Overview

Essential details

Condition:

New

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty of core components:

2 years

Core Components:

PLC

Application:

Bottle

Plastic Processed:

PP, PVC, PET, PE

Place of Origin:

Jiangsu,China

Brand Name:

Reliable

Year:

2023

Voltage:

220V/380V

Dimension(L*W*H):

customized

Hollow part volume:

2000 ml

Clamping Force (kN):

2200

PLC Brand:

Siemens

Screw diameter (mm):

3700 mm

Output (kg/h):

20 kg/h

Automation:

Automatic

Screw Heating Power(kW):

78 kW

Extruder Motor Power(kW):

72 kW

Mold Platen Size(Width)(mm):

3152 mm

Mold Platen Size(Height)(mm):

2150 mm

Air Pressure(MPa):

3 MPa

Air Comsumption(m³/min):

30 m³/min

Die Head Heating Power(kW):

72 kW

Accumulator Capacity(L):

6000 L

Power (kW):

30

Weight (T):

4.5

Key Selling Points:

Easy to Operate

Warranty:

2 years

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory, Food Shop, Food & Beverage Shops

Showroom Location:

Turkey, Italy, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia

Blow Moulding Type:

Extrusion Blow Moulding

Material:

SUS304/316

Capacity:

4000PCS/H

Product name:

Automatic Blowing Molding Machine

Suitable bottle:

PP PE ABS HDPE PVC

Key words:

Blowing Mold Machine

Marketing Type:

Hot Product 2023

Advantages:

Servo Motor Energy Save

Brand:

Reliable

PLC:

Siemens

Supply Ability

Supply Ability

3 Set/Sets per Month Water Bottle Blowing Machine

Packaging & delivery

Packaging Details

The normal packages is wooden box.If enter container the packages is too tight,we may use PE film to wrapping the machine.

for Small Glass Bottle Mango Juice Filling Machine.

Port

Shanghai Port

Picture Example:

Lead time:

Quantity(sets) 1 - 1 2 - 2 >2 Lead time (days) 30 45 To be negotiated

about Reliable Machinery

Zhangjiagang Reliable Machinery Co., Ltd. is one of the most credible and international solution provider which integrates designing, producing, marketing and offering the turn-key project of liquid filling and packing line. based on 15 years of research, experience and advanced technology absorbed from Europe and America, Reliable has become the industry leading manufacture and deeply appreciated by many major brands all over the world.

Product Features

Brief Introduction

RM-4000 type Automatic PET Bottle Blowing / Making Machine is suitable for blowing PET bottles of various shapes, volume from 100 ml to 2000 ml, wide application for blowing mineral water bottles, soda bottles, cola bottles..

1.New double crank four pull-up bar clamping structure, cross balance fixed slide; 2. Sealing, stretch adapts parallel bars (CIS) design, combined, good for products molding; 3. Advanced gas path design, single, dual air intake can be; low-pressure mechanical clamping, sealing, stretching; high pressure blowing molding; 4. Programmable PLC controller automatically control, microcomputer touch screen convenient operation; 5. Bottle embryo heated by infrared, controllable constant pressure control, so as to achieve the best blowing precision.

Selection For Capacity

MORE DETAILS

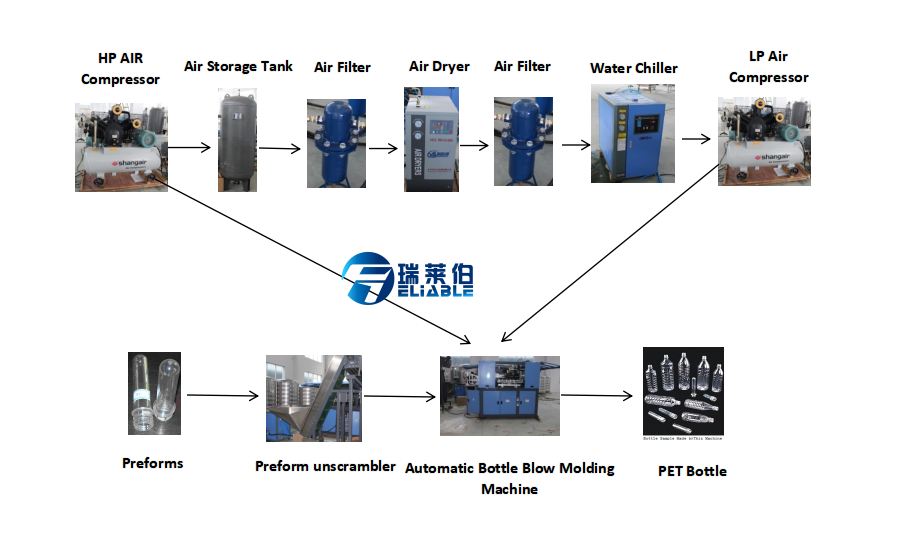

Principle Display

Preform→Preform storing parts→Preform heating(temperature adjustment) →(Pull stretch→Blow air→ Release Air→ Blow pin and mouth at same time→Close the blow mouth→Forming)→Finished

Heater Part

1 - Adopt special electronic controlling circuit for heating, high efficiency in simultaneous controlling. 2 - one lamp or more, lower power consumption. 3 - The preform will be heated evenly, not be influenced by outside environment. 4 - Cooling system with cold air cycle ensures same heat exposure of internal and external surface.

Blower Part

1 - Wide adaptability, suitable for every type mould thickness. 2 - Special design,high rigid compound die structure. 4 - High responsiveness pneumatic components,action timely and precisely. * In this stage, the preheated bottle billet (embryo) is placed into the already prepared blowing mold, and the high pressure inflation is carried out in it to blow the bottle billet (embryo) into the required bottle.

Advantages

1).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

2).High Quanlity:Steady infrared heating system blowing and highly precise blow-mould closing system ensure quality.

3).High Speed:2000BPH,4000BPH,6000BPH...

4).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

5).Low Cost:Low consumption of electricity, air and water.

6).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

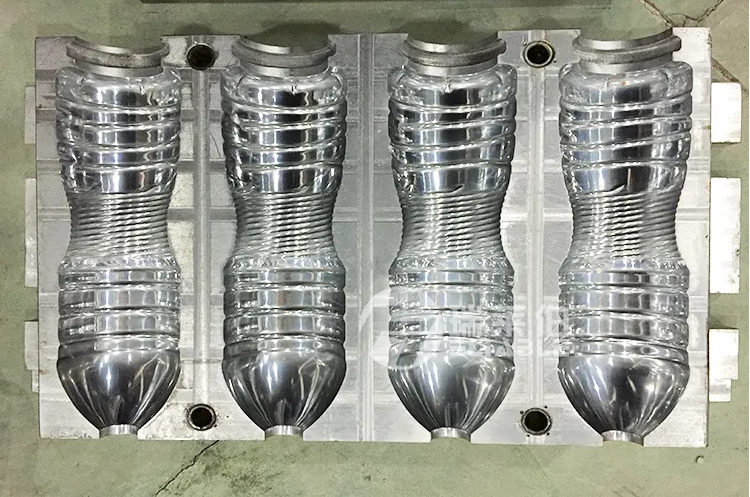

MOULD & BOTTLE SHOW

A variety of bottle shapes can be customized at Reliable Machinery.