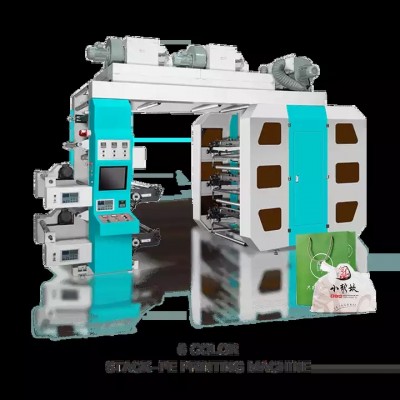

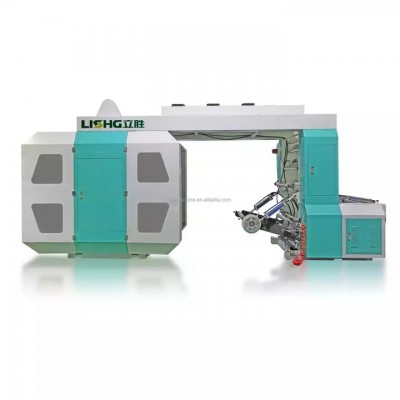

Six color shrink film BOPP PE central impression flexographic printing press

| Price | $76.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Type:

Flexographic Printer

Applicable Industries:

Manufacturing Plant, Printing Shops

Condition:

New

Plate Type:

Letterpress

Place of Origin:

Zhejiang, China

Brand Name:

lisheng

Usage:

Paper Printer, plastic film

Automatic Grade:

Automatic

Color & Page:

Multicolor

Voltage:

380v

Dimensions(L*W*H):

7200*2320*4820mm

Weight:

6000 KG

Print Dimension:

1300mm

Print Speed:

150m/min

Warranty:

1 Year

Key Selling Points:

Long Service Life

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Bearing, Motor, Pump, Gear, PLC

Structure:

CI

Printing material:

Film

Application:

Flexible Package Printing

Machine Type:

Central Impression

function:

plastic bag printing machine

Printing Width:

300-1300mm

Anilox roller:

Ceramic Anilox Roller

Tension:

Auto Tension Controller

Ink:

Solvent Ink And Solvent Ink

Speed:

150m/min

Product:

plastic bag printing machine

Supply Ability

Supply Ability

20 Set/Sets per Month or more

Packaging & delivery

Packaging Details

Film package, printing unit with wodden box

Port

Ningbo

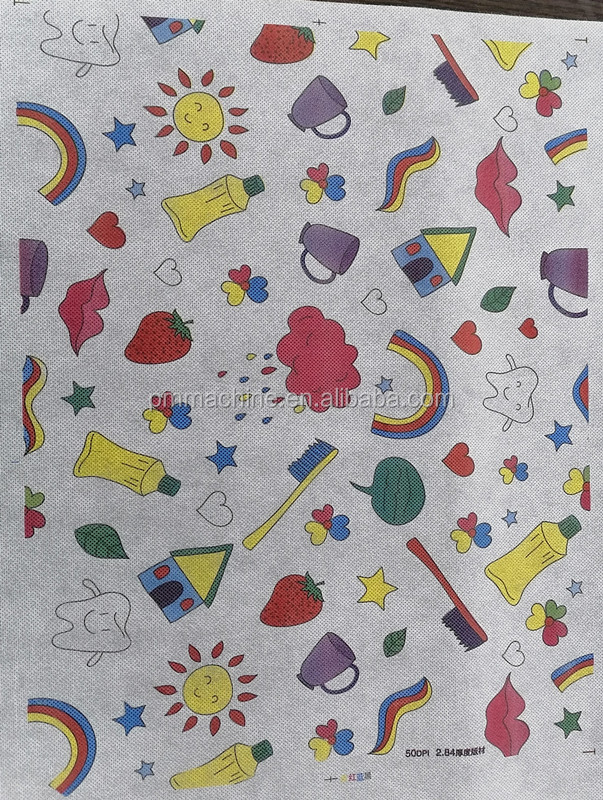

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 70 To be negotiated

Video Description

Product Description

This central impression (central drum)flexographic printing machine is suitable for printing such packing materials as

paper material between 20--200gsm.And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

Main Features

1) Central impression type printing machine with better color registration. Due to the big drum, the printed material is

supported by the big drum, and greatly improving color registration, especially with extensible materials.

2) All colors printing station drived by the central drum, Less transmission errors because of less gear transmission, increase the registration precision.

3) Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

4) The machine is equipped with blower and heater; and the heater employed central temperature control system,

automatic temperature controller, and separated heat source.

5) The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6) Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7)Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance,

beating small, achieves finally perfect printing effect.

8)Accurate printing effect achieved by special gear transmission device.

9)The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

Sample pictures