Overview

Essential details

Industrial Use:

Food

Use:

Other Food

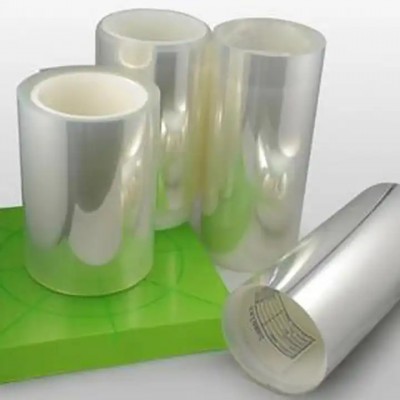

Material:

pet, PET

Type:

Transparent film

Usage:

Protection film, Packaging film,

Feature:

Heat resistance,Moisture Proof

Hardness:

Soft

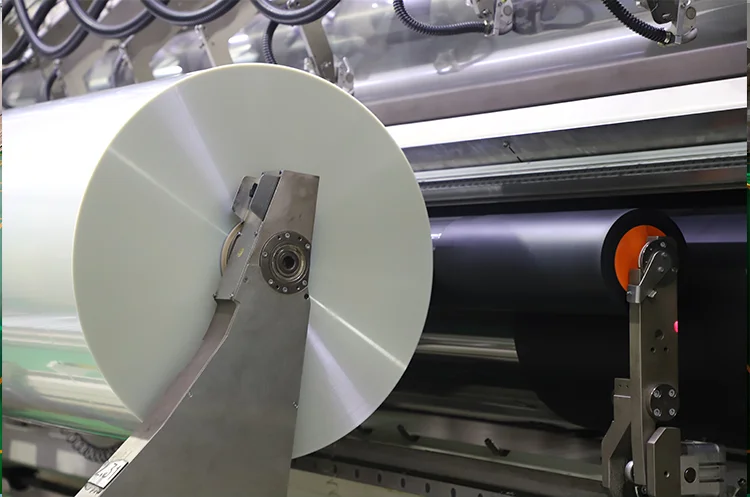

Processing Type:

Multiple Extrusion

Transparency:

Transparent

Place of Origin:

Jiangsu, China

Brand Name:

KOZA

Product name:

BOPET film

Color:

Transparent

Certificate:

ISO14001,ISO45001

Thickness:

8mic to 75mic

Width:

500-3300mm

Length:

600-3600m

Inner Core:

3" or 6"

Packing:

Wooden packaging

Size:

Customized

Sample:

A4 free Samples

Supply Ability

Supply Ability

120000 Ton/Tons per Year

Packaging & delivery

Packaging Details

Wooden pallet

Port

Lianyungang

Picture Example:

Lead time:

Quantity(kilograms) 1 - 1000 >1000 Lead time (days) 15 To be negotiated

Product Description

Project | Unit | Typical value | Test method | |

thickness | µm | 12~75 | GB/T 6672 | |

tensile strength | MD | MPa | 210 | ASTM D882 |

TD | 210 | |||

elastic modulus | MD | MPa | 3800 | ASTM D882 |

TD | 3800 | |||

elongation at break | MD | % | 100 | ASTM D882 |

TD | 100 | |||

heat shrinkage rate | MD | % | 2 | ASTM D1204 |

TD | 0 | (150℃, 30min) | ||

friction coefficient | Static | —— | 0.55 | ASTM D1894 |

Dynamic | 0.55 | |||

haze | % | 3.5 | ASTM D1003 | |

glossiness | % | 120 | ASTM D2457 | |

wetting tension | mN/m | 54 | GB/T 14216 | |

FAQ

Coating products: there is no obvious abnormality before the film is processed, and wrinkling is obvious after the oven is cooled after processing.

1,Cause analysis:

(1) Slitting small rolls and insufficient stress release;

(2) There is a large difference in the ratio of vertical and horizontal shrinkage of the films, leading to the crystallization rate or non-uniform secondary shrinkage after high temperature;

(3) Uneven thickness of the film itself, coating film on the substrate level requirements of higher, coating after completion of the film defects more obvious;

(4) The local deviation of the uneven crystallinity of the film after TDO (horizontal pull) shaping and cooling is large.

2. Preventive Measures:

(1) Adjust the appropriate slitting and rewinding pressure;

(2) Adjust the process parameters so that the fim's vertical and horizontal shrinkage ratio is in an appropriate range;

(3) The production control film surface is smoother and the average deviation is smaller;

(4) Adjust TDO (horizontal pulI) temperature to make crystallization faster and more uniform. Defective film surface printing and aluminum plating

1. Cause analysis:

(1) The non-uniform wetting tension of corona does not meet the requirements;

(2) Oil oil is thrown to the film surface during film drawing production, causing film surface pollution;

(3) Problems occurred in the process of customer processing

2. Preventive Measures:

(1) Adjust the electrode spacing of corona generator to make corona uniform, and increase the power to make the wetting tension meet the customer's demand, greater than 56 Dyne;

(2) The equipment shall be flled with bearing lubricating oil in appropriate amount and promptly clean up the spilled grease;Avoid throwing to the film surface during production operation

(3) Solve this problem through customer analysis in use

After slitting and packing, the paper tube and film roll delamination slip out when the film roll

is transported for a period of time.

1. Cause analysis:

(1) The water content of the paper tube core is not qualified. In a high temperature

environment, the water evaporates and the paper tube core shrinks, leading to a smaller

outer diameter.

(2) The starting speed was too fast, and the tension could not keep up with the pressure,

leading to the loose winding at the beginning.

2. Preventive measures

(1) Incoming material inspection shall strictly check the water content test results, and the

warehouse shall have temperature and humidity control.

(2) The winding speed of the first 100 meters is controlled at 50~80min/m.