HCM Auto preheat and turn off roll to roll fabric printing machine

| Price | $9.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Type:

Heat Transfer, roller sublimation heat press machine

Condition:

New

Plate Type:

roller sublimation heat press machine

Place of Origin:

Guangdong, China

Brand Name:

HCM

Model Number:

HCM-F4217T

Usage:

Cloths Printer, garment,textile,t shirt,roller and piece material

Automatic Grade:

Automatic

Color & Page:

Multicolor

Voltage:

220V/380V

Gross Power:

18KW

Dimensions(L*W*H):

3.9*2.64*1.26m

Weight:

1000KG

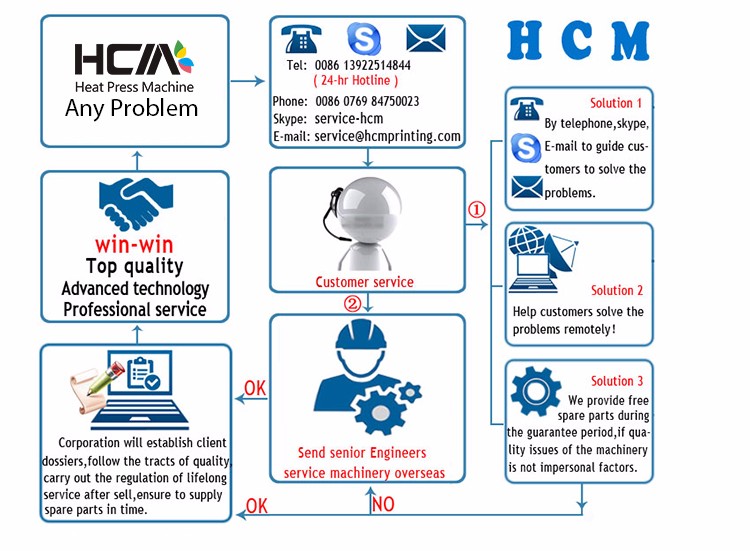

After-sales Service Provided:

Engineers available to service machinery overseas

Roller width:

1.7m

Roller diameter:

420mm other can be designed as your requirement

Temperature range:

0-399°C

Printing temperature range:

0-240°C

Printing speed:

0-6m/min (420mm diameter)

Machine color:

blue,red,silvery and so on

Heating style:

heating oil

Pressure:

0-8kg/cm with pressure strengthen system

Warranty:

1 year for Best big size rotary heat press machine for sheet

Certification:

CE

Supply Ability

Supply Ability

50 Set/Sets per Month

Packaging & delivery

Product Overviews

Touch screen panel digital sublimation printing rotary heat press machine

HCM-F4217T

Product Feature

1. Roller surface with Teflon coat, high hardness,wear resistant,anti-sticking

2. Digital temperature and speed hardness,wear resistant,anti-sticking

3. Oil heating,temperature uniformity (±1-2°C) no deviations of color.

4. Using imported heating pipes,heat evenly,durable;imported blankets which is not easy to deviate.

5. The blanket is detachable,and not easy to burn;with belts putting device for installing and fixing the belts.

6. Without smoke and abnormal odour during working.

1.control panel 2.roller 3.conveyor belt 4. feeding fabric pole 5.electricity box

6.working table 7.Printing paper rewinding 8.Putting printing paper

![]()

Product Effects

Product Feature

1. Roller surface with Teflon coat, high hardness,wear resistant,anti-sticking

2. Digital temperature and speed hardness,wear resistant,anti-sticking

3. Oil heating,temperature uniformity (±1-2°C) no deviations of color.

4. Using imported heating pipes,heat evenly,durable;imported blankets which is not easy to deviate.

5. The blanket is detachable,and not easy to burn;with belts putting device for installing and fixing the belts.

6. Without smoke and abnormal odour during working.

Use the computer to devise the designed pattern,print it on the specific transfer paper through digital

printer by using sublimated ink,and then become transfer printing paper.

Let the transfer paper which has design cling to the fabric and feed together into the roller heat printing

machine.Through high temperature and high pressure,sublimation ink on the transfer paper will transfer to

fabric by pneumatolysis,printing is completed and tailor the printed fabric to become clothes.

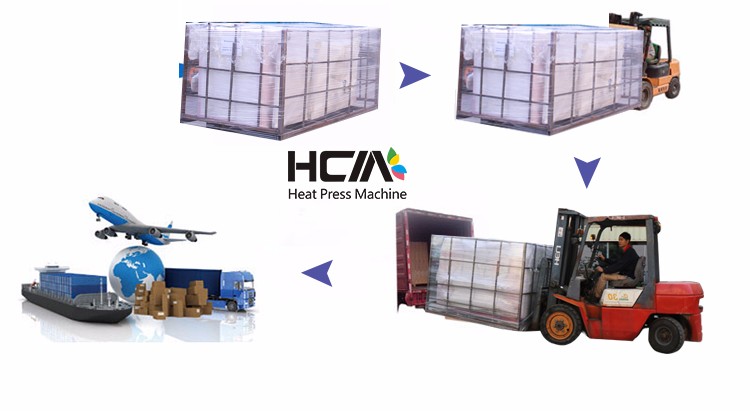

Packaging

Packing Details:

High speed digital sublimation printing rotary heat press machine packing will be made according to customers’ requirements.

Here is safe packing method as below:

Machine will have PVC bag and foam inside ,iron frame outside.

Iron frame is used for all parts of the machine together and protect the macine.

![]()

1.Technical support of the digital heat printing machine are available for ever

2.Technical support of fabric printing&printer are available for ever

3.Operation description&attention matters are available for ever

4.Operation videos of the machine is available for ever

5.Engineers available to service machinery overseas

6.Free apare parts available(one temperature controller,one set of carbon brush,one group of heating pipes)

7.Help customers to find paper,ink,protecting paper,and any other printing material freely

8.Fabric and ribbon heat printing business available