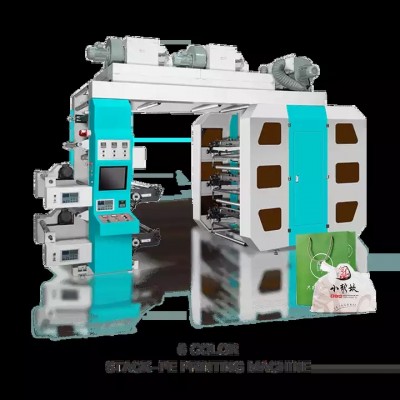

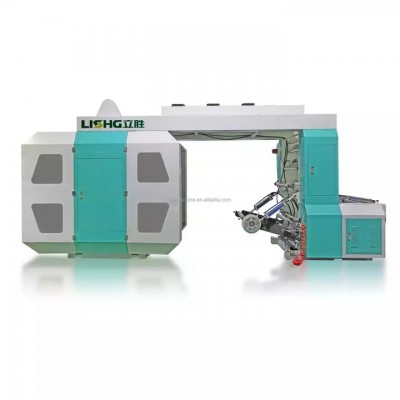

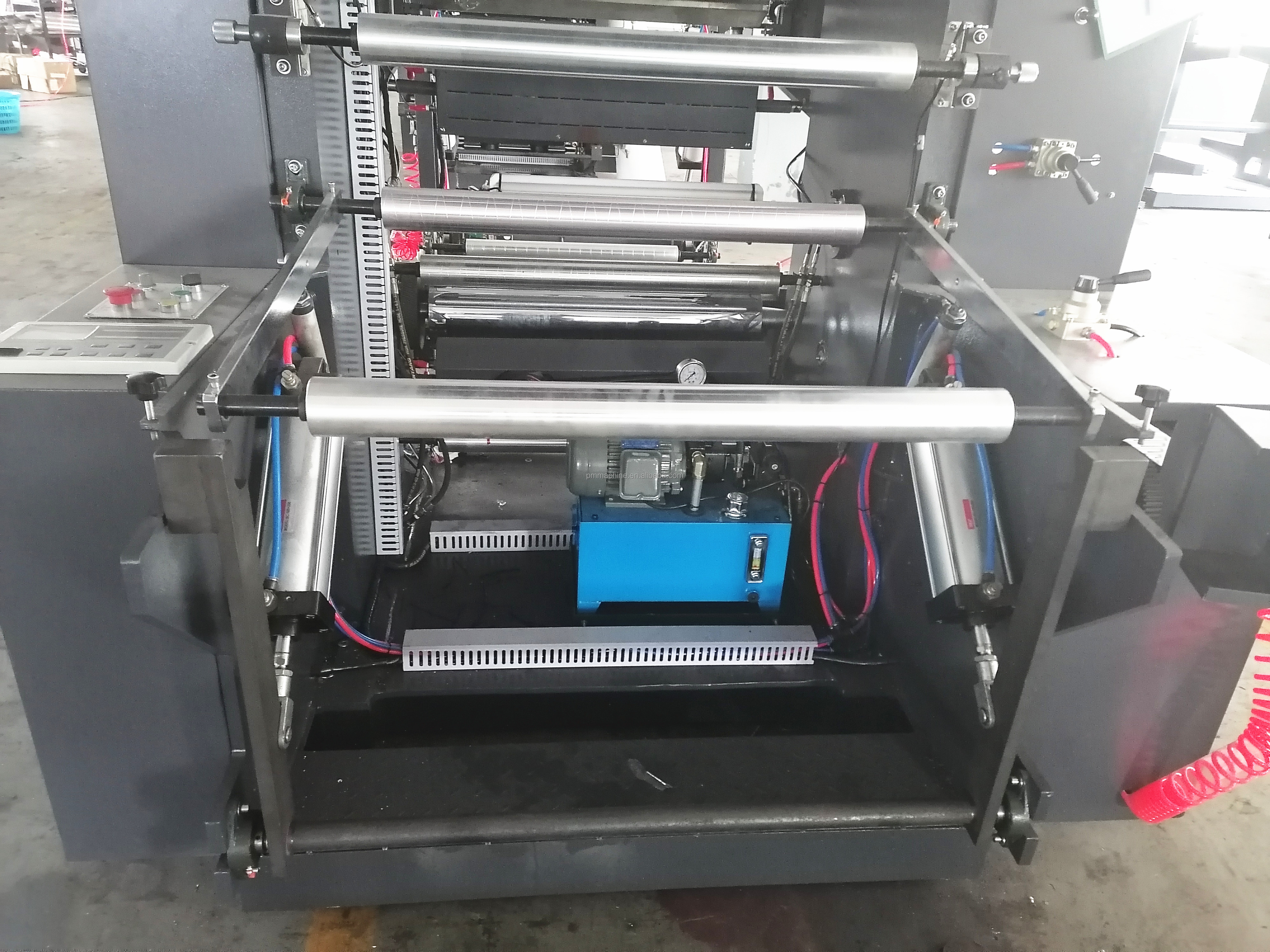

4 color polythene bag pp woven sack flexo paper food wrapped printing machine roll to roll flexograp

| Price | $12.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Type:

Flexographic Printer

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory, Printing Shops, Packaging

Condition:

New

Plate Type:

Letterpress

Place of Origin:

Zhejiang, China

Brand Name:

Lisheng

Usage:

Paper Printer, Label Printer, Bill Printer, Plastic Bag, Non Woven Bag, Paper Bag, paper roll/PP woven

Automatic Grade:

Semi-automatic

Color & Page:

Multicolor

Voltage:

220v 380v

Dimensions(L*W*H):

customized

Weight:

5000 KG

Print Dimension:

191~1000

Print Speed:

100m/min

Warranty:

1 Year

Key Selling Points:

Multi Color

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Bearing, Motor, Pump, Gear, Other

Structure:

Stack

After-sales Service Provided:

Engineers available to service machinery overseas

Suitable material:

paper, plastic film, non-woven, pp woven roll so on

Gurantee:

One year for free, Long life service

Operating Way:

Helical gear

Printing speed:

10~80m/min

Main motor power:

3.7kw

Register precision:

within 0.25mm

Anilox roller:

Ceramic Anilox Roller

Max. oven temp.:

Max. 80℃(room temp. 20℃)

Gear module:

1.5mm

Supply Ability

Supply Ability

25 Set/Sets per Month Plastic Film printing machine

Packaging & delivery

Packaging Details

Stretch Film for Plastic Film printing machine or Wodern box packaging according to customer's requests

Port

Ningbo

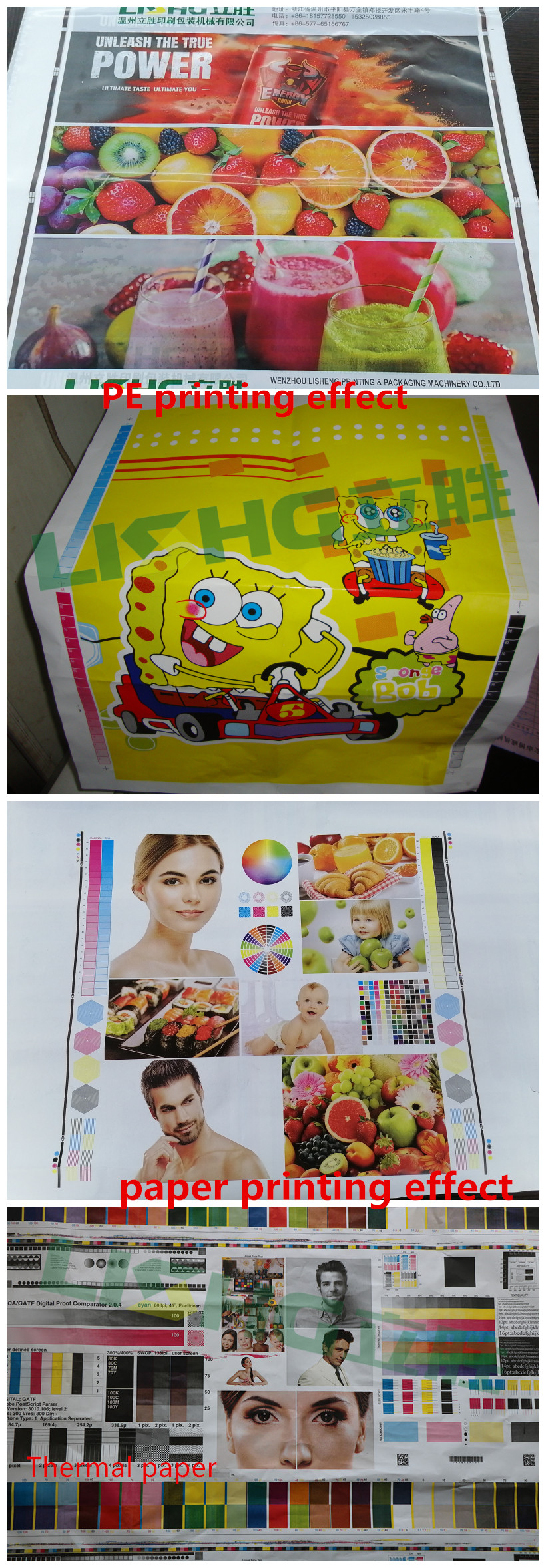

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 35 To be negotiated

Video Description

Product Description

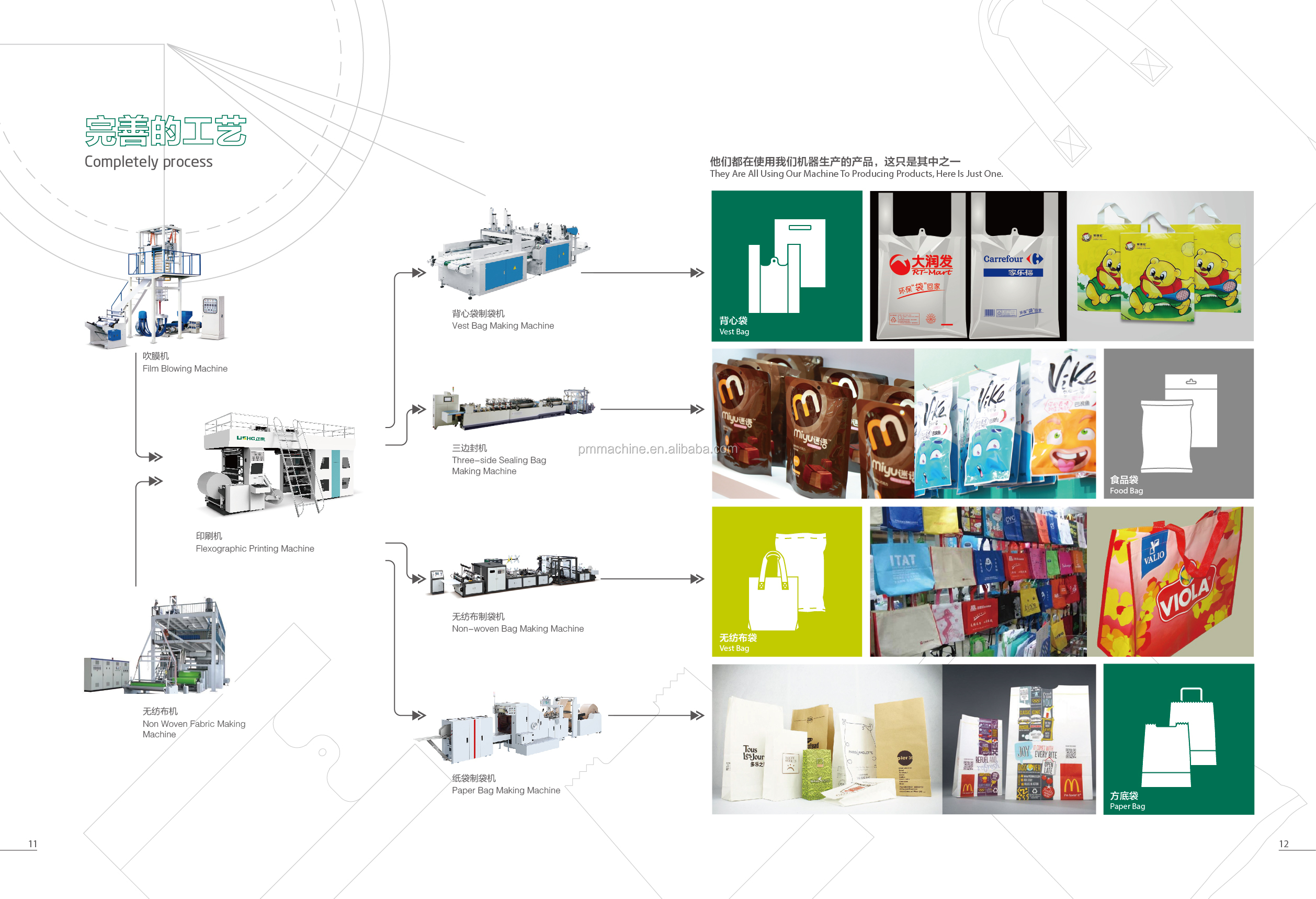

Flexographic printing machine is suitable for printing such packing materials as PE, PP bag, cellophane and roll paper, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Characteristics:

1.Easy operation, flexible starting, accurate color register. 2.The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off. 3.Manual printing cylinder lift and lower, it will stir the printing ink automatically after lifting. 4.The printing ink is spread by the anilox cylinder with even ink color. 5.Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops. 6.360°continuous and adjustable longitudinal register device. 7.The frequency control of motor speed adapts to different printing speeds. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

Sample effect pictures