OverviewEssential details

Type:

Flexographic Printer

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other

Condition:

New

Plate Type:

Letterpress

Place of Origin:

Zhejiang, China

Brand Name:

LISHENG

Usage:

Card Printer, Label Printer, Paper Printer

Automatic Grade:

Automatic

Color & Page:

Multicolor

Voltage:

220v 50HZ

Dimensions(L*W*H):

5500*1900*3000mm

Weight:

5000 KG

Warranty:

1 Year

Key Selling Points:

Multi Color

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Bearing, Motor, Pump, Gear, PLC, Pressure vessel

Structure:

Stack

After-sales Service Provided:

Engineers available to service machinery overseas

Printing speed:

10-100m/min

Color:

4 Color

Material:

Pe Opp Bopp Paper

Machine type:

Letterpress Printing Machine

Material width:

600mm

Total power:

25kw

Plate thickness:

2.84mm

Machine weight:

5000kg

Overall Diamension:

5500*1900*3000mm

Supply Ability

Supply Ability

2 Set/Sets per Month

Packaging & delivery

Packaging Details

film or wooden case

Port

ningbo port

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 30 To be negotiated

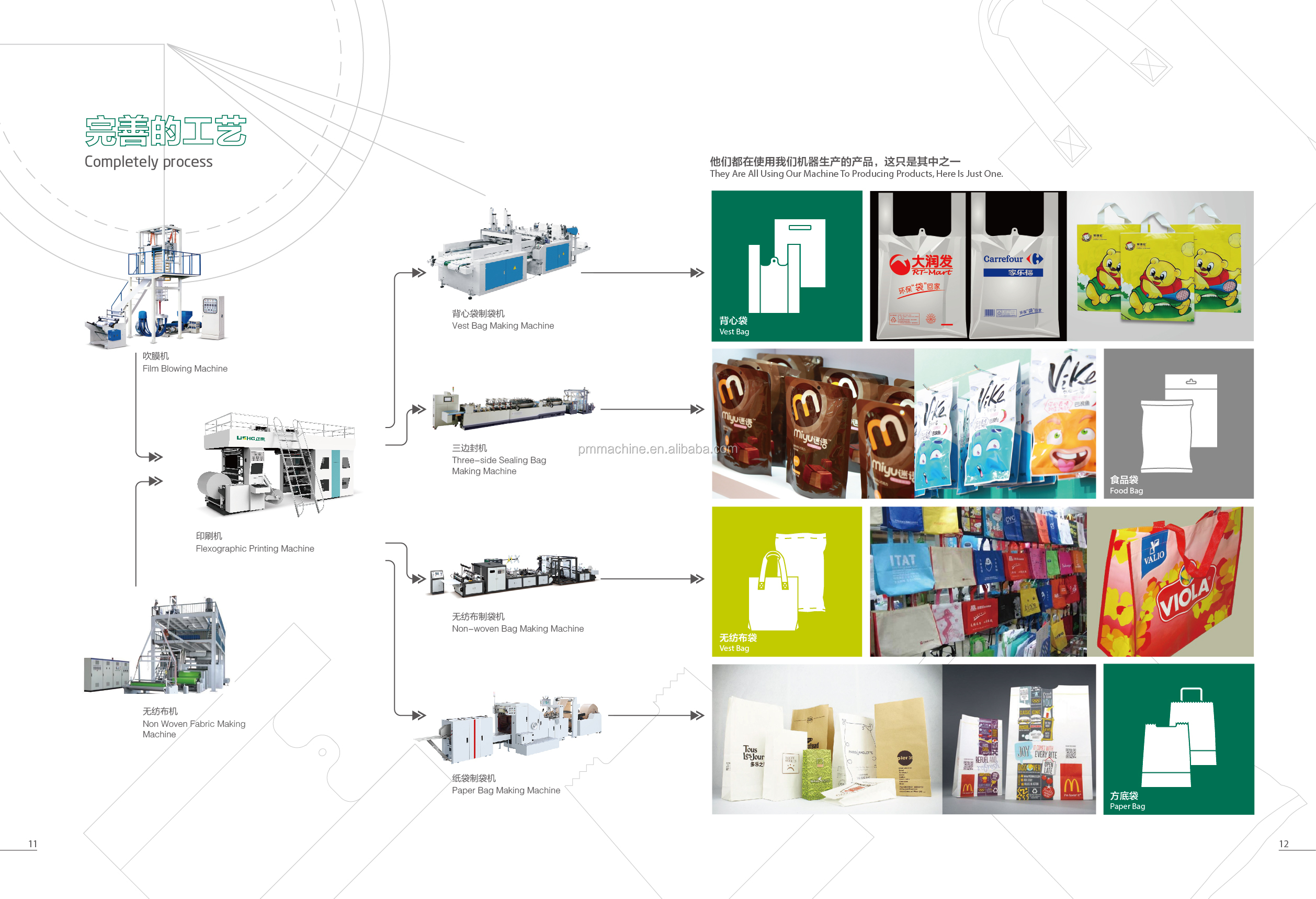

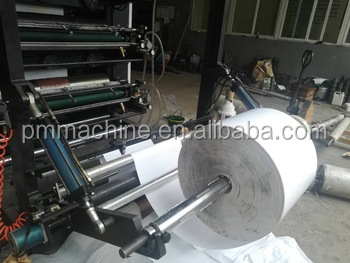

Video DescriptionProduct DescriptionThis machine is suitable for printing such packing materials as PE, PP bag, cellophane and roll paper, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Characteristics:

1.Easy operation, flexible starting, accurate color register. 2.The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off. 3.Manual printing cylinder lift and lower, it will stir the printing ink automatically after lifting. 4.The printing ink is spread by the anilox cylinder with even ink color. 5.Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops. 6.360°continuous and adjustable longitudinal register device. 7.The frequency control of motor speed adapts to different printing speeds. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed. Product configuration

Feeding material part:

1.Single unwinder system, pneumatic/hydraulic loader or by manual for unwind system for you choose 2.Automatic stop machine when break the material; When machine stop, keep tension and avoid the material loose or line deflection. 3.Air shaft 4.EPC (edge position control): With manually/automatically/ central return function, can adjust the rewind move left and right . 5.Automatic tension control system with magnetic brake(5KG). 6.Roller core diameter: 76mm 7.Discharge maximum diameter: 1000mm

Air shaft

Tight to material ,flat material , better printing

import Auto tension control & magnetic power (2 set )

Control un&rewind parts balance material both side.

Web guide (1set)(For optional)

Ultrasonic type swift tracking print photo

Web guide (1set)

Swift tracking print photo

Auto penumatic loading&unloading for unwinding

It is easy to transport and loading material. Material weight from 100kg ~500kg

verified

verified