Overview

Essential details

Applicable Industries:

Home Use, Other

Showroom Location:

Egypt, Italy, Morocco, Algeria, South Africa

Condition:

New

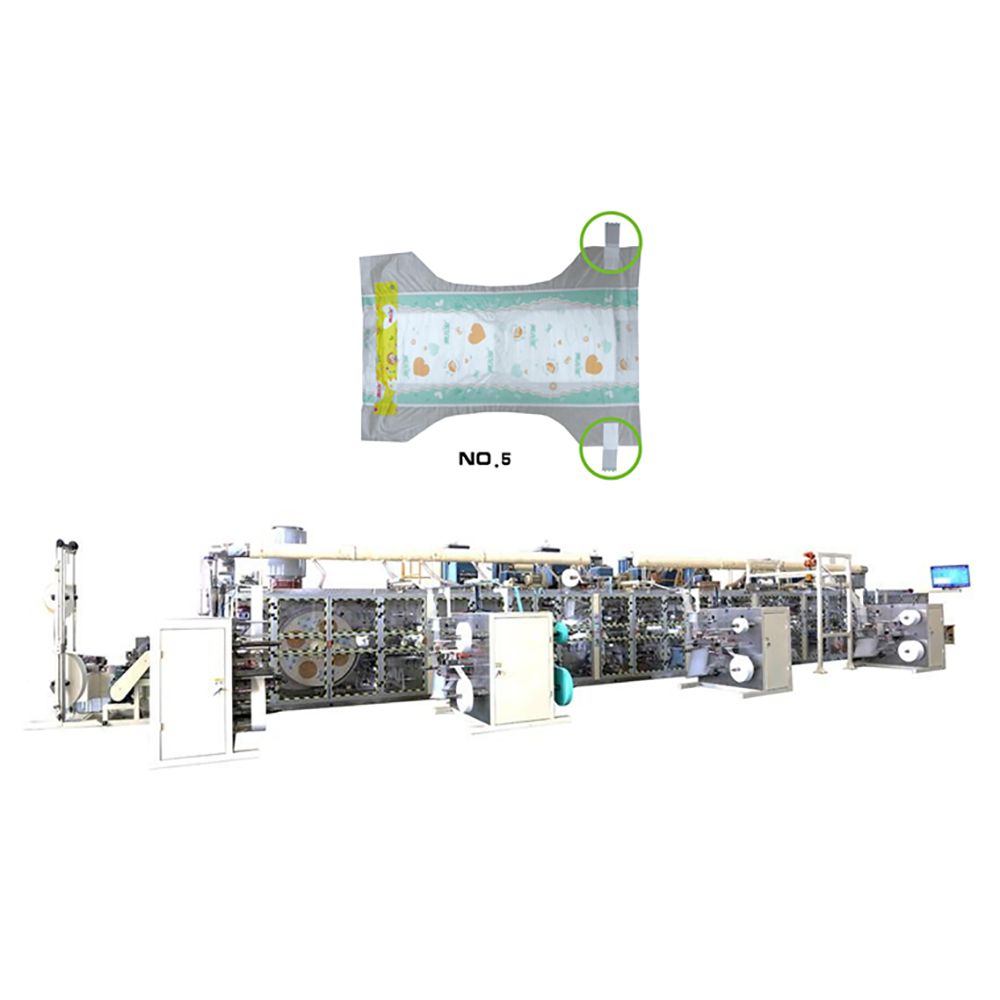

Product Type:

baby diaper machine

Processing Type:

Other

Place of Origin:

Zhejiang, China

Brand Name:

PRINTYOUNG

Voltage:

380V

Power:

300 KW (main machine)

Dimension(L*W*H):

25*2.1*4.8 M

Weight:

82000 kg

Warranty:

1 Year

Production Capacity:

550pcs/min

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Marketing Type:

Other

Warranty of core components:

1 Year

Core Components:

Other, Engine, Motor

Finished Products:

baby diaper

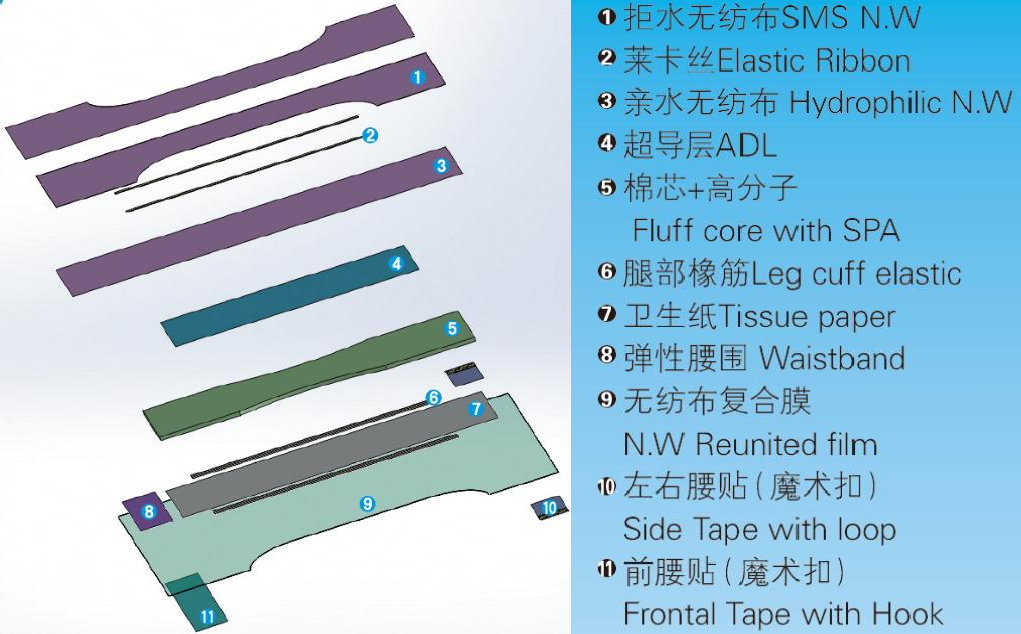

Raw Material:

Paper

Qualified rate:

≥ 97%

Efficiency:

≥ 85%

Electricity:

380V,50HZ (Accept customized)

Air pressure:

6 kg/cm2 ≥0.8mpa

Working space:

33*10*5.5 M (L*W*H)

Machine color:

Rice white ,can be changed by order

Product size:

S,M,L,XL

Containers:

5X40HQ

Supply Ability

Supply Ability

20 Set/Sets per Month

Packaging & delivery

Packaging Details

wooden case

Port

Shang Hai

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 45 To be negotiated

baby diaper machine

Technical Parameters

Spare Parts List

Factory-Set-Up Demands

1.Without vibration,clean and clear environment,good ventilation,no flammable and explosive and corrosive substances around.

2.Flat concrete ground,concrete number should be at least 300#;ground level difference should be within 15-25mm,so that machine adjustment is more convenient.

3.Ground should have enough bearing capacity.Concrete ground thickness is no less than 200mm.if machine is put on the 2nd floor,concrete floor(reinforced concrete pouring) average bearing capacity is at least 3.5tons/sm.machine is put no more than on the 2nd floor.

4.To keep at least 1 meter distance between the back side of machine (including attached equipment) and the walls.

5.To prevent the accident due to the uneven ground.

6.The inside temperature in the factory is no less than 12-15.

Q1.Are you a manufacturer or a trading company?

A:Our shanghai office is mainly doing export.

We have our own factory in Wenzhou,Zhejiang Province.

Q2.What is the machine warranty?

A:One year.After the warranty,we still provide technical support to buyer at low cost.

Q3.What is the production time while placing order?

A:Normally about 10-20 days.

Q4.What is the delivery time?

A:15-30days after deposit.

Q5.Can your company handle shipping for customers?

A:Yes,just give us destination sea port or container yard.

Q6.Does the packing strong?

A:Yes.Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions.

A full set of maintenance and operation manuals is included.

Q7.How about the machine installation and training?

A:1)We provide training in our factory for free; 2)We can send technicians (engineers) to your factory for installation and training.

You shall pay the round trip air fare and accommodations,plus each technician charges USD100/per day.

Q8.Do you have machines in stock?

A:For standard model,we have a large quantity in stock.

For special model,we need 20-30 days to produce it for you.

Q9.How can you assure the machines’ quality?

A:Each machine will be test running at least 24 hours before delivery to assure the quality.

And during the warranty,we will give spare parts for free if machine has any problem.

Q10.Do you inspect machines or test running before packing?

A:Of course we do.We have QC department to debug the machine before packing.

If you want to use specific material to do the test running,you need to pay for the cost of the material.

Q11.What’s the payment term?

A:T/T 30% in advance,the balance shall be paid before delivery.

We also accept payment by West Union or L/C at sight.

Q12.Do you accept factory visiting?

A:Warmly welcome for your visiting.

Q13.How many years are you in printing field?

A:Shanghai company is 12 years old, the factory is more than 20years.

Q14.How many clients do you have?

A:We have sold our machines to about 60 countries.

We have agents in South Africa,Morocco and Italy.