Overview

Essential details

Condition:

New

Type:

Filling Machine

Machinery Capacity:

2000BPH

Applicable Industries:

Food & Beverage Factory, Farms, Restaurant, Food Shop, Food & Beverage Shops

Showroom Location:

Egypt, Canada, Turkey, United Kingdom, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia

Application:

Beverage, Chemical

Packaging Type:

Bottles

Packaging Material:

Plastic, Glass

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

220V/50HZ

Place of Origin:

Jiangsu, China

Brand Name:

Reliable

Dimension(L*W*H):

1800*700*1900

Weight:

1800 KG

Warranty:

2 years, 2 years

Key Selling Points:

it is suitable all different pet bottle shapes

Filling Material:

Milk, Water, Oil, Juice

Filling Accuracy:

≤0.1%

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

2 years

Core Components:

Motor, PLC, Engine

Product name:

Bottle Making machine

Function:

bottle making machine

Brand:

Reliable

Bottle Volume:

200ml-2000ml

Packaging & delivery

Selling Units:

Single item

Single package size:

20X30X80 cm

Single gross weight:

20.000 kg

Package Type:

Wooden Carton

Picture Example:

Lead time:

Quantity(sets) 1 - 2 >2 Lead time (days) 15 To be negotiated

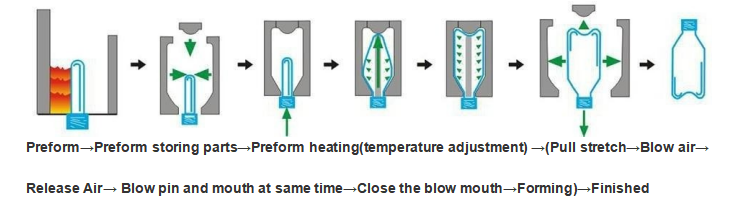

Suitable for all shapes of PET plastic bottles,widely used to produce the carbonated bottle, mineral water, pesticide bottle oil

bottle cosmetics, wide-mouth bottle and hot fill bottle etc

Brand: Reliable Machinery-----Automatic Blowing Machine

Application:0.2-2L

Capacity:2000BPH

Warranty:2 Years

Semi automatic bottle blow molding machine is suitable for producing PET plastic containers and bottles. It is widely used to produce the carbonated bottle ,mineral water,carbonated drink bottle, pesticide bottle oil bottle cosmetics,wide-mouth bottle etc.

Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,the perform

rotated and heated equally.

The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements for the action and blow .It can provide sufficient and steady high pressure for blowing large irregular shaped bottles. Simple installation & start-up adjustment.

Process Flow chart:

Features:

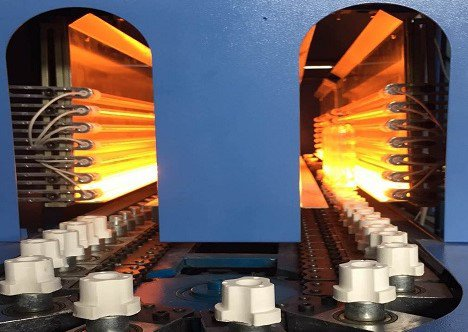

1. The heat penetration is strong and the preform receives even heat with self-rotating during the preheating process.

2. This series of bottle blowing equipment is highly adaptable. By adjusting the distance between the lamp tube and the reflector,

the preform can fully absorb heat. Equipped with an automatic constant temperature device, the temperature can be maintained within a certain range.

3. There is a safety locking device during each mechanical action to protect the operator's safety.

6. Use air cylinder instead of hydraulic cylinder, less pollution and low noise.

7. Use different air pressure for blowing and machine operation, energy saving and environmental protection.

8. Equipped with high pressure and double crank connecting rod clamping to provide high clamping force.

10. Safe, reliable and unique valve position design makes the blowing process easier to control.

11. The blowing machine has the characteristics of low cost, high efficiency, easy operation and maintenance, and advanced

automatic process.

12. Avoid contamination of the bottle.

13. Protection of low temperature cooling system.

14. Easy to install and start.

15. Low scrap rate.

Machine Details:

Using Infrared preform heater. Adopt special electronic controlling circuit for heating, high efficiency in controlling. The preform will be heated evenly, not be influenced by outside environment. Cooling system with cold air cycle ensures same heat exposure of internal and external surface. Heating lamps are adjustable in directions to suit various preforms.

Short mould stroke,quick action. Wide adaptability, suitable for every type mould thickness. Special design,high rigid compound die structure.High responsiveness pneumatic components,action timely and precisely.

Short mould stroke,quick action. Wide adaptability, suitable for every type mould thickness. Special design,high rigid compound die structure.High responsiveness pneumatic components,action timely and precisely.

Short mould stroke,quick action. Wide adaptability, suitable for every type mould thickness. Special design,high rigid compound die structure.High responsiveness pneumatic components,action timely and precisely.