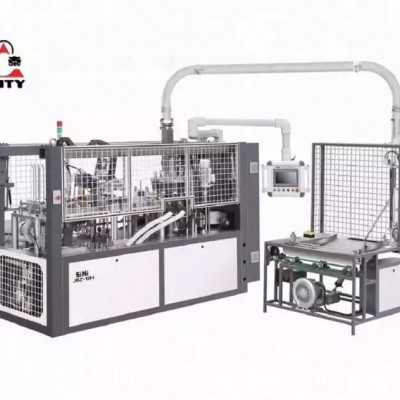

JY-120B Paper Tube Making Machine

| Price | $11.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory

Showroom Location:

Turkey, Viet Nam, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Spain, UAE, Colombia, Algeria, Sri Lanka, South Africa, Ukraine, Uzbekistan, Malaysia

Condition:

New

Product Type:

paper tube making machine

Processing Type:

paper

Place of Origin:

Zhejiang, China

Brand Name:

WITY

Voltage:

380V 50HZ

Power:

7.5kw

Dimension(L*W*H):

3600x2000x1800mm

Weight:

2000kg

Warranty:

1 Year

Production Capacity:

Winding 3-20m/min

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Marketing Type:

Ordinary Product

Warranty of core components:

1 Year

Core Components:

PLC, Motor, Pump, Gearbox

After-sales Service Provided:

Engineers available to service machinery overseas, Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, online support

Number of roller:

2-16 layers

Tube diameter:

20-200 mm

Tube wall-thickness:

1-10 mm

Core mould fixed way:

Three claws chuck

winding head:

4

Cutting way:

Round knife

Gluing way:

Double sides

After Warranty Service:

Video technical support, online support, Spare parts, Field maintenance and repair service

Local Service Location:

Turkey, Viet Nam, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Spain, Malaysia, Morocco, UAE, Algeria, South Africa, Ukraine, Uzbekistan

Certification:

Other

Supply Ability

Supply Ability

20 Set/Sets per Month

Packaging & delivery

Packaging Details

standard wooden package

Port

Ningbo or Shanghai

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 30 To be negotiated

Video Description

Product Description

Used in paper industry and all kinds of thick tube production. Such as , roll paper core, BOPP film inner core and industrial pipe ,etc

Feature

1.Low price, strong practicability, stable performance;

2.Automatically cut, automatically fall pipe, automatically change speed and revert;

3.Computer PLC control, touch screen man-machine interface operation;

4.Round knife cutting, incision more smooth, performance more stable;

5.Stainless steel gluing box, with polyurethane scraper and high carbon steel plastic knife, durable in use;

6.Automatically gluing system

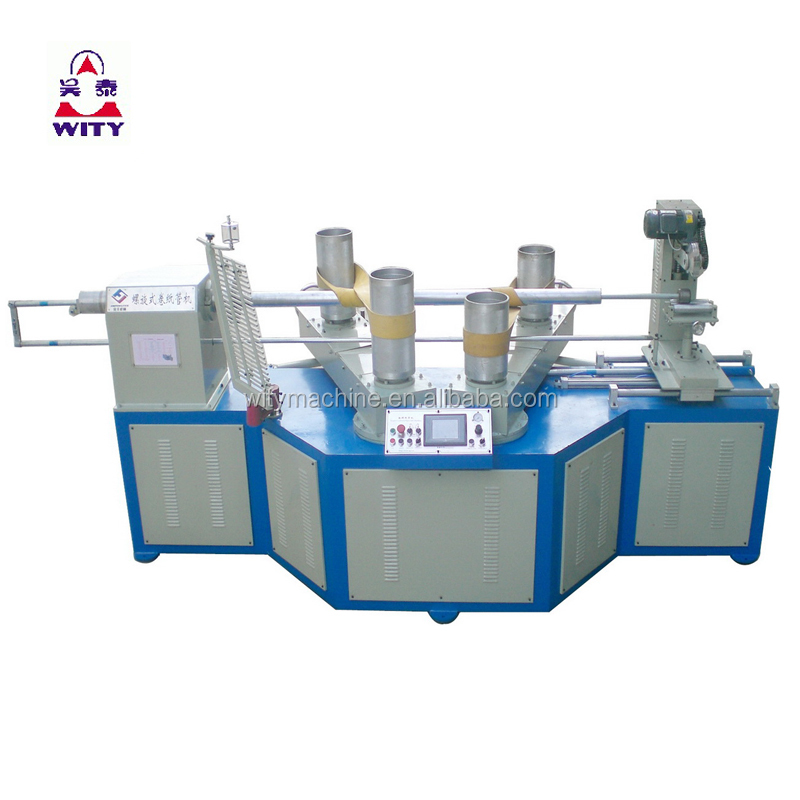

Main specification

Machine photos

Paper Rolls Shelf

Gluing System

Paper Tube Holding Shelf