Overview

Product Description

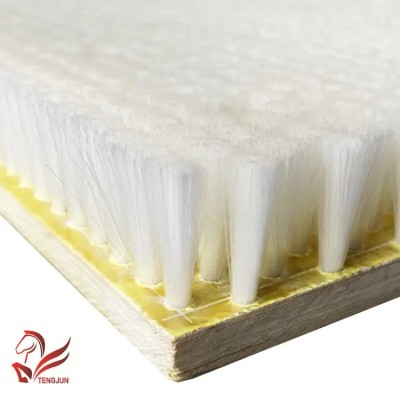

In order to save costs and reduce machine footprint, customers can choose our light finisher and drying machine. there is a spacer layer between the adhesive and the baking plate to prevent ozone damage to the machine.

Machine Benefits

Function 1:the process of light finisher and post-exposure is accomplished by using UVC and UVA light sources, which can remove stickiness on flexo plates, improve clarity and lenthen service life of flexo plateFunction 2: drying flexible plate by preheated drying drawerPerformance:1.Drawer type light finisher layer and drying layer, UVA and UVC mixed light source for light finisher layer 2.built-in effective air exhaust device to effectively discharge ozone 3.the big size machine, can control lamp tube partition , the top cover of machine can be opened. Each lamp tube has an indicator lamp, which facilitates the replacement of the lamp tube. 4.each section temperature control, can be adjusted of independently, different thickness of plate can be managed separately 5.Drawers are insulated of reduce heat loss and minimize energy consumption. 6.Drawers are equipped with air intake grooves and built-in high-strength fan, to allow real air circulation ,fast heat transfer and uniform temperature regulation,Max Supports Plate Sizes : 2030x1320mm(52x118inch)

Each tube has an indicator light

Reasonable Circuit Arrangement

Ozone exhaust connector

Built in exhaust ozone pipe

built-in high-strength fan, make air circulation

UVA and UVC cross arrangement fast heat transfer and uniform

each section temperature control independent

equipped air intake grooves ,make heat alive

Specification

Company Profile

Guangzhou tengjun flexo co.ltd was established in 2017,its a new company but quite experienced in flexographic plate and plate making machine manufacturing. we have been committed to research& develop flexographic plate making machine over a decade. Additionally, we independently create suspended crankshaft swing design of In-line washing machine. based on experience& customer feedback and marketing demands. it greatly solves the requiries as high-precision dots and high-definition lines. Our flexible plate making machine is suitable for: flexible packaging printing (cigarette packaging and medical packaging, etc.), corrugated paper printing, carton printing, label/tag printing, screen printing, etc. At present, the feedback from domestic customers are quite good ---runs smoothly and functionally. we now try to promote our flexographic plate making machine overseas to expand market and help more clients solve issues of their current machines worldwidely share qualified machines with the world.

Company Basic information Company name : Guangzhou tengjun flexo co.ltd Year Established:2017 Business Type: Manufacturer,Trading Company Main Products:Flexographic Solid Plate Making Machine and Solvent Recovery Machine Company Location: Office ADD:2/F,NO.51, NO.3 INDUSTRY TOWN,HUADUDISTRICT,GUANGZHOU 510840 Factory ADD:NO.10 RonGLIN RODAY BAIYUN DISTRICT,GUANGZHOU CITY Office size : about 2000 square meter