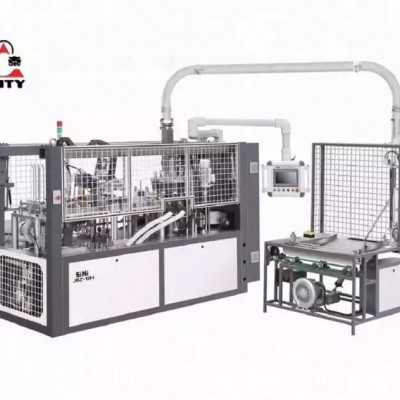

high speed paper cup forming machine

| Price | $35.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Condition:

New

Product Type:

Paper Cup Machine

Processing Type:

Paper container forming

Place of Origin:

Zhejiang, China

Brand Name:

WITY

Voltage:

380v/3P/50Hz

Power:

7.5kw

Dimension(L*W*H):

740x400x1700mm and 1150x650x2000mm

Weight:

3500kg

Warranty:

1 year

Certification:

ce

After-sales Service Provided:

Engineers available to service machinery overseas

speed:

65-85pcs/min

color:

grey and white

Cup size:

6-12oz

Top diameter:

60mm-110mm

Bottom diameter:

50-70mm

Cup height:

50-135mm

bottom deep:

5-10mm

raw material:

One side/double size PE coated

paper thickness:

190gsm~350gsm

Supply Ability

Supply Ability

5 Set/Sets per Month

Packaging & delivery

Packaging Details

Export wooden package

Port

Shanghai or Ningbo

High speed paper cup forming machine, paper bowl making machine, paper cup forming machine, paper bowl machine, paper cup making machine

1. Description:

JBZ-H High Speed Paper Cup Forming Machine is a high speed automatic machine with multi-working station.

It products single and double side PE paper cup through the procedure of automatic paper feeding,

sealing, silicon oil lubrication, bottom punching, heating knurling, curling and cup can be of for beverage, ice cream etc.

This machine has adopted new technology, such as multi-working station rotary mould head,

2. Feature:

a.with advance open type indexing cam structure, high precision making, insure the machine stable running

b. With imported non-flame heating system, reliability and improve the productivity.

c. Encircling type steel structure, compact and stable frame.

d. All the parts and components are standardized production, easy for machine maintenance.

e. Adopt automatic closed lubrication system ensure the machine long period non-stop working at high speed

f. Intelligent design, PLC automatic control, with servo motor drive,

automatic defective alarming, counting, and stop, etc

3. Main Specification:

Cup size | 6~12oz(outside diameter of top: Ø 60mm~ Ø110mm, bottom:Ø50mm~ Ø70mm, height: 50~135mm, depth of bottom: 5~10mm ) |

Rated speed | 65-85pcs/min |

Main motor power | 2.2kw |

Electro thermal power | 8.6/13.2kw |

Actual power consumption | 7.5kw |

Air source | 0.8 m3/min :0.6Mpa |

Applicable base paper | 190~350g/ m2(single or double PE coating paper ) |

Weight | 3500kg |

Packing dimension | 740x400x1700mm and 1150x650x2000mm |

Remark | The paper thickness error margin is ±0.05mm for the same set of mould |

Oil spindle lubrication system and integrated steel structure frame |

4. Function list

1 | Automatic paper detaching for paper sucking station |

2 | Automatic alarming while material paper lack |

3 | Multiple paper (no paper sucking or paper blocking) detection and stop system |

4 | Automatic paper tracking and bottom paper feeding |

5 | Monitoring and auto-stop in case of no paper during sealing procedure |

6 | Ultrasonic probe detection system, o sonic while no paper |

7 | Monitoring and auto-stop in case of no cup tube during sealing procedure |

8 | Cup tube fetching device with detector for bottom paper automatic feeding |

9 | Detect and stop while servo transmitting no bottom paper, oblique bottom paper |

10 | Cup drop off detection and stop |

11 | Cup over pass detection and stop |

12 | Cup on 18 station of machine can be set to separation |

13 | The machine won’t start if the bottom forming has not reach the setting temperature |

14 | If the machine doesn’t work for 5 minutes, it will turn to energy saving mode automatically |

15 | The cup collecting device with manual cup holding, discharge function |

16 | PLC control system can set the automatic stop of paper collection while no paper cup coming out |

17 | The encoder control angle can be adjust at random |

18 | High position stop function (equipments can be separated automatically after stop-running) |