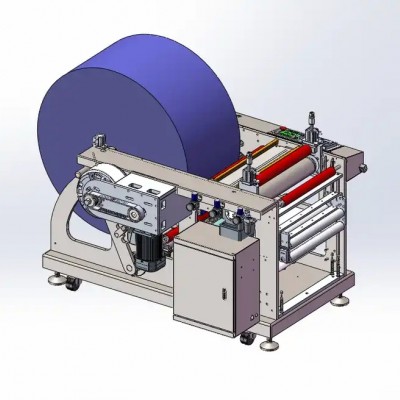

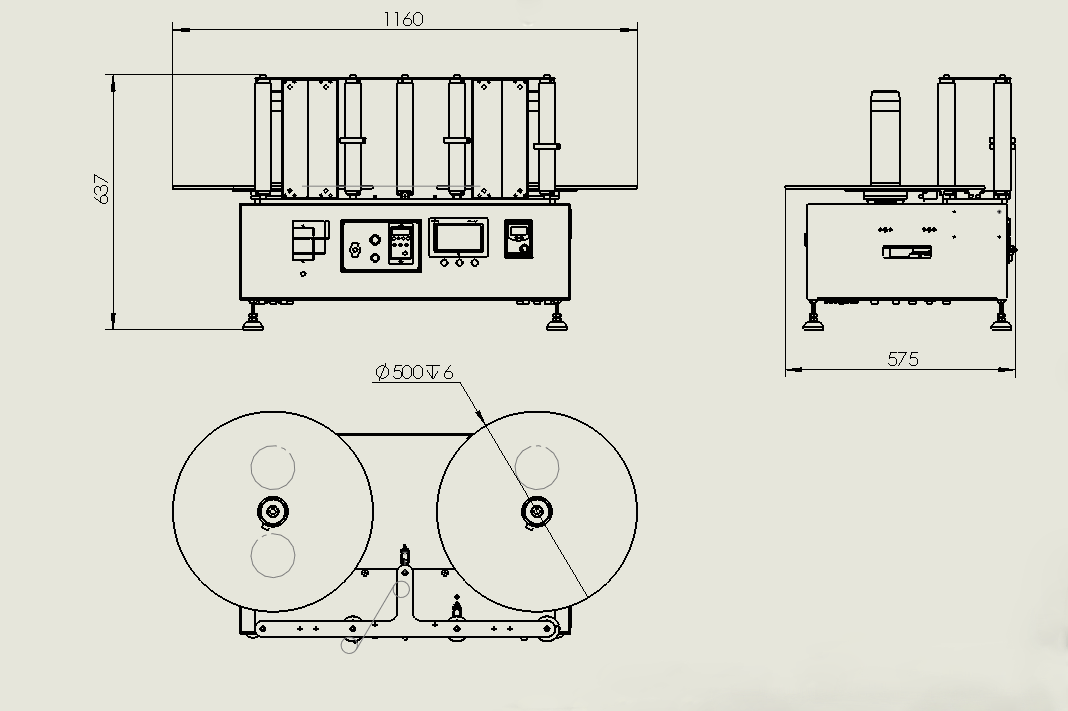

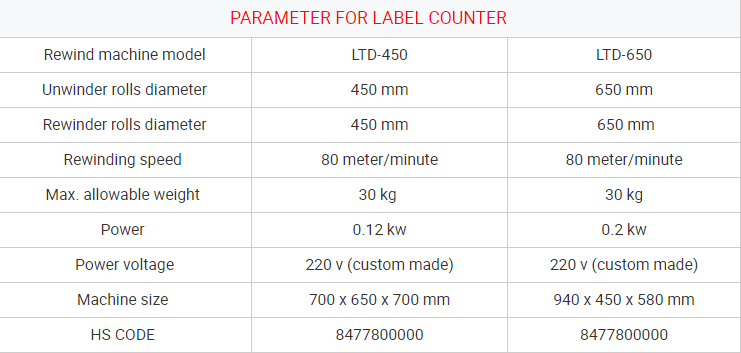

Wind and Rewind Machine from Roll to Roll with Multi-functions

| Price | $1.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Applicable Industries:

Manufacturing Plant, Printing Shops, Other, Advertising Company

Showroom Location:

Viet Nam, Russia

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

Ordinary Product

Warranty of core components:

1 Year

Core Components:

Motor, Gear

Condition:

New

Automatic Grade:

Automatic

Place of Origin:

Fujian, China

Brand Name:

Lingtie

Voltage:

220v

Weight:

70 KG

Warranty:

1 Year

Key Selling Points:

Easy to Operate

After-sales Service Provided:

Engineers available to service machinery overseas

Keyword:

label roll rewinding machine

Function:

rewinding

feature:

OEM

Rewinding speed:

40-120 meter / minute

After Warranty Service:

Video technical support

Packaging & delivery

Packaging Details

the wooden box with foam

Picture Example:

Lead time:

Quantity(units) 1 - 1 2 - 5 >5 Lead time (days) 15 20 To be negotiated

Product Description

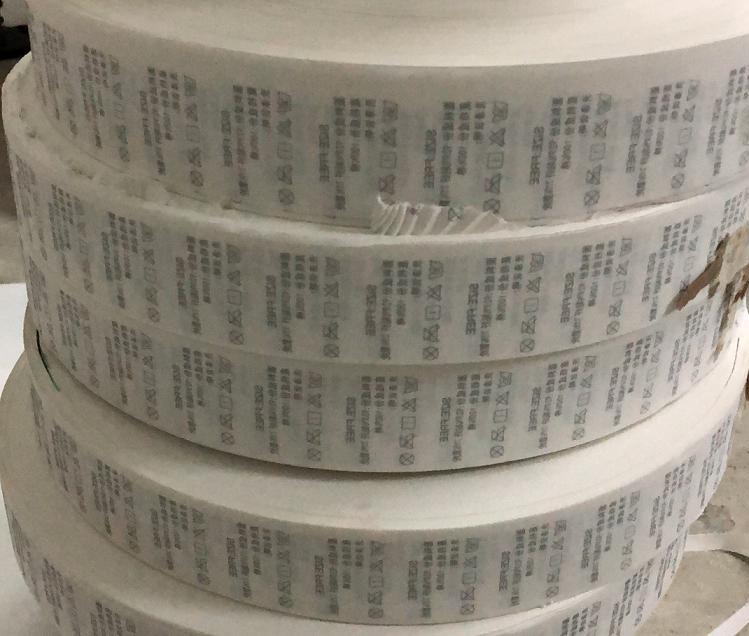

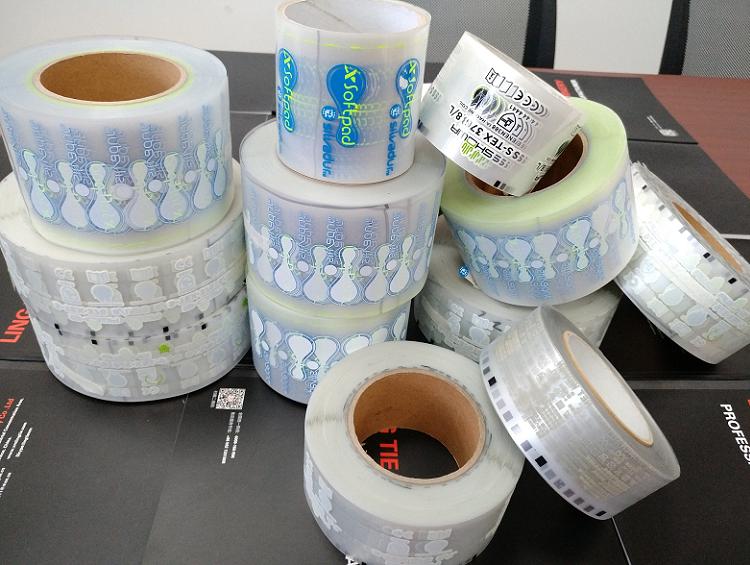

1) The machine can rewind many kinds of plastic films , such as PVC , PC ,PET , PE , PP film.

2) This Label Counters are a quick and easy way to count the number of labels in roll.

3) take a large roll of labels and make several small rolls out of it. The counter modules have a 6 digit LED read-out for easy reading and allow you to count up or stop at a preset count.

Main Features description of the Rewinding Machine

1) PLC display screen is optional. 2) Good motor to keep the stepless speed changing and stable operation.

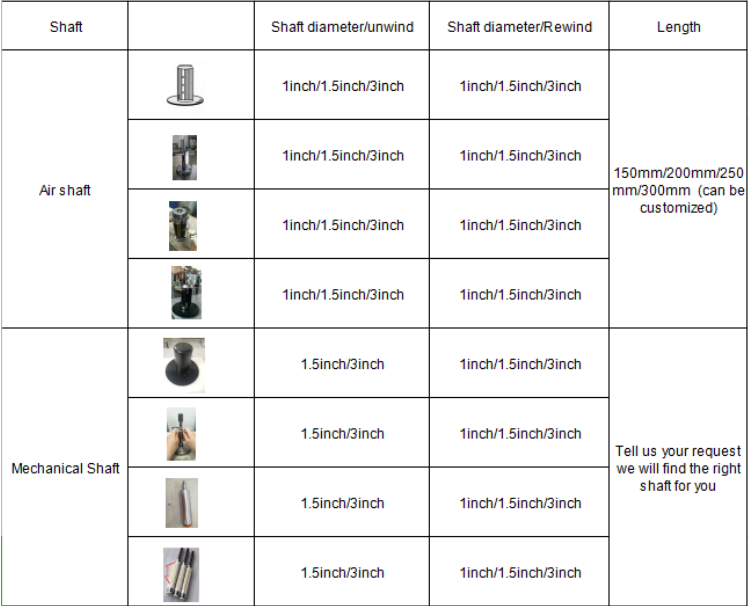

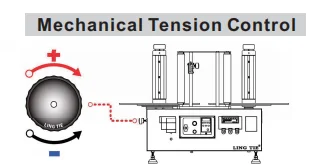

3) Unwinding shaft & rewinding shaft size can be customized. 4) Air shaft and Mechanical shaft type can be choose. 5) Magnetic powder tension controller is optional.

Detailed Images

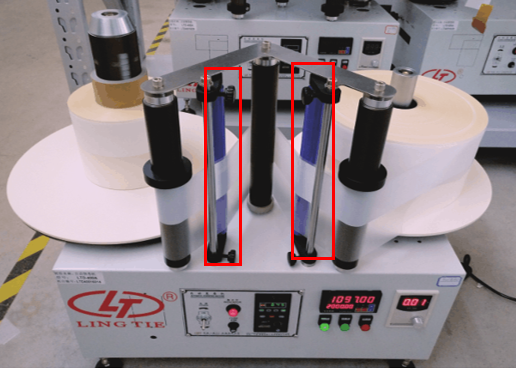

Multi-function for Option

Counting sensor

The length of the roll material is calculated when rewinding with almost zero error.

Meter sensor

The number of the roll material is calculated when rewinding with almost zero error.

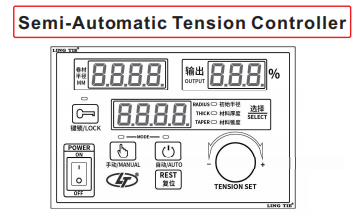

Tension controller

Tighten the roll material to prevent the uneven winding of the roll material.

Deviation correct function

Make the uneven material become to smooth surface.

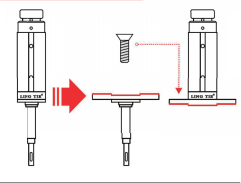

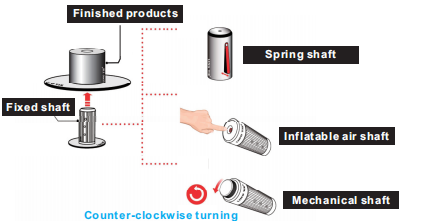

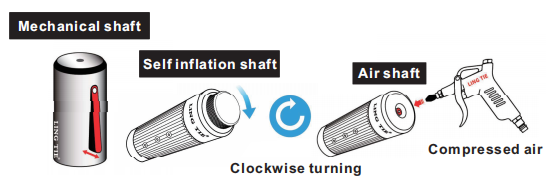

Interchangerable shafet

Different types of shafts can be selected according to the diameter of the roll materials to achieve the maximum utilization of the machine

Splice station

Make the two rolls of material more evenly spliced together.

Static elimination brush

Effectively remove static electricity from the material surface.

Dust elimination roller

Remove dust from materials.

Optional shafts

Selection of Tension Control

Best Selling

view more >>Recommended by seller

Label Roll Rewinding Machine

$1,300.00 - $3,200.00 / unit

1.0 unit

Label Rewinder with Counter Rewinding Machine

$900.00 - $1,200.00 / set

1 set

Roll to Roll Multi Color Screen Printing Machine

$40,000.00 - $50,000.00 / set

1.0 set

Automatic Roll to Roll CCD Alignment Screen Printing Machine for Touch Screen FPC RFID

$35,000.00 - $57,000.00 / set

1.0 set

Automatic Slitter Rewinding machine for Plastic Film Paper in Roll

$5,000.00 - $7,000.00 / set

1.0 set

Reel to Reel Label Counter Rewinder Machine

$1,250.00 - $1,400.00 / unit

1 unit

IMD IML Screen Printing Machine

$32,000.00 - $62,000.00 / set

1.0 set

Automatic web guide & rewinding machine

$4,800.00 - $5,000.00 / set

1.0 set

Automatic Rewinding Machine with Web Guide

$4,500.00 - $4,600.00 / set

1 set

Rewinding Machine with edge control for Material in roll

$4,300.00 / set

1 set

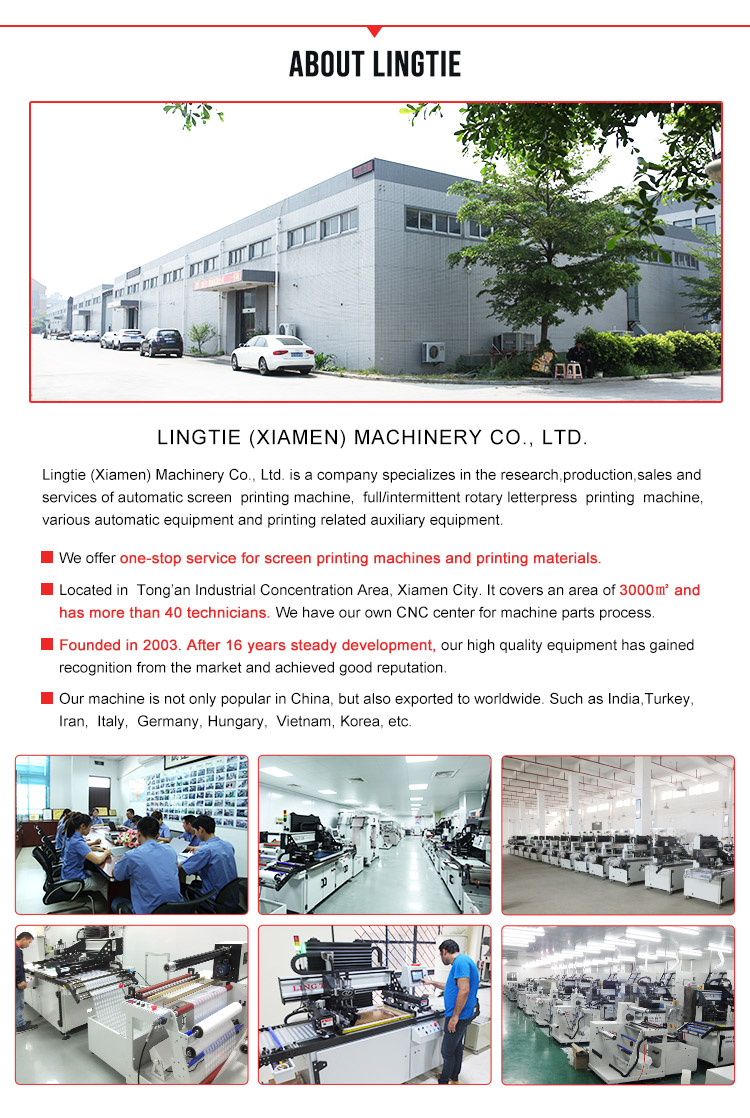

Company Introduction