Overview

Essential details

Type:

Gluing Machine

Applicable Industries:

Manufacturing Plant

Showroom Location:

Egypt, Italy, Morocco, Algeria, South Africa

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty of core components:

1 Year

Core Components:

Engine, Motor

Condition:

New

Application:

Food, Commodity

Packaging Type:

Paper Box

Packaging Material:

Paper

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

380V

Place of Origin:

Shanghai, China

Brand Name:

PRINTYOUNG

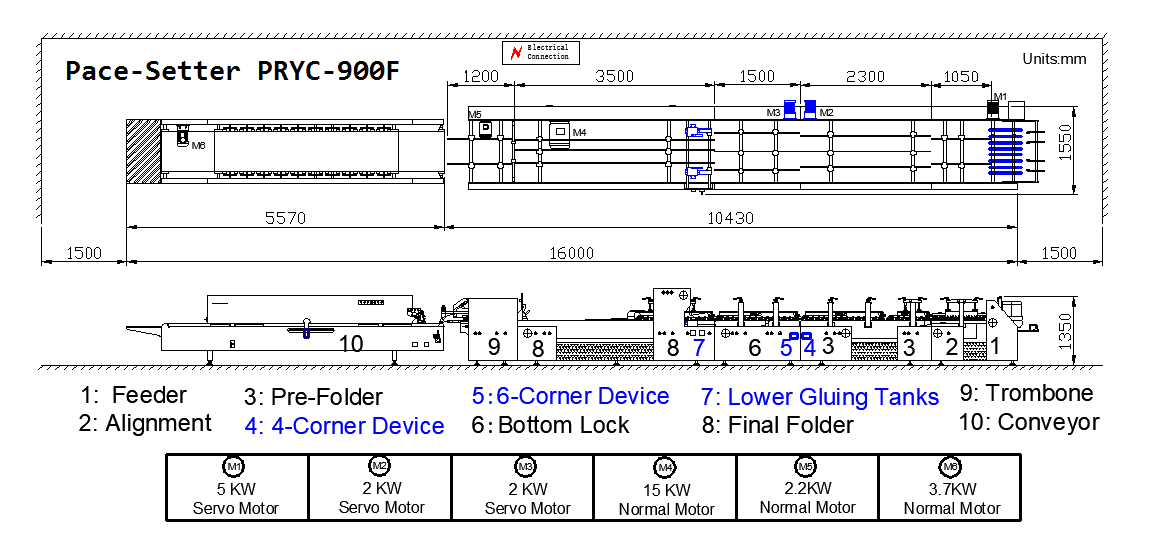

Dimension(L*W*H):

16000*1550*1900mm

Weight:

7000 KG

Warranty:

1 Year

Key Selling Points:

Multifunctional

Model:

PRYC-900F

Cardboard:

200~800 gsm

Corrugated Flute Type:

E-flute and F-flute

Speed:

Max. 400 m/min

Paper Width Size:

Max. 950 mm, Min. 86 mm

Electrical Connected Load:

31 KW

Power Supply:

380 Volts 3 Phase 50 Hz

Compressed Air:

6 bar

Air Compressor Capacity:

10 m³/h

Air Tank Capacity:

60 L

Supply Ability

Supply Ability

20 Set/Sets per Month

Packaging & delivery

Packaging Details

Packing is with steel pallets, suitable for long-distance road and vessel transportation and various types of weather conditions.

Port

Shang Hai

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 30 To be negotiated

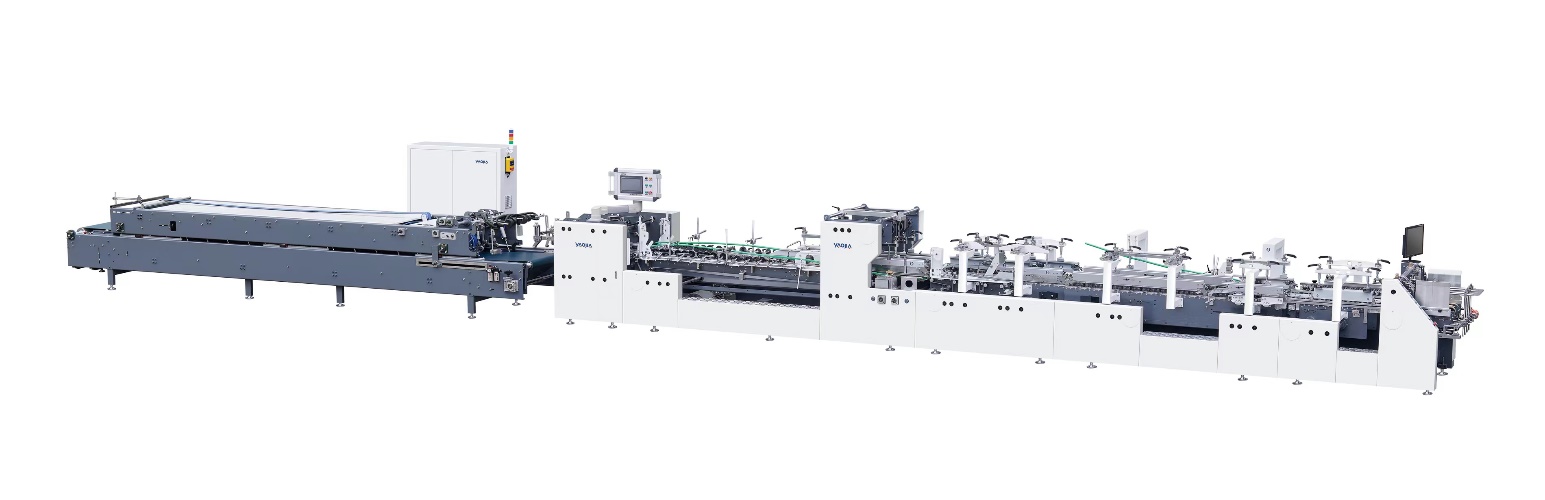

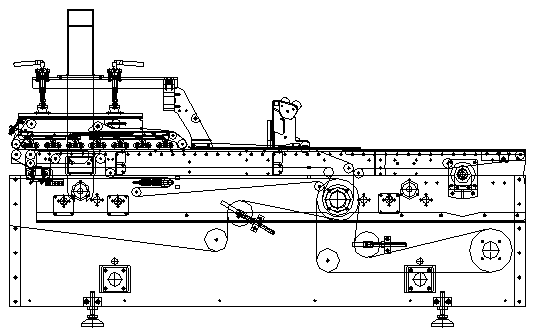

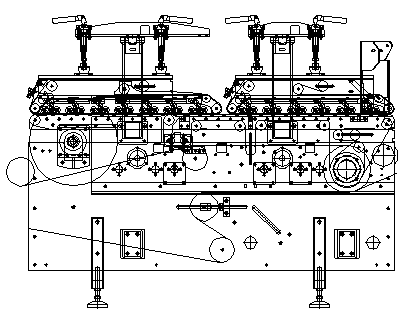

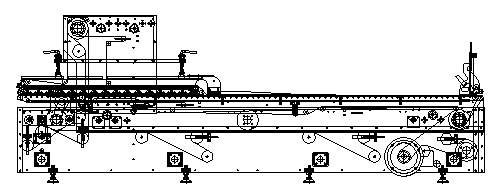

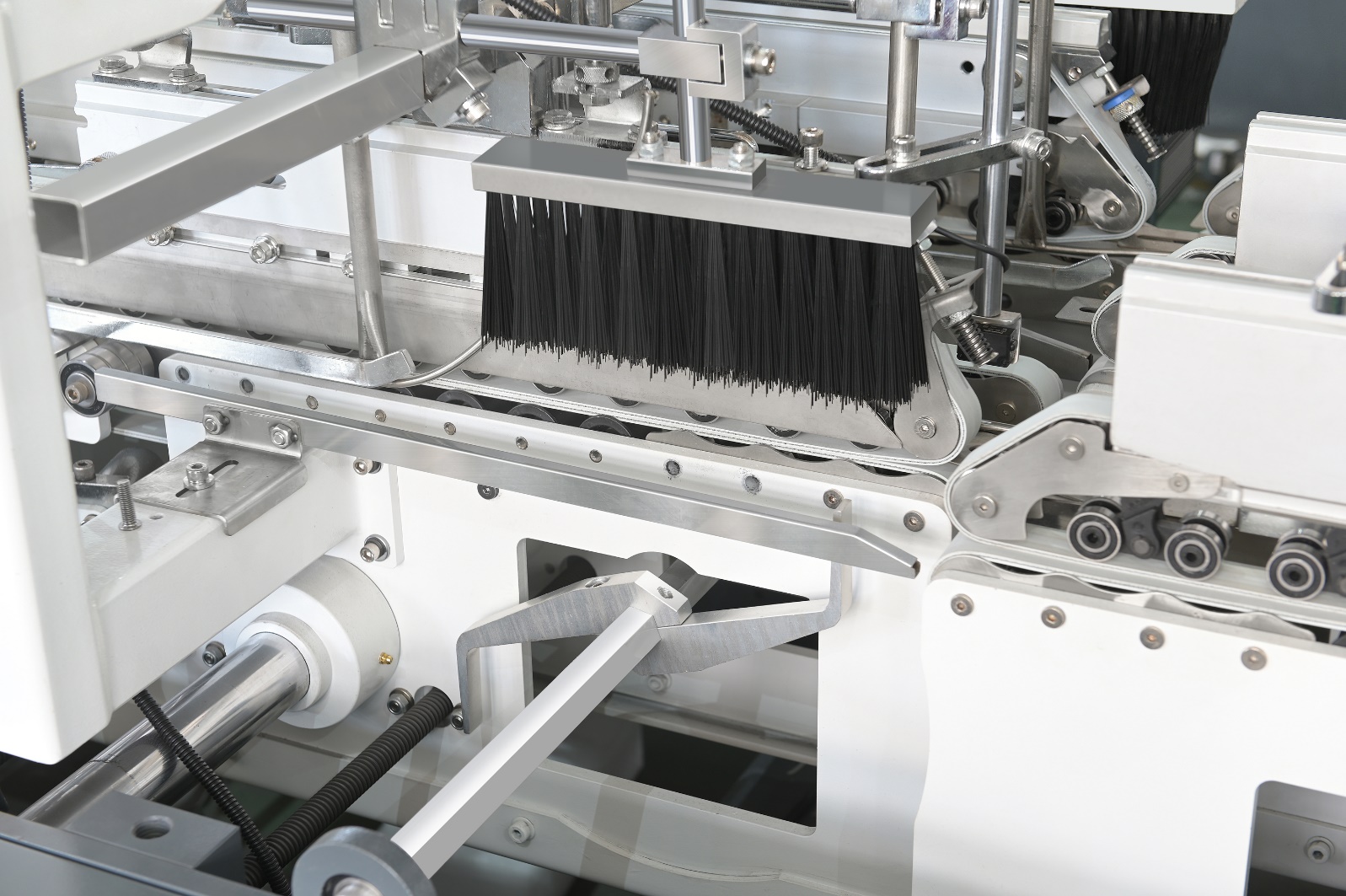

PRYC-900F Folder Gluer Machine

Features

Pace-Setter PRYC-900F for straight line box,bottom lock box,4&6 corners box,side glue box,box inside box,mini box and some other special-shaped box(irregular box)of high-speed production.The machine max speed is 400 meters/min.Suitable for cardboard

200~800 gsm,corrugated board E-flute and F-flute.

Technical Parameters

Configuration

Feeder

*Fully automatic feeder with servo motor

5 KW

*8pcs 30mm Friction Belts Soft Rubber

Compound (optional extra 4 vacuum belts)

*4 Back Carton supports

*3 Front paper supports (Quick adjustment for thickness of substrate)

*2 Paper Side guides

*Vibrator

*Video screen monitor (view final product at the end of the Machine)

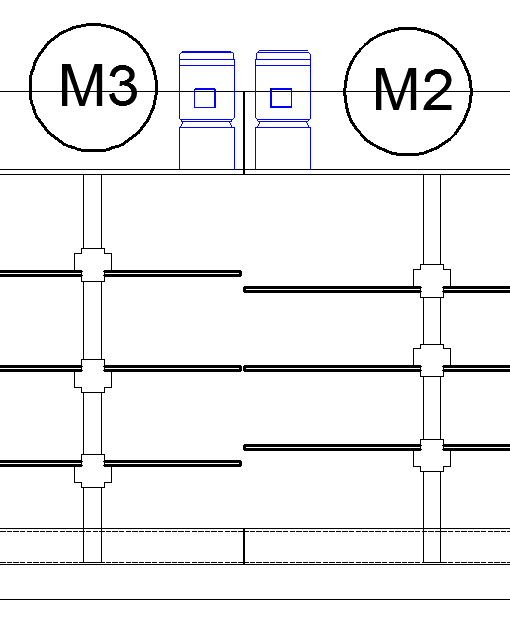

Aliening Unit

*2 Bottom Transport Carriers(fitted with 34mm wide Belts)

*1 left Hand Side Squaring Guide

*1 Right Hand Side Squaring Guide

*4 Top paper support guides

*Adjustable top Carriers fitted with independent lever system which can be independently applied giving the desired pressure required for the alignment of Substrate carton blank

Pre Fold Unit

*1st and 3rd Crease Pre Folding up to 180 and 135 degrees helping to break the fiber of rigged board

*Bottom left had side carriage 43 millimeter wide belt

*3 Bottom Carriers

*3 Top carriers

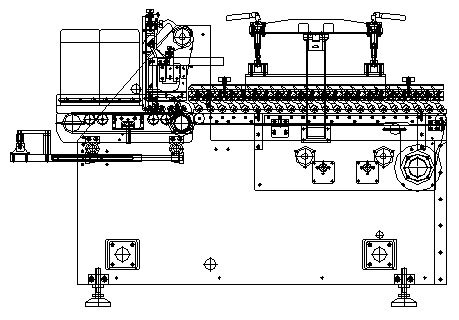

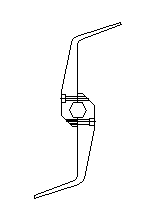

Crash Lock Unit

*3 Bottom Transport carriers

*3 Top Transport carriers

*4 Sets of crash lock hooks

*3 Sets of diagonal folding shoes 2 Unit per Set

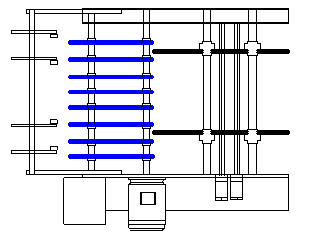

4 And 6 Corner Device

*2 Servo Drive Motors 2kw Each

*3 Folding Hooks 4 Corners

*3 Folding Hooks 6 Corners

*6 Corner Box Lid Can Be Folded from the Left or Right hand side Of Machine

*Moveable Touch screen Commander Module(For programing Measurement’s:Speed and position and Electronic angel of the folding Hooks)

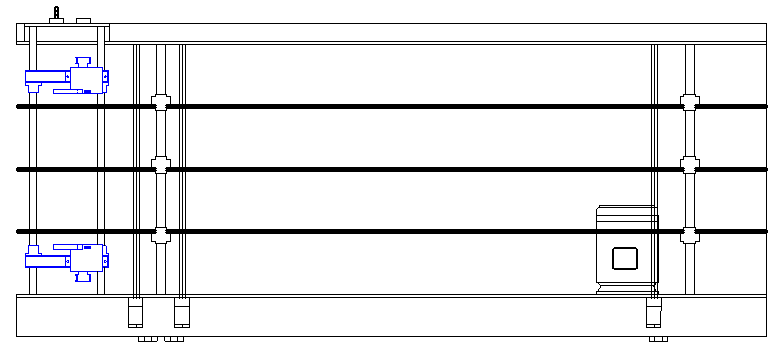

Final Folding Unit

*Folding 2 and 4 crease

*3 carriers

*Removable Center top and bottom carriers

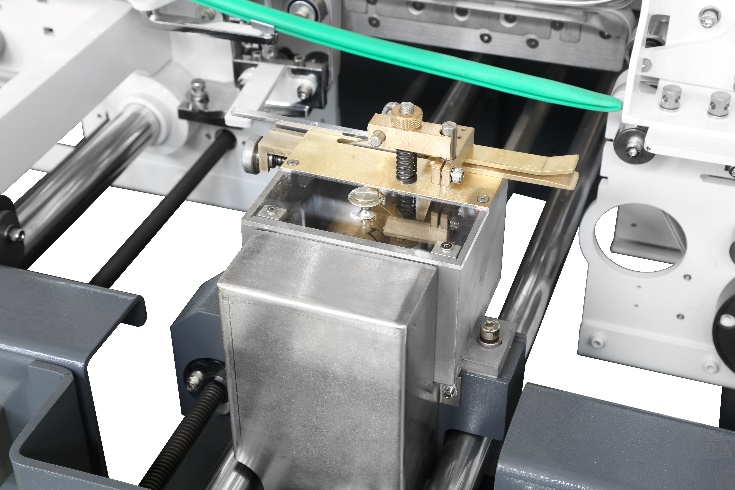

*Equipped with 2 glue tanks 1 Left 1 Right with 4 M/m disc

*Adjustable speed control of belts left and right

Trombone Unit

*Double Trombone (Telescopic)

*Dirven by 2.2KW motor independently

*Moveable Touch screen Commander Module

*Pressing Roller Device

Pressing Unit

*1 Drive Motor(Standard 3.7 KW)

*Front and Backward position

*Pneumatic pressing (Adjustable via Pneumatic Regulator valves)

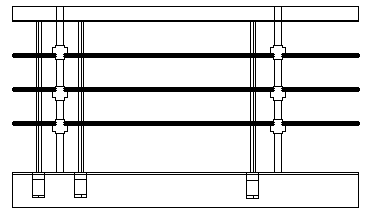

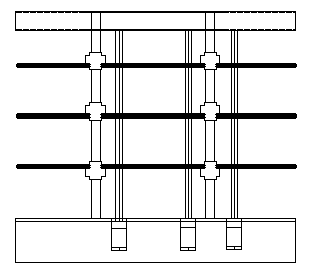

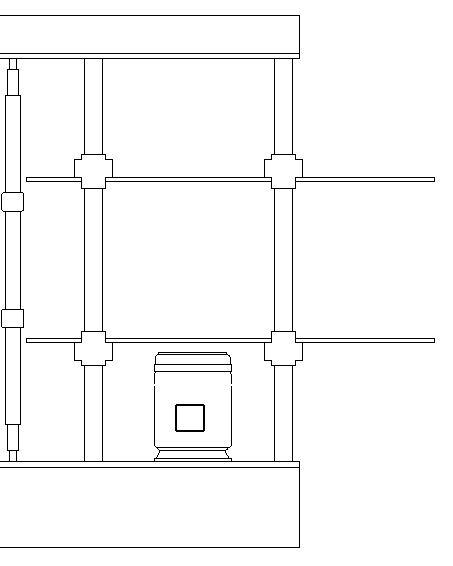

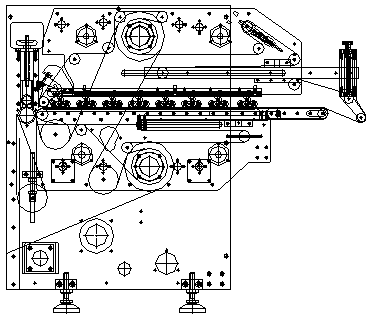

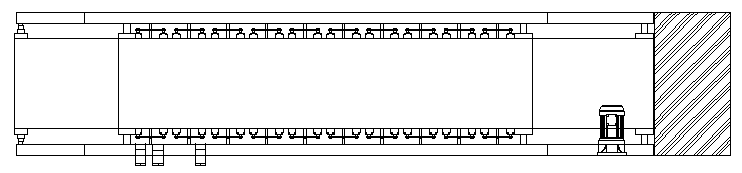

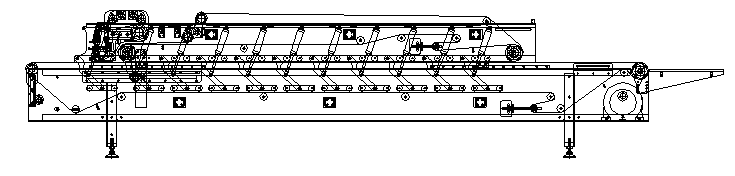

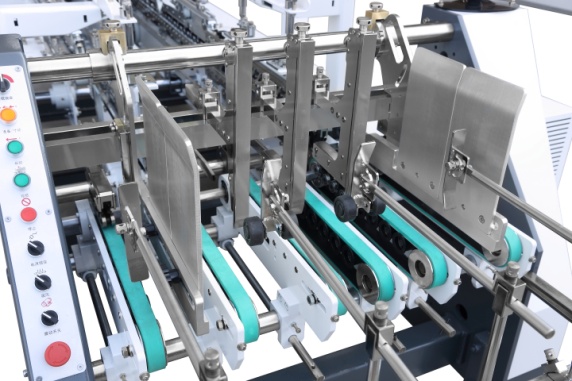

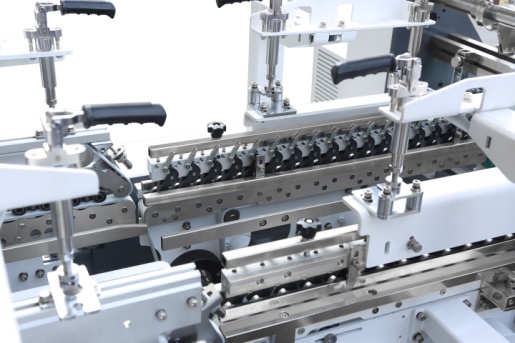

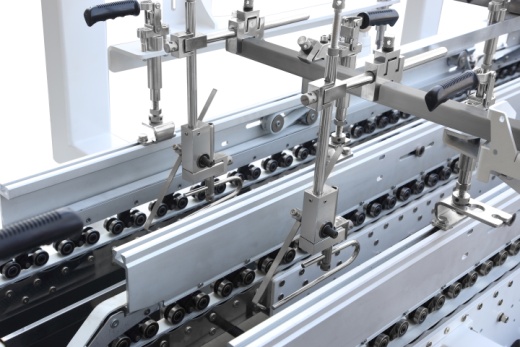

Machine Pictures

Q1.Are you a manufacturer or a trading company?

A:Our shanghai office is mainly doing export.

We have our own factory in Wenzhou,Zhejiang Province.

Q2.What is the machine warranty?

A:One year.After the warranty,we still provide technical support to buyer at low cost.

Q3.What is the production time while placing order?

A:Normally about 10-20 days.

Q4.What is the delivery time?

A:15-30days after deposit.

Q5.Can your company handle shipping for customers?

A:Yes,just give us destination sea port or container yard.

Q6.Does the packing strong?

A:Yes.Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions.

A full set of maintenance and operation manuals is included.

Q7.How about the machine installation and training?

A:1)We provide training in our factory for free;

2)We can send technicians (engineers) to your factory for installation and training.

You shall pay the round trip air fare and accommodations,plus each technician charges USD100/per day.

Q8.Do you have machines in stock?

A:For standard model,we have a large quantity in stock.

For special model,we need 20-30 days to produce it for you.

Q9.How can you assure the machines’ quality?

A:Each machine will be test running at least 24 hours before delivery to assure the quality.

And during the warranty,we will give spare parts for free if machine has any problem.

Q10.Do you inspect machines or test running before packing?

A:Of course we do.We have QC department to debug the machine before packing.

If you want to use specific material to do the test running,you need to pay for the cost of the material.

Q11.What’s the payment term?

A:T/T 30% in advance,the balance shall be paid before delivery.

We also accept payment by West Union or L/C at sight.

Q12.Do you accept factory visiting?

A:Warmly welcome for your visiting.

Q13.How many years are you in printing field?

A:Shanghai company is 12 years old, the factory is more than 20years.

Q14.How many clients do you have?

A:We have sold our machines to about 60 countries.

We have agents in South Africa,Morocco and Italy.