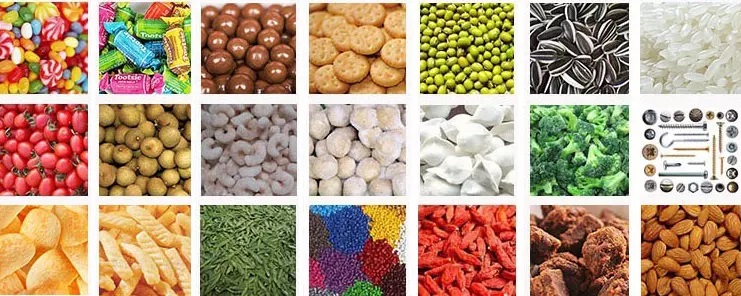

automatic weighing packing machine for banana chips potato chips chest nuts and coffee beans

| Price | $173.00/Piece |

| Min quantity | 10Piece |

| Quantity | 10000Piece |

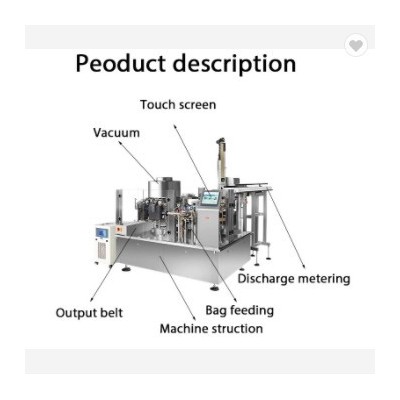

Features and Characteristics:

1. The packaging system consists of a rotary packing machine, a work platform, an electronic scale,

z-bucket elevator.

2. Fast and stable performance

3. Waterproof system makes cleaning easier. Color touch screen display, easy to operate.

4. Provide an innovative solution at a reasonable cost.

5. The machine adopts premade perfect-pattern pouch, with high-quality sealing.

Work Process:

bag giving→date coding →bag opening →filling and vibrating 1→filling and vibrating2→heat sealing 1→heat sealing 2→forming and output

1.Z shape Bucket Conveyor

It’ s suitable use in delivery the grain, food, food stuff etc.

Conveyor with the character of large quantity. NO crash material. High Lifting etc.

Lifting height:3.3-10m(according to customer’s requires)

It can be made both stainless steel and plastic painted .The contact parts of food grade plastic.

2.Multihead Weigher

*High precision data-type weighing sensor realizes precise weighing.

*Liquid crystal screen operating system in multiple languages such as Chinese and English, etc.

*IP65 grade water-proof and dust-proof design. It’s clean and sanitary with all stainless steel parts. Full sealed design prevents

accumulation of material and facilitates cleaning.

*It can fine the opening and closing speed of hopper door according to the features of items to be weighed, and prevent crushing

and blocking of material.

*With powerful digital automatic counting function, it can record the index for each batch of product such as total bag number,

pass rate and difference of single bag, etc.

*Optional devices: triply balance ball, suction hopper, printing device, tolerance sorting device.

3.Take -off Conveyor

frame ,belt and chain plate is optionall ,height of output can be modified .The machine can send the packed finished bag to

after-package detecting device or packing platform.

Product Paramenters

(Don't Worry! We have several Models. We can recommend you according to your requirement. Just Tell Us: Capacity, Filling machine and Capsule Size.)