Overview

Essential details

Type:

Gluing Machine

Applicable Industries:

Garment Shops, Manufacturing Plant, Food & Beverage Factory, Printing Shops, Advertising Company

Showroom Location:

Italy, Morocco, South Africa

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty of core components:

1 Year

Core Components:

PLC, Bearing, Gear

Condition:

New

Packaging Type:

case

Packaging Material:

Wood

Automatic Grade:

Automatic

Driven Type:

Electric

Place of Origin:

China

Weight:

11000 KG

Warranty:

1 Year

Key Selling Points:

Easy to Operate

Marketing Type:

New Product 2020

Supply Ability

Supply Ability

20 Set/Sets per Month

Packaging & delivery

Packaging Details

wooden case

Port

Shang Hai

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 45 To be negotiated

PCS-1450 Automatic Folder Gluer

Features

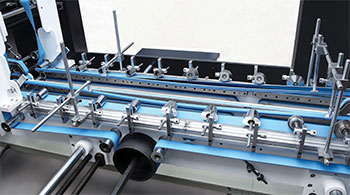

PCS Series folding gluing machine with 4/6 corner function, each set is controlled by independent motor adopts electrical regulating board, PLC, imported electronic components, three plates track mode device. Aluminum plates are all Chute structure, which is easy to add spare parts. The machine is especially designed for all kinds of 4/6 corner cardboard or corrugated packaging boxes, which can meet to all kinds of requirements of automatic packaging field.

Technical Parameters

Configuration

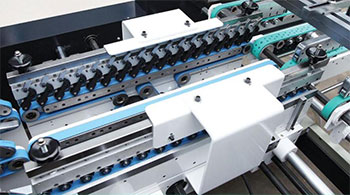

1. Paper Feeding Section

Feeding belts equipped with the function of air suction

Equipped with new type of feeding knife. You can adjust them according to the box shapes.

With special pushing teeth function, easy to adjust the backing board.

Vibration device coordinate with motor which helps machine consecutive and automatic feeding quickly and simply

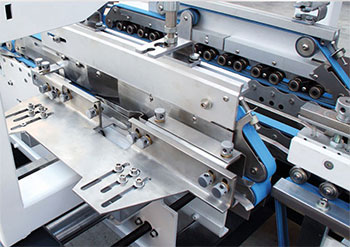

2.Aligner section

The paper board sent from feeder section will be corrected by aligner section to ensure transmission accurately.

Pressing drive pressure can be adjusted up and down to accommodate different paper board thickness.

3.Electromagnetic Heater

Equipped with advanced electromagnetic heater. Fast pre-heating. Energy saving. Environmental protection.

4.Human-computer interface

A user-friendly interface system with a colour touchscreen simplifies the operation process. The operator can easily and automatically control paper sizes, overlapping and machine speeds.

5.Pre-folding section

Special first folding line pre-fold 180°. third line 165° ,which perfectly meeting the requirements of automatic packaging

industry.

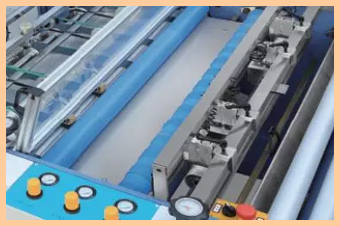

6. Lower gluing tank

Lower gluing tank is large volume.

Easy to remove and clean

Electronic upper gluing system by guns.

7. Folding and closing

The upper pressure belt adopts main drive and cylinder pressure, is mainly

used for the production of different thickness of corrugated products.

Equipped with flexible box forming device to ensure the perfect forming of the box.

Q1: Are you a manufacturer or a trading company?

A: Our shanghai office is mainly doing export. We have our own factory in Wenzhou, Zhejiang Province.

Q2. What is the machine warranty?

A: One year. After the warranty, we still provide technical support to buyer at low cost.

Q3. What is the production time while placing order?

A: Normally about 10-20 days.

Q4. What is the delivery time?

A: 15-30days after deposit.

Q5. Can your company handle shipping for customers?

A: Yes, just give us destination sea port or container yard.

Q6. Does the packing strong?

A: Yes. Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions. A full set of maintenance and operation manuals is included..

Q7. How about the machine installation and training ?

A: 1)We provide training in our factory for free; 2)We can send technicians (engineers) to your factory for installation and training. You shall pay the round trip air fare and accommodations, plus each technician charges USD100/per day.

Q8. Do you have machines in stock?

A: For standard model, we have a large quantity in stock. For special model, we need 20-30 days to produce it for you.

Q9. How can you assure the machines’ quality?

A: Each machine will be test running at least 24 hours before delivery to assure the quality. And during the warranty, we will give spare parts for free if machine has any problem.

Q10. Do you inspect machines or test running before packing?

A: Of course we do. We have QC department to debug the machine before packing. If you want to use specific material to do the test running, you need to pay for the cost of the material

Q11. What’s the payment term?

A: T/T 30% in advance, the balance shall be paid before delivery. We also accept payment by West Union or L/C at sight.

Q12. Do you accept factory visiting?

A: Warmly welcome for your visiting.

Q13. How many years are you in printing field?

A: Shanghai company is 12 years old, the factory is more than 20years.

Q14. How many clients do you have?

A: We have sold our machines to about 60 countries. We have agents in South Africa, Morocco and Italy.