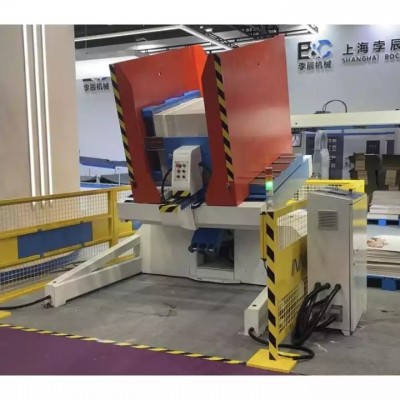

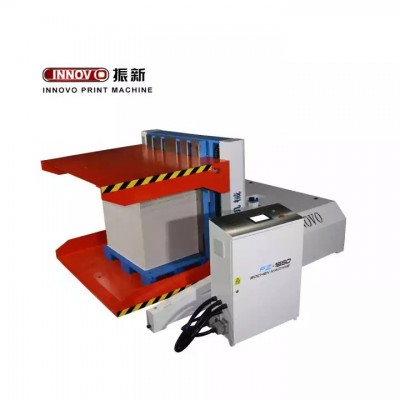

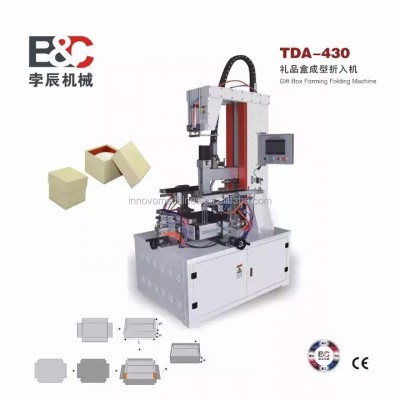

Automatic paper pile scrap removing machine

| Price | $26.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Warranty:

1 Year

Type:

Other

Applicable Industries:

Manufacturing Plant, Printing Shops, Advertising Company

Showroom Location:

None

Video outgoing-inspection:

Provided

Machinery Test Report:

Not Available

Warranty of core components:

1 Year

Core Components:

PLC, Motor

Condition:

New

Application:

Machinery & Hardware

Packaging Type:

Bags, Film

Packaging Material:

Plastic, Paper, metal

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

380V

Power:

17kw, 17kw

Place of Origin:

Anhui, China

Brand Name:

BC INNOVO

Weight:

4500 KG

Dimension(L*W*H):

2900*2200*2200mm

Key Selling Points:

Multifunctional

Max sheet size:

1220*1650mm

Loading weight:

1900kg

Platform width:

1800mm

Platform depth:

1235mm

Max pile height:

1600mm

Min pile height:

630mm

After Warranty Service:

Video technical support

Certification:

CE

Marketing Type:

Ordinary Product

Supply Ability

Supply Ability

20 Set/Sets per Month

Packaging & delivery

Packaging Details

vacuum bag

Port

Shanghai

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 25 To be negotiated

Video Description

Product Description

Automatic pile turning and aligning removing machine

Technical parameter:

Model | 1300 | 1450 | 1650 | 1900 |

Max sheet size | 800*3000mm | 1100*1450mm | 1200*1700mm | 1400*1850mm |

Min sheet size | 500*600mm | 500*600mm | 500*600mm | 500*600mm |

Loading weight | 1000kg | 1400kg | 2500kg | 3000kg |

Platform width | 1300mm | 1450mm | 1700mm | 1850mm |

Max pile height | 1600mm | 1600mm | 1600mm | 1600mm |

Min pile height | 800mm | 850mm | 850mm | 900mm |

Power | 380V,10KW | 380V,12KW | 380V,14KW | 380V,22KW |

Dimension | 2370*2390*1890mm | 2900*2200*2200mm | 3200*2300*2450mm | 3600*2900*2700mm |

Machine weight | 3500kg | 4800kg | 6500kg | 8000kg |

Machine brief introduction:

This machine is mainly used in printing and packaging industry, for pile turning, aligning, dust removal, etc. It is a necessary equipment to improve the work efficiency and printing quality.

Features:

1. It can remove the impurities such as paper fibers, paper scraps and printing powders.

Before printing: this machine can be used for removing the paper fibers, paper scraps and dust to improve the printing quality and reduce the defection rate about 80%. After printing: This machine can remove the printing powders, give a fast dry to the ink and prevents sticking together as well as paper back pollution. It can stop impurities such as paper fibers, paper scraps go into the printing machine to increase the service life of printing machine.

2. Paper separation.

By vibration and air jetting, the pile is filled with air cushion between the sheet by which the mis-feeding and double-sheeting can be avoided.

3. Aligning.

With the vibration platform and high pressure air jetting, the whole pile paper can be aligned at one time.

4. Turning.

For the piles of double sided printing paper, the pile turning will improve the work efficiency and lower the intensity of work. The working environment will be much better for workers.

5. High efficiency, easy operation.

For average, the processes of pile turning, powder removing, separation of paper and aligning only needs about 3 minutes. Easy operation, no need of special training for operation.

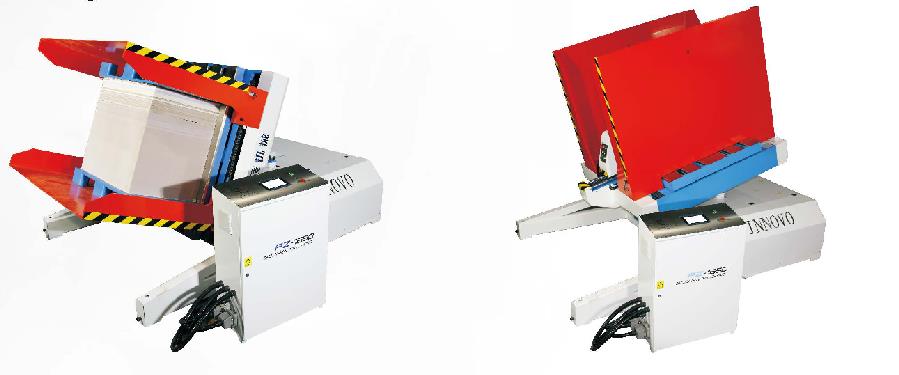

Working flow chart

1. Put the pile into platform of machine with hydraulic trolley.

2. Turning up, rotating and tilting.

3. Switch on the air jetting and vibration to remove duct(paper fiber, paper scraps)separate the sheets, aligning and turning paper pile.

4. The pile turner will come back to its original position, turn down. The pile can be take out by the hydraulic trolley.