Overview

Essential details

Applicable Industries:

Manufacturing Plant, Machinery Repair Shops, Printing Shops

Showroom Location:

None

Video outgoing-inspection:

Provided

Machinery Test Report:

Not Available

Marketing Type:

Hot Product 2019

Warranty of core components:

1 Year

Core Components:

PLC, Motor

Condition:

New

Automatic Grade:

Automatic

Place of Origin:

Anhui, China

Brand Name:

INNOVO

Weight:

4500 KG

Warranty:

1 Year

Key Selling Points:

Automatic

After Warranty Service:

Video technical support

Local Service Location:

None

After-sales Service Provided:

online support

Supply Ability

Supply Ability

20 Set/Sets per Month

Packaging & delivery

Packaging Details

40HQ

Port

China seaport

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 30 To be negotiated

Video Description

Automatic paper-pile turning machine

Product Description

The printing industry at present, a new generation of printing machine operator has more reluctant to engage in high intensity of labor jobs(such as paper-pile flip, etc.), and the labor cost is higher and higher in recent years. Printing and packaging enterprises are the trend of the times to equip with paper-pile flip sorting machine in processing of sheet -fed printing and packaging, etc. Whereasin Occident, average two sets of sheet-fed printing will equip a set of paper-pile flip sorting machine. Our company combined with the advanced technology of foreigh products, through years of development and testing, now our new product has a fothold in the market. Our company goal is to make most of printing enterprises strive to equip a set of paper-pile flip sorting machine for every three sets of printing press, in order to reduce the labor intenity, enhances the working efficiency in printing enterprise.

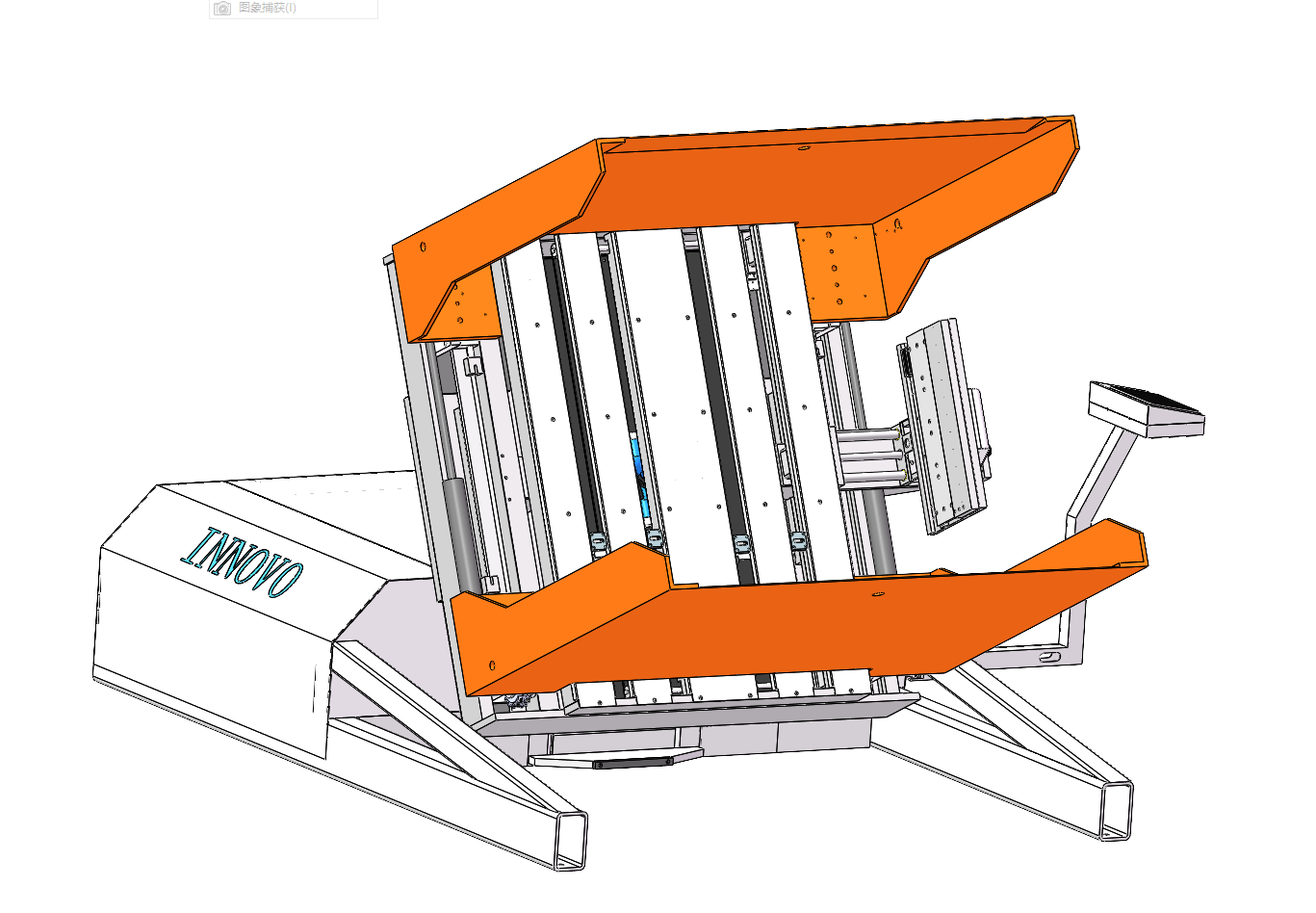

Machine details:

1. Paper-pile flip sorting machine is belong to printing auxiliary equipment, it has turning, airing, jogging and aligning functions, the optional includes antistatic device(onic wind).

2. Paper flip is using for double side printing, turning to print back side after the front side printed, or turning to print front side after coating on back side(such as mildew, moth-proofing, moisture proof light oil etc); through paper-pile flip to alleviate the printed paper, which stored for a ong period become warped edge and edge of crimp degree. Lots of different types of paper need to flip such as CCNB is printed on the grey bottom only, TRL is printed on the white bottom only, offset paper printing opposite , etc.

3. Airing and dust removing, jogging, reducing impurities such as lint and paper scrap, improving the surface quality of the paper, reducing double feeding, clear spray the powder, speed up ink drying, reducing paper adhesion and set-off, reducing ink scent, improve production efficiency and product quality.

Main features:

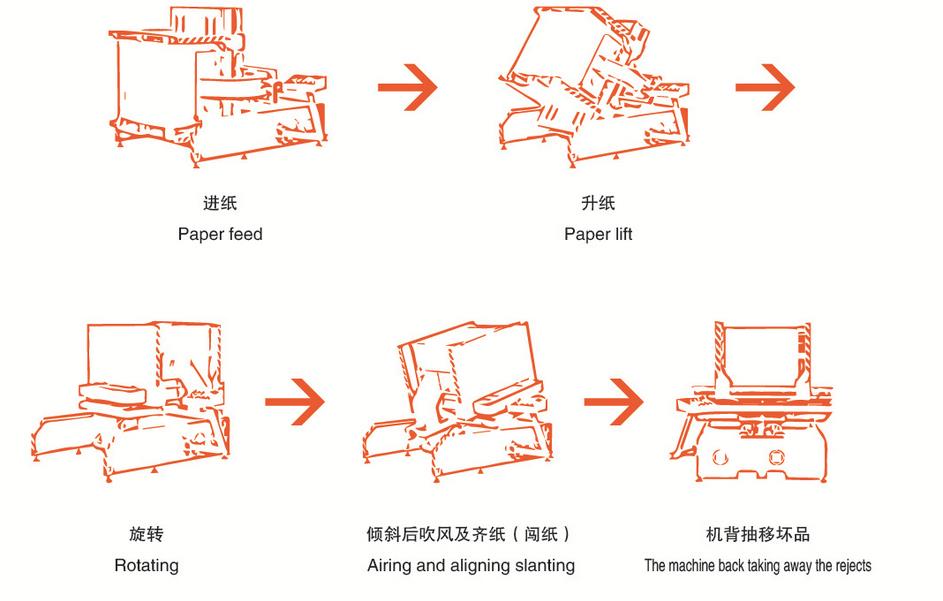

1. To promote post-printing process efficiency.

2. To maintain the highly efficient production capacity of the printer.

3. To finish the paper-pile rollover in one minute.

4. To finish the paper-pile aligning, dust removing and rollover within 4-5 minutes on average.

5. To do operation without professtional staff.

Workflow:

| Model | ZX-1650 |

| Max sheet size | 1220*1650mm |

| Loading weight | 1900kg |

| Platform width | 1800mm |

| Platform depth | 1235mm |

| Max pile height | 1600mm |

| Min pile height | 830mm |

| Power | 17kw |

| Length | 2790mm |

| Width including operating rod | 2060+1340mm |

| Height | 2260mm |

| Machine weight | 4500kg |

Company Information

*With 10 years' Experience

*Having ISO 9001-Certified Factory

*Strong R&D capability

*High Quality Guaranteed

*First Class Service And Best Prices

*Primary products:

Automatic High Speed Flute Laminater

ZXSCM Book Case Making Machine

650UV Coating Machine

ZX-650C Manual Paper Pasting Machine

Box Making Machine

Hot Melt Gluing Machine and Gluing Machine

Table Gluing Machine

Paper Pressing Machine.etc

Welcome to visit our factory!