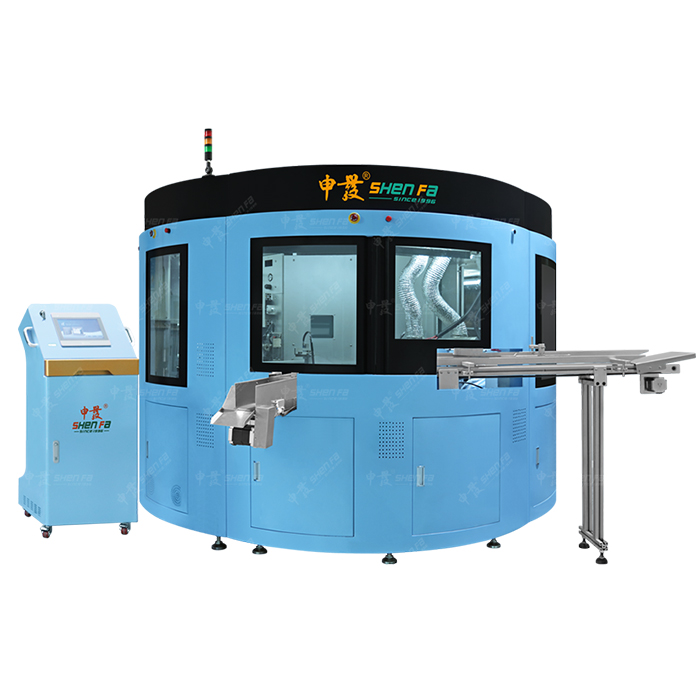

Mass Production Automatic Cosmetic Tube Printing Machine

| Price | $126.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Plate Type:

Screen Printer

Applicable Industries:

printing and packaging company

Condition:

New

Place of Origin:

Guangdong, China

Brand Name:

EASY

Usage:

Tube Printer

Automatic Grade:

Automatic

Color & Page:

Multicolor

Voltage:

380v

Dimensions(L*W*H):

3000x3000x2150mm

Weight:

5000 KG

Certification:

CE

Warranty:

2 years

After-sales Service Provided:

online support, Field installation, commissioning and training, Video technical support

Key Selling Points:

High Productivity

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Bearing, Motor, PLC

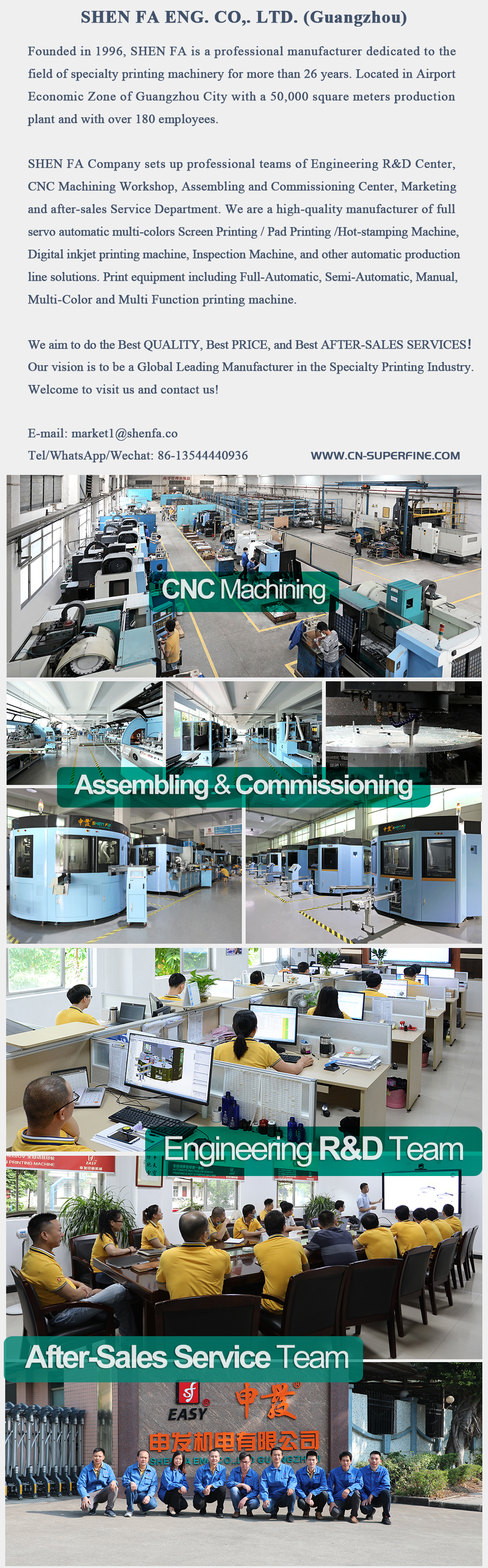

Company advantage:

Manufacturer Direct

Customization:

Available

Product name:

Auto Tube Printing Machine

Application:

Cosmetic Tube

Marketing Type:

New Product 2022

Printing color:

1-7 colors

Color/station:

7 color / 20 station

Printing type:

Fully Automatic

Printing speed:

80pcs/min

Supply Ability

Supply Ability

10 Set/Sets per Month

Packaging & delivery

Packaging Details

Exported wooden case

Port

Guangzhou, China

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 30 To be negotiated

Products Description

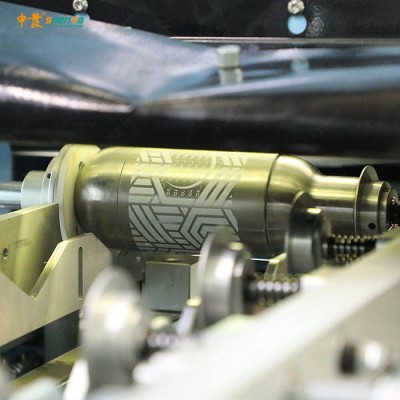

SF-SHR720 Seven color screen printing machine

SF-SHR720 Varnishing + Six color screen printing machine

SF-SHR720 Varnishing and five color screen printing + hot stamping machine

SF-SHR720 Varnishing and four color screen printing+ 2 hot stamping machine

This equipment is designed with high precision ( tolerance control is less than 0.2mm)

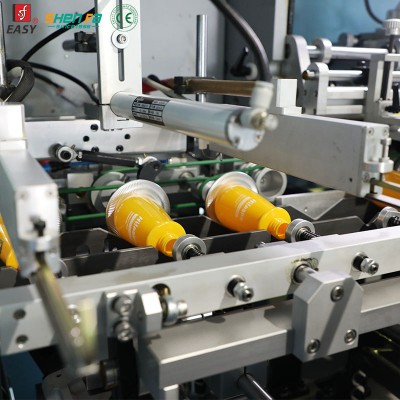

Automatic silk screen overprinting and hot stamping, it adopt independent servo variable frequency speed regulating device. The printing speed can reach up to 80pcs/min.

Servo gearless design, faster replacement of fixture, simpler, less vulnerable parts.

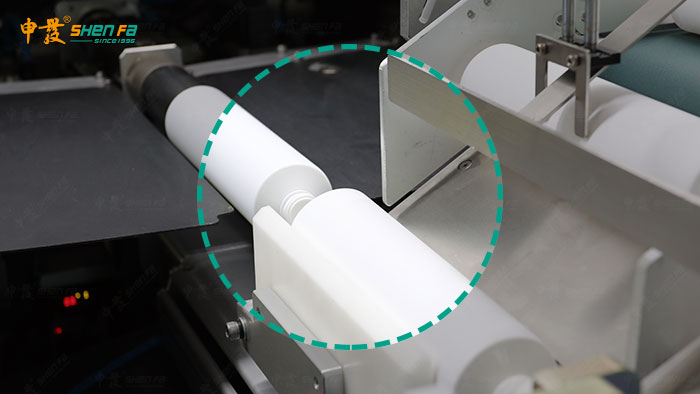

1. Auto Loading

2. Static Dedusting

3. Flame Pre-treatment

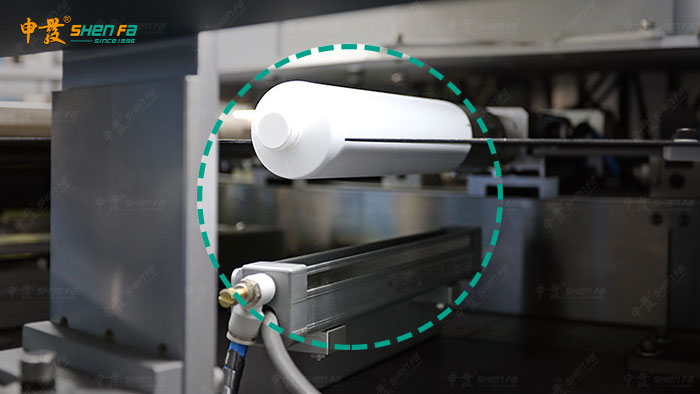

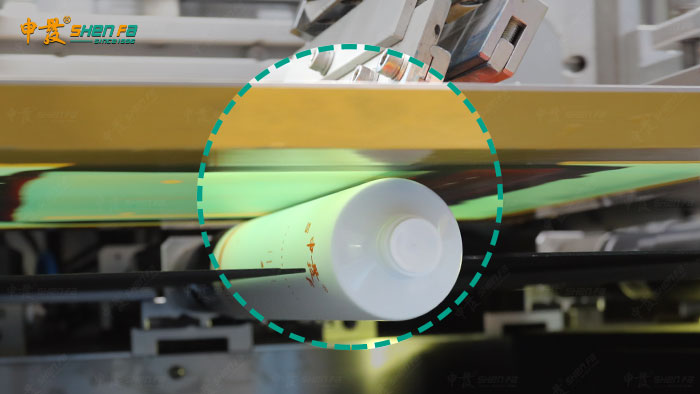

4. 1-8 Colors Screen Printing

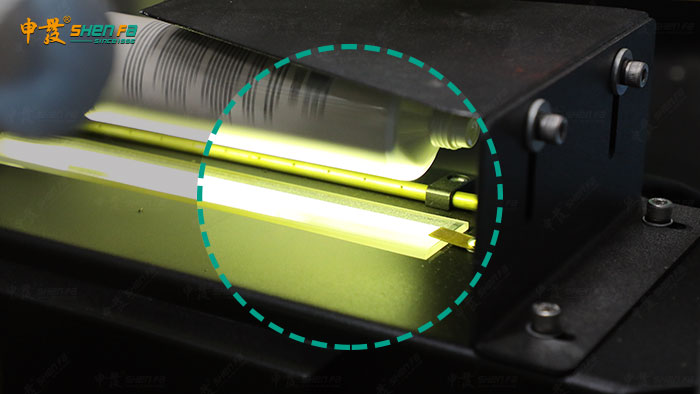

5. UV Curing

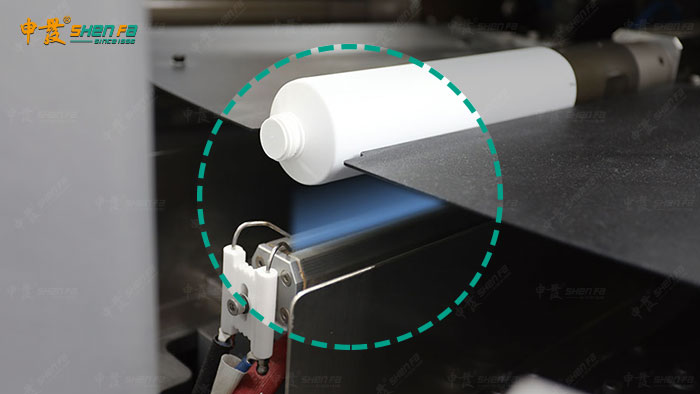

6. Hot Foil Stamping

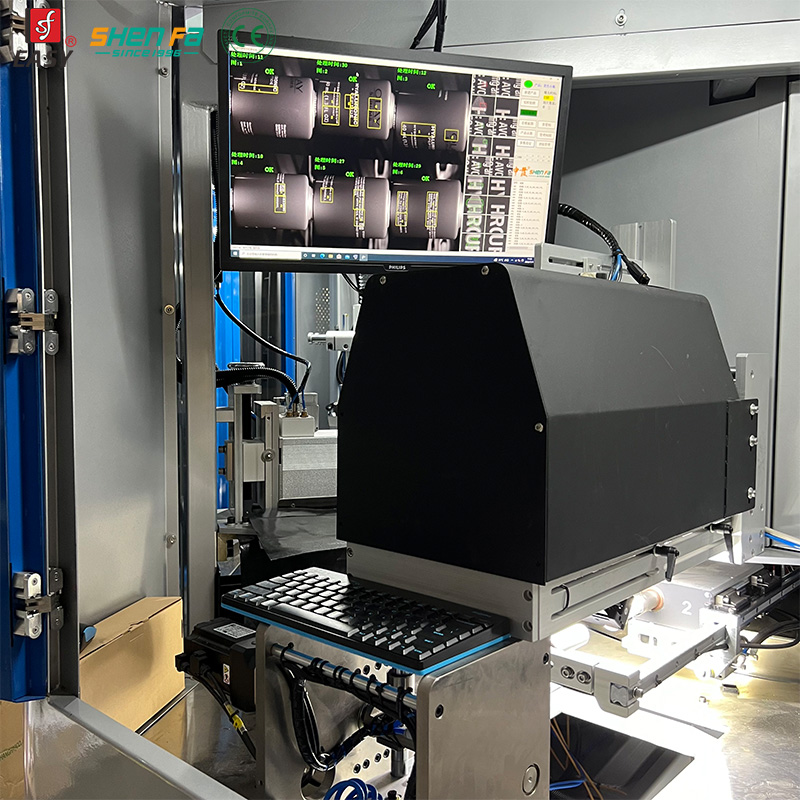

7. Camera QC Inspection System

The machine has also the option to equip camera QC inspection system to check every printed bottles. If there is printing defective product, it will be removed out from the conveyor.