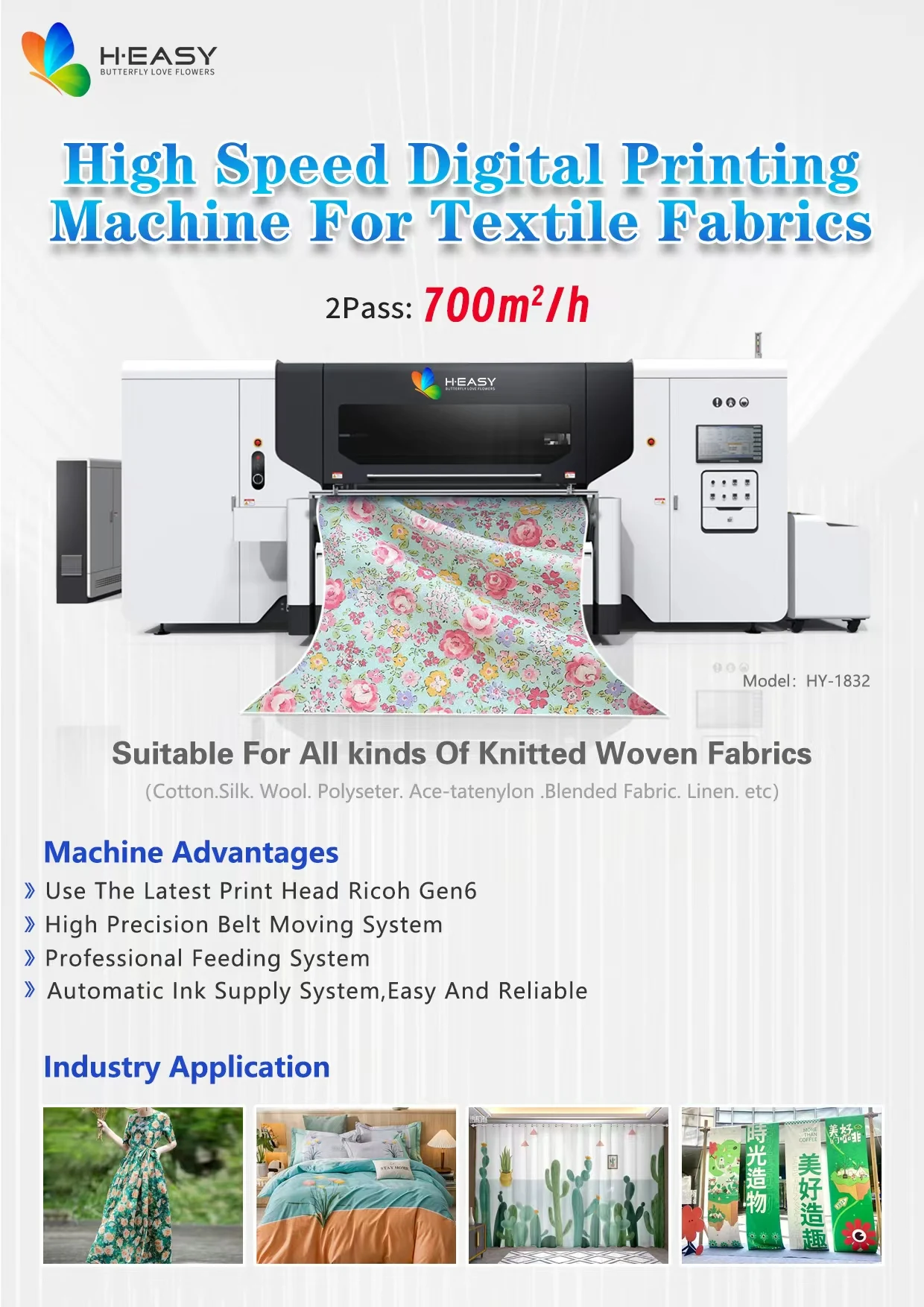

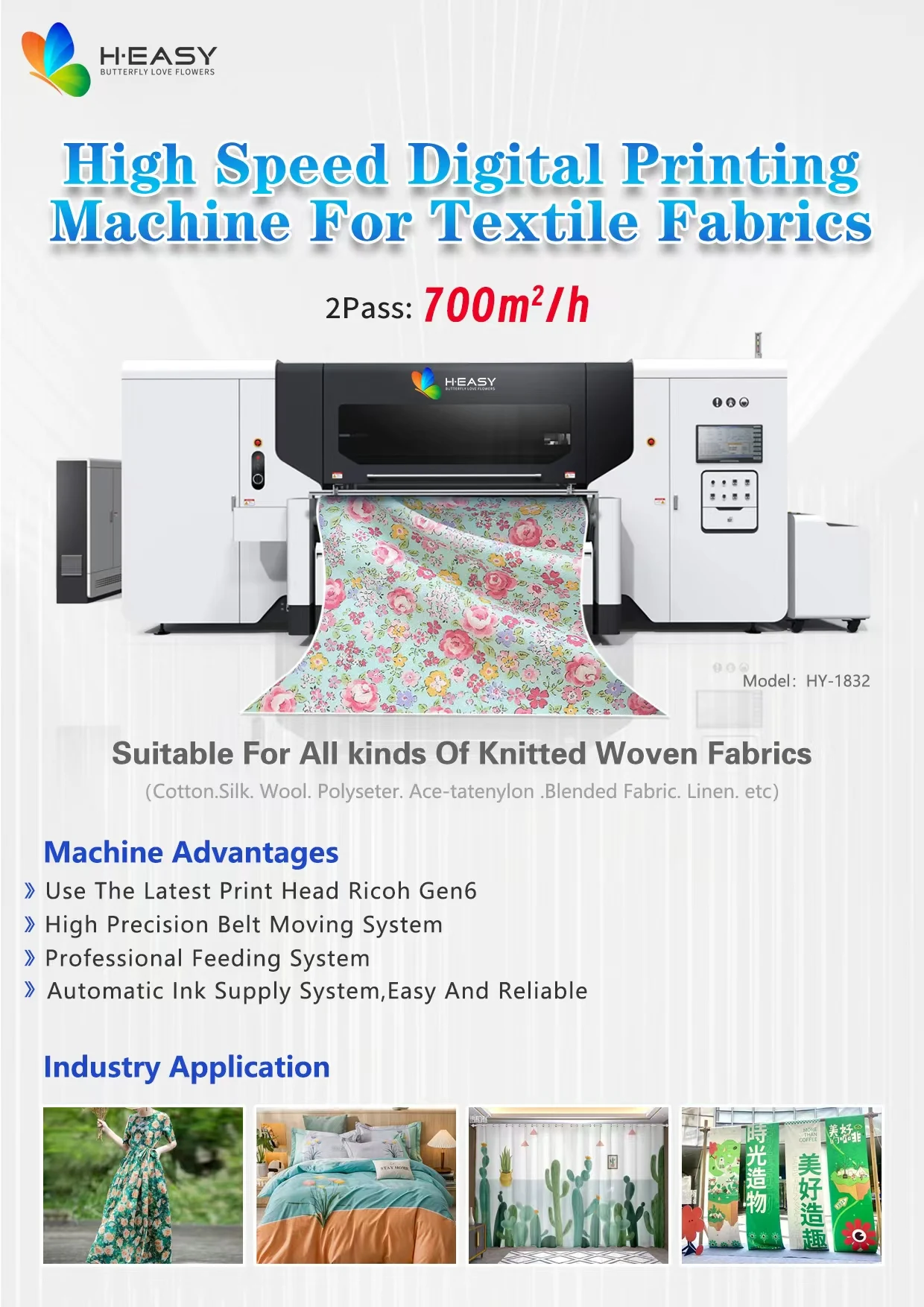

Speed | Gen6:1pass:1300m2/h 2pass:650m2/h |

Maximumprintingresoution | 2400 DPI |

RIP software | Neostampa / Texprint(origin) |

Printingpartintroduction | Automatic negative pressure ink supply, automatic car lifting.automatic positive pressure cleaning,automatic

moisturizingsprinkleranti-collision system. |

Main inktank | 15L |

Belt system introduction | Automatic drving and winding system,automatic cleaning guidebelt system, anti-pressure roller print, synchronous pressure roller. |

Dryer unit | 3 tiers industry dryer with off plane |

Ink Type | reactive/disperse/acid/pigmentink |

InterfacePowervoltage | Optical fiber |

Printhead height | Height adiustable 1.5-30mmto adapt mediumofdifferent thickness |

Powervoltage | 380V 3L+N+G(with independent reliable effective earth wire) |

Powerfrequency | 50HZ/60HZ+1HZ |

PowerConsumption | Printer:40kw;oven:6KW |

Workshop Condition | Temperature:20-30°C,humidity:50-65% |

Effective width |

| 1900mm | 2200mm | 2600mm |

Printer | 5300mm*3450mm*2220mm (L*W*H) | 5700mm*3450mm*2220mm (L*W*H) | 6100mm*3450mm*2220mm (L*W*H) |

Dryer | 6400mm*3800mm*2700mm (L*W*H) | 6800mm*3800mm*2700mm(L*W*H) | 7200mm*3800mm*2700mm(L*W*H) |

Ink Cabinet | 1760mm*700mm*995mm(L*W*H) |

Weight | Printer:6200Kg;The bakery:5000kg; | Printer:8000Kg; | Printer:10000Kg; |

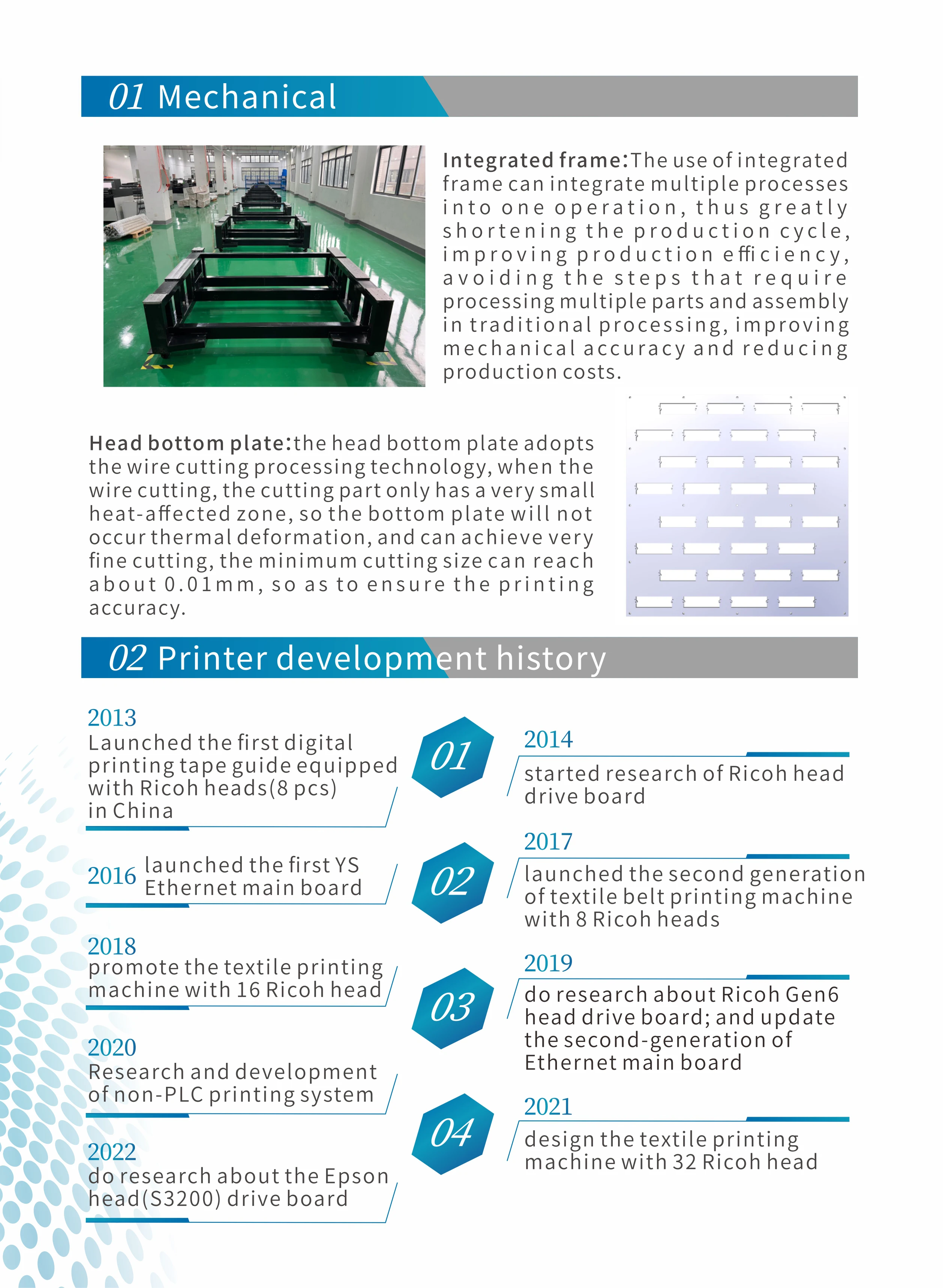

Product advantage

Production Process

PRINTING PROCESS

Do you know different fabrics use different ink?

CHOOSE THE CORRECT INK MEETING YOUR NEEDS!

Name | Scope of application | Advantages |

Reactive Ink | Suitable for cotton, rayon,silk and natural fiber fabrics. | 1. Process shorten, good effect. 2. Personalized customization, no limited by color. 3. Low pollution.

|

Disperse lnk | Disperse ink direct printing: Suitable for polyester fabrics | 1. Good penetration, color fastness. 2. Personalized customization, noimitedbycolor. 3. Low pollution. |

Acid Ink | Suitable for silk, wool, nylon etc. | Bright colors |

Pigment Ink | Used for any kinds fabric | 1. Environmental,noneed washing. 2. Printing processis simple. 3. Sample printingin minutes. 4. Can be used forall fabrics. |

DIFFERENT INK, THE PROCESSING IS DIFFERENT.

THERE ARE TWO PROCESSING AS BELOWS: