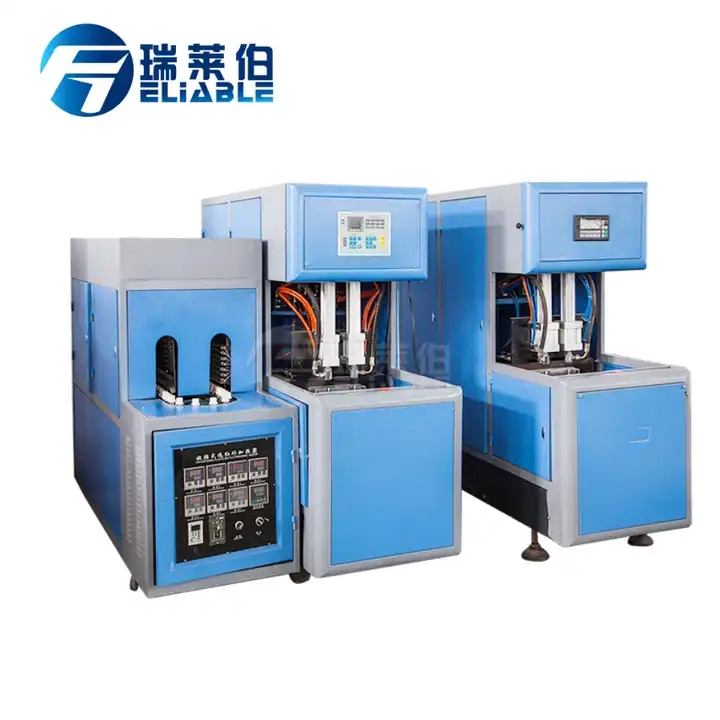

Semi automatic mineral water stretch blow 1cavities or 2 cavities 2000BPH PET plastic bottle molding

| Price | $8.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Condition:

New

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty of core components:

2 years

Core Components:

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Plastic Processed:

PP, PC, PVC, PET

Place of Origin:

Jiangsu, China

Brand Name:

Reliable

Year:

2023

Voltage:

380V/3PH/50HZ or by order

Clamping Force (kN):

2200

Screw diameter (mm):

3700 mm

Output (kg/h):

20 kg/h

Automation:

Semi-automatic

Screw Heating Power(kW):

78 kW

Extruder Motor Power(kW):

72 kW

Mold Platen Size(Width)(mm):

3125 mm

Mold Platen Size(Height)(mm):

2150 mm

Air Pressure(MPa):

9 MPa

Air Comsumption(m³/min):

30 m³/min

Die Head Heating Power(kW):

72 kW

Accumulator Capacity(L):

6000 L

Power (kW):

30

Weight (T):

4.5

Key Selling Points:

Easy to Operate

Warranty:

2 years

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory, Food Shop, Food & Beverage Shops

Showroom Location:

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia

Packing type:

Cartons+ Wooden Packaging

Product name:

Automatic Plastic Water / Beverage Bottle Blowing Making Machine

Name:

Bottle Automatic Blow Molding Machine

Key words:

Automatic Extrusion Blow Moulding Machine

Suitable bottle:

Drink Bottle

Color:

Blue

Material:

SUS304/316

Capacity:

2000bph

Keywords:

Moulding Machine

Supply Ability

Supply Ability

3 Set/Sets per Month water fliingmachine mineral water bottling machine

Packaging & delivery

Packaging Details

Export wooden case

Port

Shanghai Port

Picture Example:

Lead time:

Quantity(sets) 1 - 1 2 - 2 >2 Lead time (days) 30 45 To be negotiated

about Reliable Machinery

Zhangjiagang Reliable Machinery Co., Ltd. is one of the most credible and international solution provider which integrates designing, producing, marketing and offering the turn-key project of liquid filling and packing line. based on 15 years of research, experience and advanced technology absorbed from Europe and America, Reliable has become the industry leading manufacture and deeply appreciated by many major brands all over the world.

Product Features

Brief introduction

Semi automatic bottle blow molding machine is suitable for producing PET plastic containers and bottles. It is widely used to produce the carbonated bottle ,mineral water,carbonated drink bottle, pesticide bottle oil bottle cosmetics,wide-mouth bottle etc. Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,the perform rotated and heated equally.

1. Produce bottle from 0.2L to 2L. 2. Output capacity: 2000bph- 0.5L, 4-cavities blow mold. 3. New version in 1 heater oven and 1 blower, the area of machine settlement is reduced. easier operation for operator, no need too much movement. 4. Advanced PLC control system with a use-friendly panel and time-control precision of PLC, up to 0.01second,Double start working buttons, which is designed for avoiding the injury. 6. Independent Temperature Control for different heating lamp to get ideal preform heating. 7. Heating lamps are adjustable in directions to suit various preforms. 8. One Operator needed and no need extra training. 9. Simple installation & startup adjustment. 10. Energy Saving--low investment--easy to operate and safety. 11.The machine frame is produced by the whole complete casting bottom, so that the machine is firm and running stable. 12.The stretching air cylinder is adjusted parallel from front to back, from left to right freely by regulator.

Selection For Capacity

Semi Automatic 1 Cavity

Blow Molding Machine

Suitable Bottle : 3-10L / 5 Galon

Semi Automatic 2 Cavity

Blow Molding Machine

Suitable Bottle : 200-2000ML

MORE DETAILS

Technical Data

MOULD & BOTTLE SHOW

Principle Display

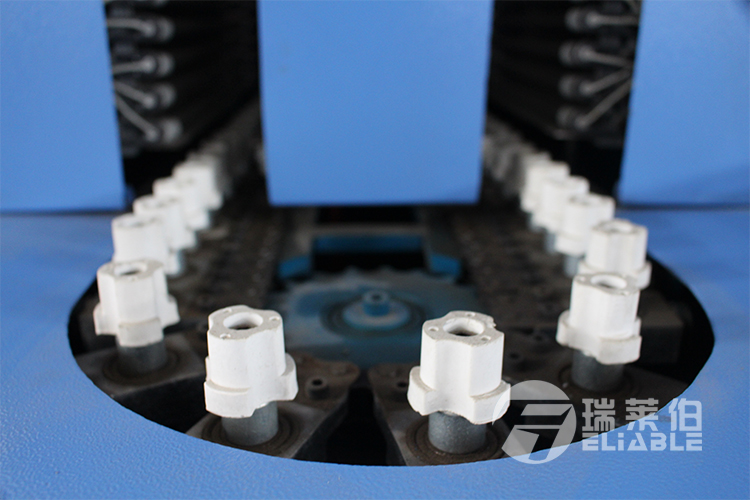

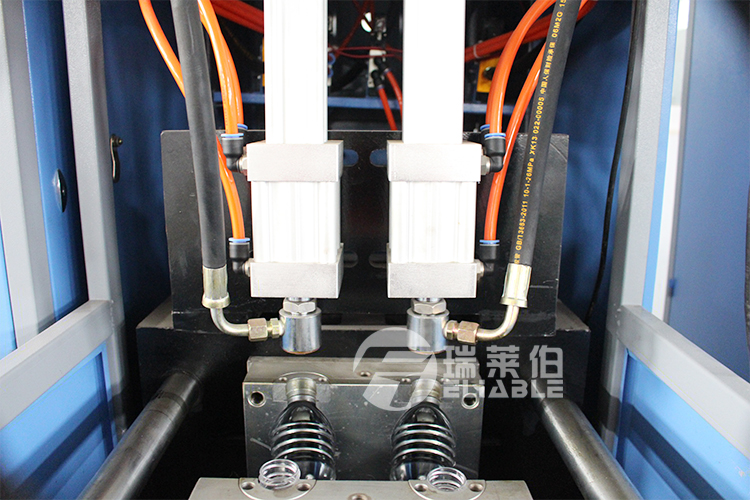

Key Part You Care about The Most

Heater Part

1 - Adopt special electronic controlling circuit for heating, high efficiency in simultaneous controlling.

2 - one lamp or more, lower power consumption.

3 - The preform will be heated evenly, not be influenced by outside environment.

4- Cooling system with cold air cycle ensures same heat exposure of internal and external surface.

Blower Part

1 - Short mould stroke,quick action. 2- Wide adaptability, suitable for every type mould thickness. 3 -Special design,high rigid compound die structure. 4 -High responsiveness pneumatic components,action timely and precisely. * Small size, low investment. One person enough to operate, simple and safe.