QFM460&600 automatic book covering machine

| Price | $44.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Warranty:

1 Year

Type:

Other

Applicable Industries:

Printing Shops

Showroom Location:

None

Condition:

New

Application:

Machinery & Hardware

Packaging Type:

Cartons

Packaging Material:

Paper

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

380V

Power:

6.5kw

Place of Origin:

Anhui, China

Brand Name:

innovo

Weight:

2500kg

Dimension(L*W*H):

L8200XW2100XH1200mm

Key Selling Points:

Easy to Operate

After Warranty Service:

Video technical support, online support

Local Service Location:

None

After-sales Service Provided:

online support

Certification:

CE Certificate

Model:

QFM-460

Length of paper:

90-700MM

Width of paper:

170-450MM

Thickness of paper:

100-200g

Thickness of cardboard:

1-3mmplatform of cardboard feeding

Working speed:

7-30sheets/min.

Size of machine:

L8200XW2100XH1200mm

Needed heat:

4.5kw

Needed power:

6.5kw/380v

Weight of machine:

2500kg

Supply Ability

Supply Ability

100 Set/Sets per Month

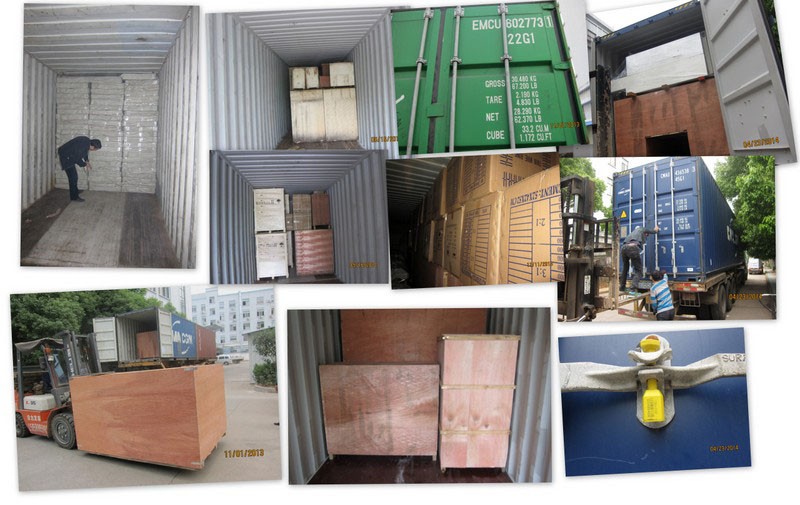

Packaging & delivery

Packaging Details

wooden case

Port

ningbo or shanghai port

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 30 To be negotiated

Product Description

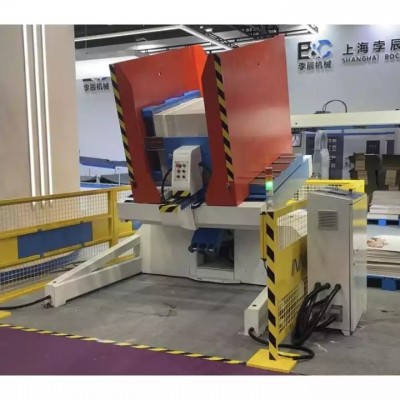

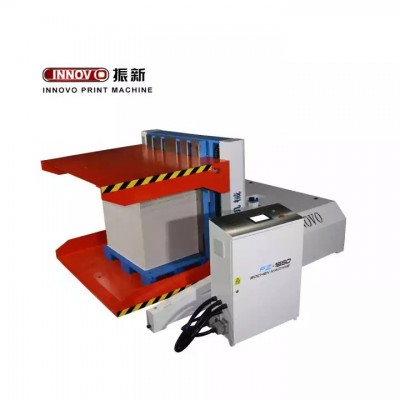

QFM460&600 automatic book covering machine

Specifications

1.automatic feeding,gluing

2.cardboard,positioning

3.folding,forming

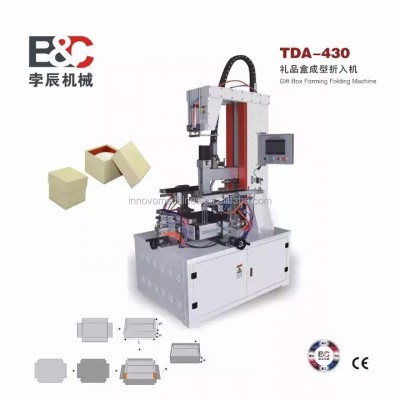

4finished products trimming, bindbook,calendar,etc.

QFM460&600 automatic book covering machine

Detailed Product Description

Characteristics:

1, This machine adopts automatic feeder paper feeding. Automatic gluing, automatic cardboard positioning, automatic folding and forming, automatic finished products trimming, and fast positioning. It is good for edition binding book cover, calendar, paper file, book-shaped box.

2, It adopts feeder back-pusher paper feeding structure, whole move servo and pneumatic control...

3, The unique cardboard positioning correcting function can locate the cardboard on the paper accurately and it can resolve the error caused by paper-surface deviation.

4, The production line suction device can avoid oatmeal paper curving and air bubble and the rear end equips automatic trimming device.

5, The finished products are neat and tidy, because it adopts the automatic controlling pulling yoke platform of collecting materials.

6,The machine adopts intelligent touch screen and operation, which ensures man-machine conversation more convenient and directly.

7,The machine equips Japanese OMRON PLC intelligent software control system, automatic error inspecting which ensures debugging more convenient and reduces the waste of raw materials.

Parameter:

Model | QFM-460 | QFM-600 |

Length of paper | 90-700MM | 90-700MM |

Width of paper | 170-450MM | 170-600MM |

Thickness of paper | 100-200g | 100-200g |

Thickness of cardboard | 1-3mmplatform of cardboard feeding | 1-3mmplatform of cardboard feeding |

Working speed | 7-30sheets/min. | 7-30sheets/min. |

Size of machine | L8200XW2100XH1200mm | L8200XW2250XH1200mm |

Needed heat | 4.5kw | 4.5kw |

Needed power | 6.5kw/380v | 6.5kw/380v |

Weight of machine | 2500kg | 2700kg |

QFM-600 total size :35m³

middle part:2.75x3.5x1.74m=16.7475m8

head :2.75x1.5x1.55m=6.39m³

wrapper :1.9x1.44x1.6m=4.378

corner:1.2x1.44x1.5m=2.59m³

receiving table :1.6x1.07x1.2m=2.05m³

electrical part:1.1x0.7x1.72m=1.32m³

pump:1.6x0.68x1.2m=1.3m³

Packaging & Shipping

1. The packing is confirm to export wooden case standard, strong and durable. The wooden case’s thickness is generally 1 cm.

2. In order to be waterproof, we usually use bubble film to wrap machine.

3. We can handle shipping for customers too.