Overview

Essential details

Type:

Flexographic Printer

Applicable Industries:

Manufacturing Plant, Printing Shops, Package Industry

Condition:

New

Plate Type:

Letterpress

Place of Origin:

Zhejiang, China

Brand Name:

LISHENG

Usage:

Paper Printer, Tube Printer, plastic film, Plastic Bag, Non Woven Bag, Paper Bag

Automatic Grade:

Automatic

Color & Page:

Multicolor

Voltage:

220V

Dimensions(L*W*H):

8800*2400*3700mm

Weight:

13500 KG

Print Dimension:

1200mm

Print Speed:

150m/min

Warranty:

1 Year

Key Selling Points:

Multi Color

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor, PLC

Structure:

CI

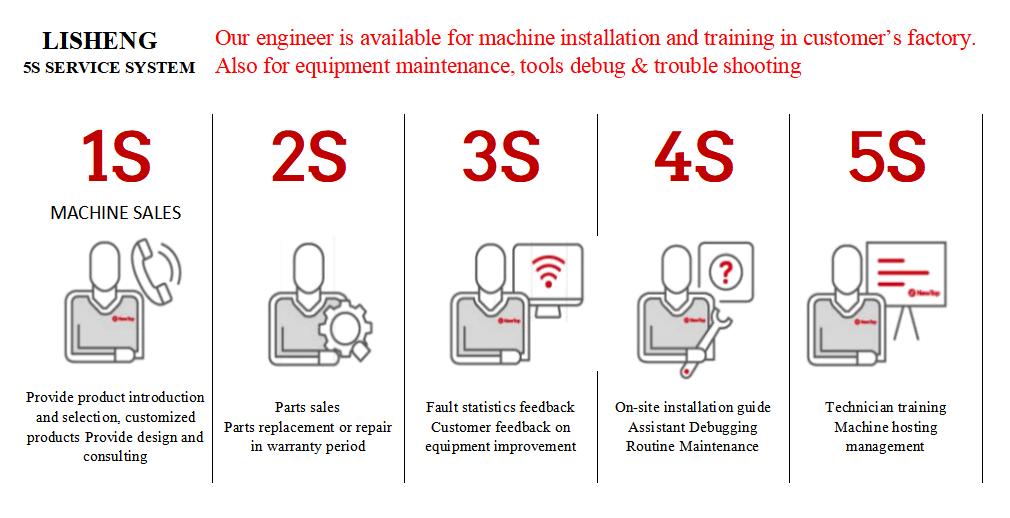

After-sales Service Provided:

Engineers available to service machinery overseas

Plate thickness:

1.7mm 2.84mm 2.28mm

Printing material:

Film, Paper.carton,non woven

Color:

6

Machine type:

YTC-61000

power:

23kw

Max Printing Width:

can be customized

Printing speed:

150m/min

Printing Length:

191-914mm

Anilox roller:

ceramic

Supply Ability

Supply Ability

10 Set/Sets per Month

Packaging & delivery

Packaging Details

Paper Roll central drum flexo printing machine for Handle bag packing: film cover

Port

NINGBO/SHANGHAI

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 60 To be negotiated

Video Description

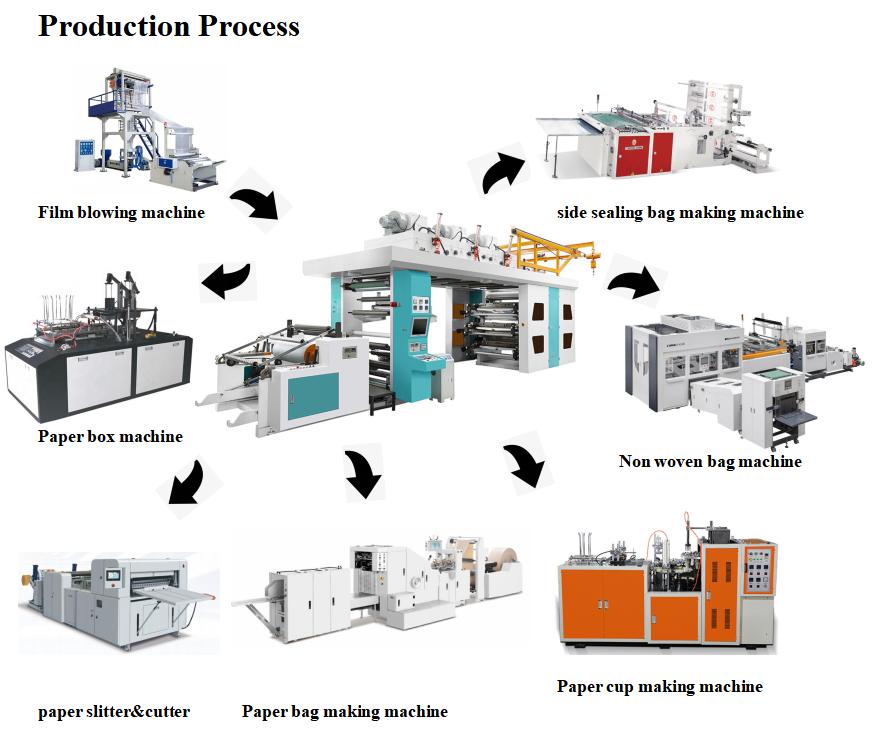

Product Description

Hot selling Central Drum 6 Color flexographic printing machine for poly bag paper roll

This central impression (central drum)flexographic printing machine is suitable for printing such packing materials as polyethylene, polyethylene plastic bag, leather, glass paper and roll paper etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

Sample pictures

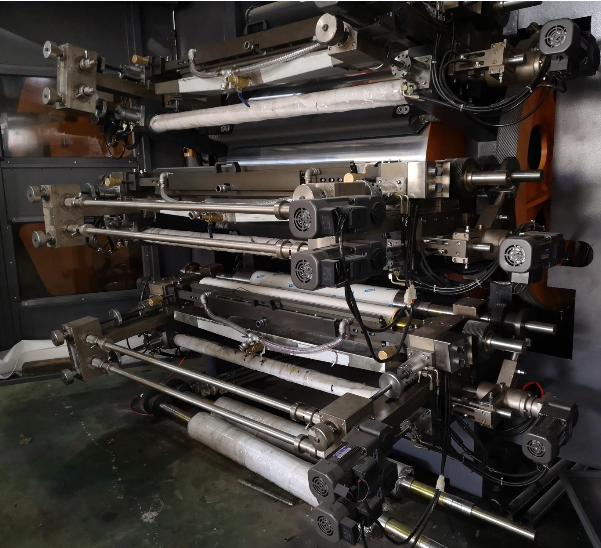

Details Images

Feeding Material Part

1.Automatic stop machine when break the material.

2.Single unwinding system, equipped with air shaft , EPC and automatic tension control system with magnetic brake.

3.Roller core diameter: 76mm

4.Discharge maximum diameter: 1000mm

5.Pneumatic load and unload material.

Printing Sections

1.Printing consists of: central drum, plate roller, ceramic anilox roller, single doctor blade and chamber doctor blade. 2.Plate roller circumference: 300-800mm. 3.Print material: resin plate or rubber plate. 4.Transmission: central drum with big gear drive the printing station.

Drying System

1.Use hot air drying, intelligent constant temp control.

2.Drying units are installed after the printing units, and air volume can be adjusted by independent damper/panel.

3. The drying system after the printing it is about 54kw.

Rewinding Part

1.Single unwind system, equipped with air shaft , EPC and automatic tension control system with magnetic brake.

2.Roller core diameter: 76mm

3.Discharge maximum diameter: 1000mm

4.Central type rewind

5.Pneumatic/hydraulic load and unload to transport and loading material.

PS: Above configurations just for your reference. Know more details please connect with us! Thanks and best regards!

Related Products

view more >>Recommended by seller

central impression flexible packaging 6 color flexographic printing machine woven bag flexography printer

$95,000.00 - $97,000.00 / set

1 set

six color high speed paper plastic film wrapper ci flexographic printing machine flexography printer

$100,000.00 - $105,000.00 / set

1 set

8 colors central drum baby diaper flexo printing machine plastic film flexographic printers

$110,000.00 - $120,000.00 / set

1 set

High accuracy central drum 6 color flexographic printing machine plastic film printing press

$100,000.00 - $105,000.00 / set

1 set

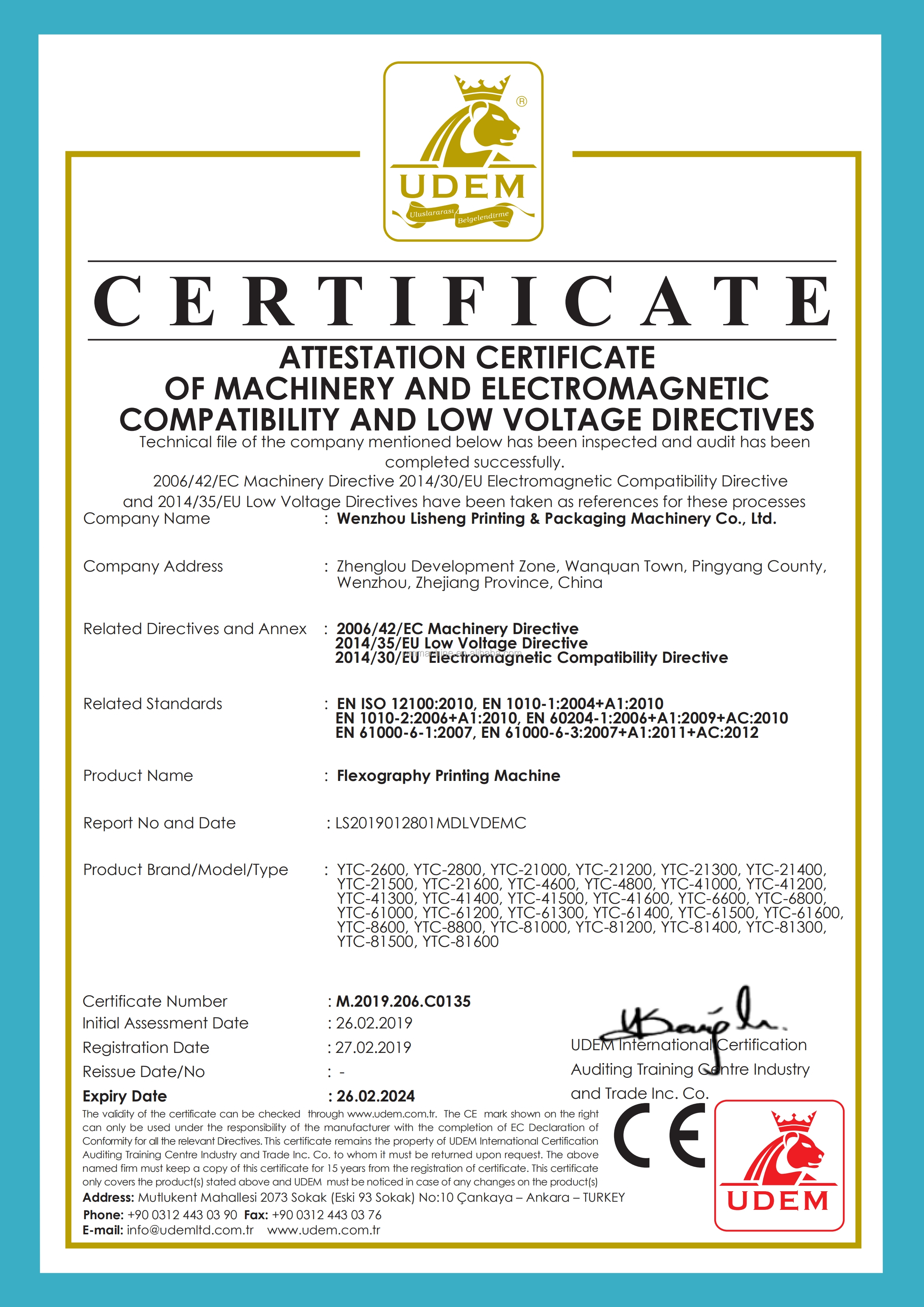

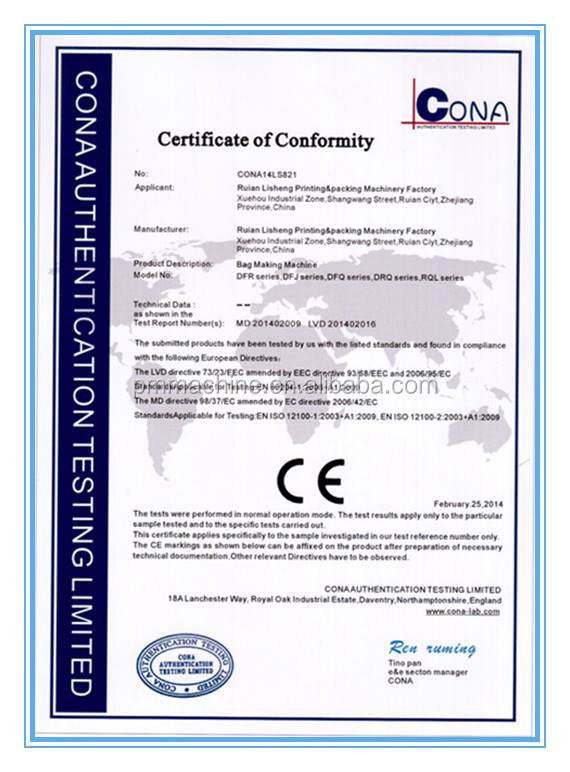

Certifications

Company information

After Sales Service

Installation:

The seller will send total 1 engineer for ci flexo machine, test the production line and train customers’ workers in buyers’ factory. It will take one week for whole installation and training.

The buyer should cover engineers’ salary, visa cost, round air tickets, accommodations, transportation in buyers’ country, food, medical care, safety cost, and related cost happens in buyers’ country. Also, the buyer should prepare enough labor, electric wire outside the control panel and tools for installations.

Engineer’s Salary:

USD 100/day, depending on how the engineer make you satisfied. The date he arrives and leaves shall be counted as paid day. The dates which wait for spare parts coming on seller’s duty are exclusive of salary paying.

Warranty:

Warranty period for the delivered equipment will be 12 month after the date customer receive the machine. In case any item proves to be defective and the damage is confirmed by seller’s technicians within this period, the seller will at their choice either send engineer to repair or supply a new one for replacement free of charge on the basis of CNF delivery.

The above item does not include the parts, which have regular spares or the parts damaged from normal wear, abnormal operation,

improper maintenance and inadequate civil works. The seller is not liable for any production loss under any circumstances.

Packing:

As per export standard, they will also be treated before delivery against damage and rusting.

FAQ

verified

verified