Overview

Essential details

Condition:

New

Type:

Filling Machine

Machinery Capacity:

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

Applicable Industries:

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory

Showroom Location:

Egypt, Turkey, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Japan, Australia

Application:

Food, Beverage, Machinery & Hardware

Packaging Type:

Cartons, CANS, Bottles, Barrel

Packaging Material:

Plastic, Paper, metal, Glass, Wood

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

Adjustable

Place of Origin:

Jiangsu, China

Brand Name:

Reliable

Dimension(L*W*H):

2900*2100*2400mm

Weight:

3500 KG

Warranty:

2 years, 2 years for machine, 2 year for spare parts

Key Selling Points:

High-accuracy

Filling Material:

Milk, Water, Juice

Filling Accuracy:

100

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

2 years

Core Components:

Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

After-sales Service Provided:

Engineers available to service machinery overseas

Product name:

Juice Beverage Filling Line

Filling material:

juice

Bottle Type:

PET Bottle

Function:

filling and package

Bottle Size:

0.2-2L

Material:

SUS304/316

Operation:

Easy&Stable

Capacity:

8000bph for filling machine

Supply Ability

Supply Ability

16 Set/Sets per Month Complete Line Drinking Juice Making Machine Filling And Package

Packaging & delivery

Packaging Details

Complete Line Drinking Juice Making Machine Filling And Package Line

PE Film

Wooden Box

Port

shanghai port

Picture Example:

Lead time:

Quantity(sets) 1 - 1 2 - 2 >2 Lead time (days) 30 45 To be negotiated

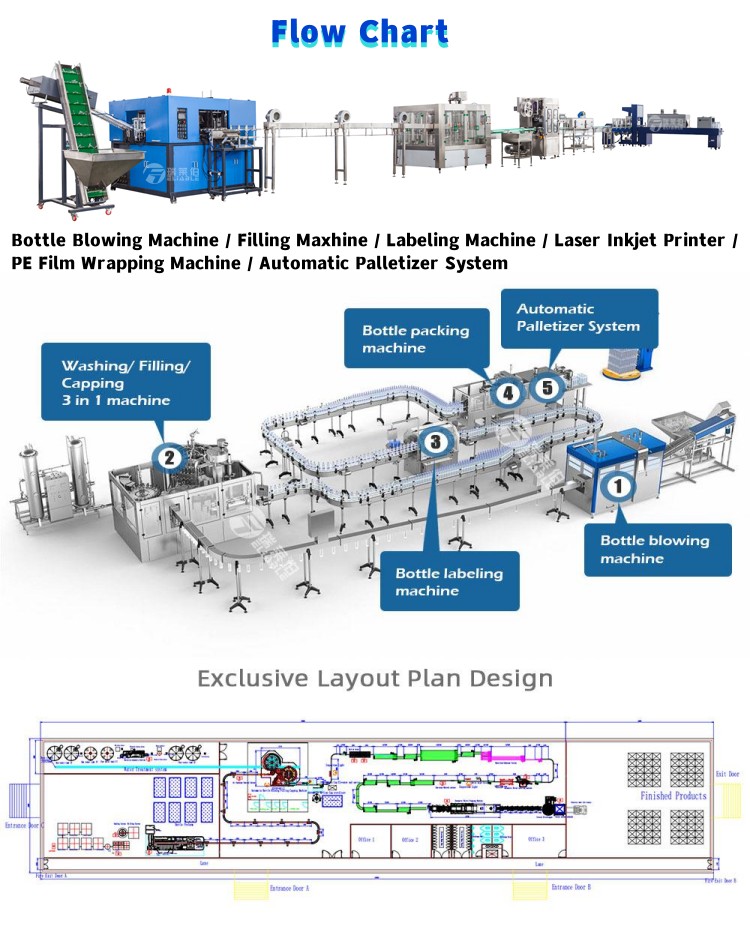

Whole Production Line

Brief Introduction

Automatic triad filling machine, suitable for fruit juice, vegetable juice ,tea drink production line, the whole machine adopts the health level of SUS304 stainless steel materials, Japan's mitsubishi PLC control, Taiwan nylon touch screen, is convenient to operate, the advantages of easy to maintain, yield range 2000-24000 bottles/when the whole line compatibility is strong, can adapt to all kinds of bottle shape just change a few parts.

Model Options

Features of Hot Filling

The hot filling is relative to the traditional beverage processing technology. For non-carbonated beverages, the traditional production process is to fill the preheated or cold product into the bottle (can). The formula is performed by Basal sterilization or high-temperature sterilization, and then cooled and dry to make products. The hot filling first performs a UHT sterilization of the product. Infiltration is performed at the temperature of 80°C to 95°C. After the cover, the inner wall and bottle cap of the packaging container are used to sterilize the inner wall and bottle cap of the product itself. The hot filling process has an efficient and energy-saving effect, because all the operation of the thermal irrigation process is completed on the assembly line, which can effectively improve production efficiency, reduce energy consumption and manual operations, and the thermal irrigation process can preserve product flavor and nutrition to the maximum extent. The ingredients, because the thermal irrigation drink must be carried out with UHT sterilization, and the heating and cooling must be very rapid. There is no secondary sterilization after sealing. The second sterilization has also reduced the bottle break and jump cover in this process.

Condition:thick and hard PET bottle

Detailed Process

Bottle Blowing Machine

PET Bottle Blowing / Making Machine is suitable for blowing PET bottles of various shapes, volume from 100 ml to 2000 ml, wide application for blowing mineral water bottles, soda bottles, cola bottles.

Option: Semi automatic and Full automatic models

Water Treatment System

It can effectively get rid of muddy organic, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of micro-organism and some of height-metal ion in the water. This water treatment equipment can also reduce hardness of water to make it all specifications of the water quality fully meet the state fresh water standards, even that of standard of mineral water.

Mixing Beverage Machine

Reliable beverage mixing machine is to improve the proportion of water, syrup and carbon dioxide precise and elaborate design. It is suitable for the mixing of various types of drinks. Such as soft drinks, fruit drinks, cola and other hard drinks.

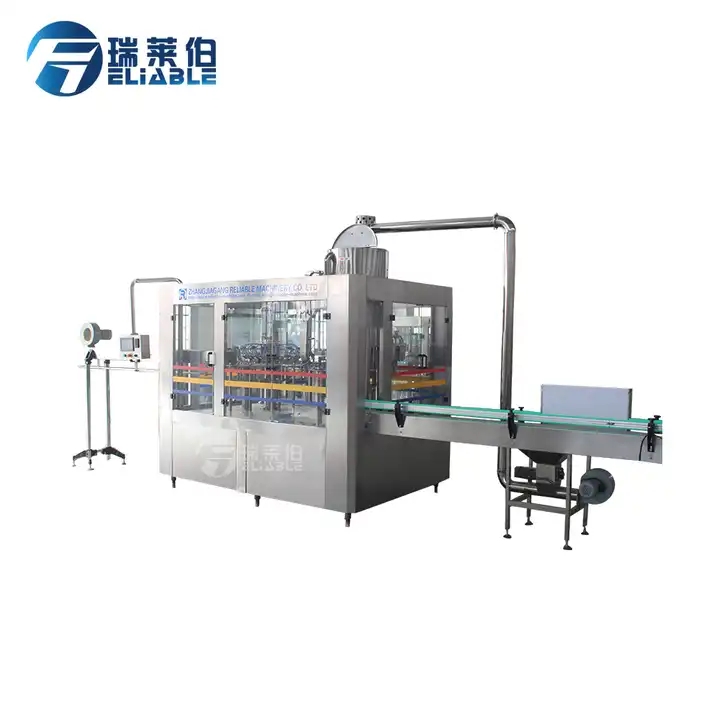

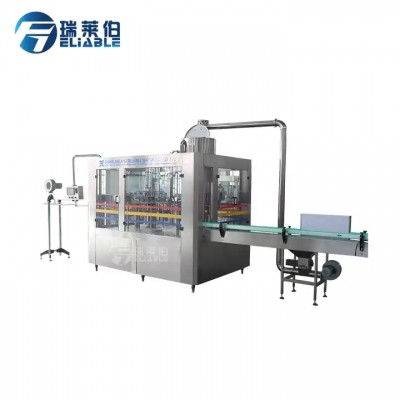

Bottle Washing-Filling-Capping Machine

This three-in-one machine for PET bottle integrates the functions of rinsing, filling and capping together.

Option: 2000BPH / 4000BPH / 8000BPH / 12000BPH / 15000BPH / 20000BPH / 24000BPH

Labeling Machine

This shrink sleeve labeling machine adopts international advanced technology to coverthe circle label on the PET bottle.And then , hot shrinking to fix on the position which bottlebody designated.

Option: PVC sleevelabel, self-adhesive label, OPP/BOPP label and so on.

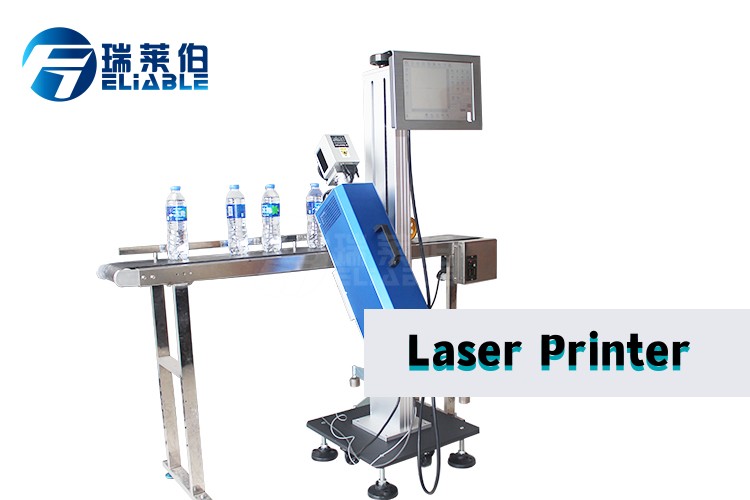

Code / Date / Batch Printer

Printing production date in bottle.

Option: Inkjet type, laser type