FM720H Hydraulic Oil Heating Automatic Thermal Bopp Film Laminating Machine (Detachable)

| Price | $12.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Type:

Heated Roll Laminator

Paper Size:

280x200mm~690x580mm

Brand Name:

PRINTYOUNG

Model Number:

FM720H

Place of Origin:

Zhejiang, China

Max Paper Size:

690x580mm

Mini paper size:

280x200mm

Paper height:

450mm

Operating speed:

0-18m/min

Laminating temperature:

50-120℃

Total power:

4kw

Pressure:

3~8Mpa

Paper Thickness:

105-350g

Controller:

PLC

Dimensions(LxWxH ):

2.35x1.3x1.4m

Supply Ability

Supply Ability

30 Set/Sets per Month

Packaging & delivery

Lead time:

Quantity(sets) 1 - 10 >10 Lead time (days) 30 To be negotiated

FM720H Automatic Laminating Machine

Features

This is China's first self-developed paper feeding system.Our feeder has many patents.

What we are showing you now is model 720H.This model max paper width is 690 millimeter and max paper length is 580 millimeter.If you need a longer length,the length

can be customized.

All machines’ heating rollers of our company are equipped with oil heating system,which can solve the problem that Allover black,red and green and will not appear white spots.

Other companies are using electric heating in heating system.Electric heating will appear white spots.The pressure roller is made of Teflon material,which is non-stick and has a better laminating effect.The pressure adopts automatic hydraulic lifting function.and use frequency conversion speed control function,the fastest laminate speed can be about A3 paper 34 sheets in one minute.And our machine has Anti-curl function.Thinner paper after laminating will not curl.And with automatic overlap and automatic cut function.

Technical Parameters

Q1: Are you a manufacturer or a trading company?

A: Our shanghai office is mainly doing export. We have our own factory in Wenzhou, Zhejiang Province.

Q2. What is the machine warranty?

A: One year. After the warranty, we still provide technical support to buyer at low cost.

Q3. What is the production time while placing order?

A: Normally about 10-20 days.

Q4. What is the delivery time?

A: 15-30days after deposit.

Q5. Can your company handle shipping for customers?

A: Yes, just give us destination sea port or container yard.

Q6. Does the packing strong?

A: Yes. Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions. A full set of maintenance and operation manuals is included.

Q7. How about the machine installation and training ?

A: 1)We provide training in our factory for free; 2)We can send technicians (engineers) to your factory for installation and training. You shall pay the round trip air fare and accommodations, plus each technician charges USD100/per day.

Q8. Do you have machines in stock?

A: For standard model, we have a large quantity in stock. For special model, we need 20-30 days to produce it for you.

Q9. How can you assure the machines’ quality?

A: Each machine will be test running at least 24 hours before delivery to assure the quality. And during the warranty, we will give spare parts for free if machine has any problem.

Q10. Do you inspect machines or test running before packing?

A: Of course we do. We have QC department to debug the machine before packing. If you want to use specific material to do the test running, you need to pay for the cost of the material

Q11. What’s the payment term?

A: T/T 30% in advance, the balance shall be paid before delivery. We also accept payment by West Union or L/C at sight.

Q12. Do you accept factory visiting?

A: Warmly welcome for your visiting.

Q13. How many years are you in printing field?

A: Shanghai company is 12 years old, the factory is more than 20years.

Q14. How many clients do you have?

A: We have sold our machines to about 60 countries. We have agents in South Africa, Morocco and Italy.

Weight:

1500 KG, 1500kg

Warranty:

1 Year

Key Selling Points:

High-accuracy

UV lights:

1pcsx6.5Kw

IR lights:

6pcsx1.2Kw

Dimension:

5500x1180x1230mm

Package:

Wooden case

Max. Sheet Size:

720x1020mm

Maximum speed:

40m/min

Min. Sheet Size:

340*400 mm max paper size :700*1000mm

Carton Cube:

8m³

Sheet Weight:

127~400g/m2

Marketing Type:

Ordinary Product

Supply Ability

Supply Ability

20 Set/Sets per Month

Packaging & delivery

Packaging Details

wooden case

Port

Shang Hai

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 45 To be negotiated

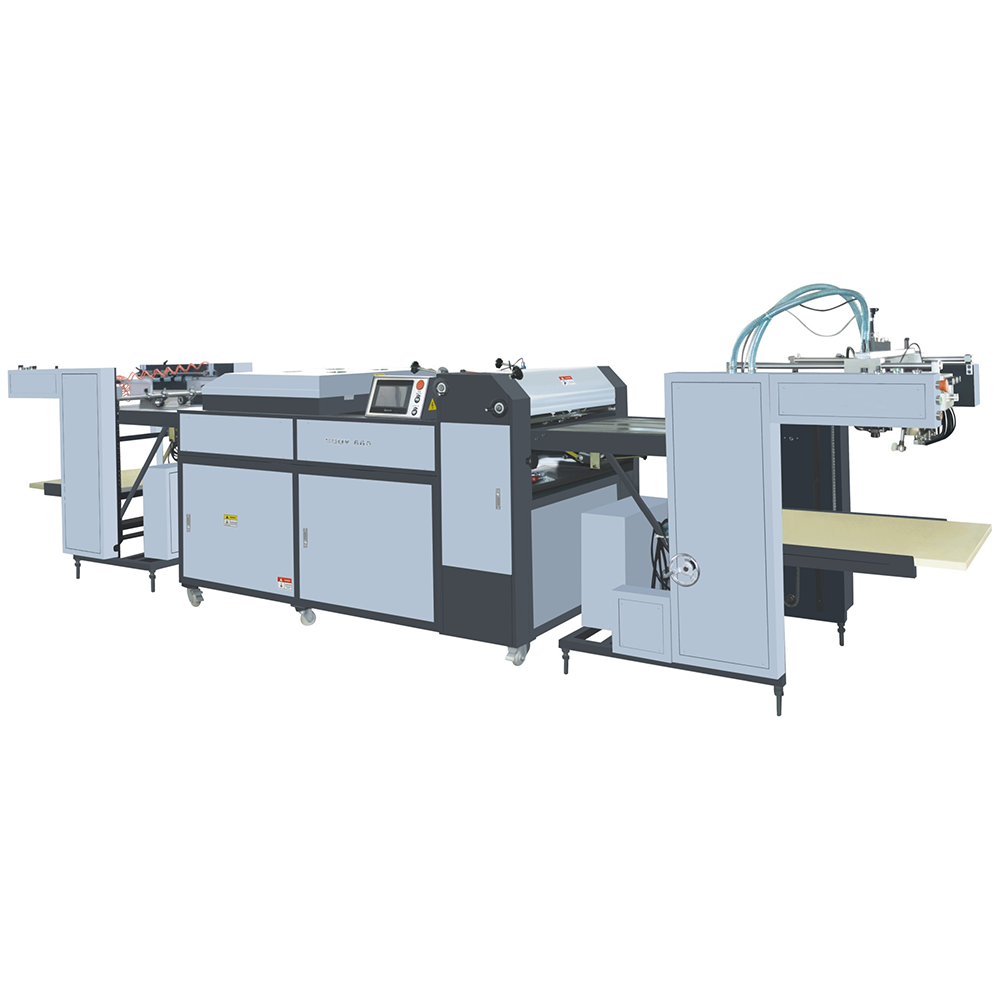

SGUV-740 Automatic Full UV Coating machine

Features

* With automatic feeder and the stacker.

* This UV Coating Machine is equipped with UV curing and IR drying device.

* Digital frequency converter speed control. And independent conveyor driven.

* Larger diameter coating rollers makes the coating effect smoother & brighter.

* Full coverage splash guards to protect from splashing.

* Used vacuum airbed for maximum hold down the paper sheets on conveying.

* UV magnetic leakage transformer with parallel capacitor design can better endure the voltage fluctuating impact.

* Two level UV lamp power setting.

* Easy access UV lamp chamber and replacement.

* High velocity blower fan for cooling and exhaust.

* Safety locker on all machine doors and covers.

* Full coverage protection against UV radiation around the UV lamp chamber.

* Lower temperature control on the UV lamp chamber surface.

* Emergency stop switches at arms length throughout the machine.

* Interlocks design prevents against mis-operation.

Technical Parameters