Application:

Liquid: detergent, fruit juice, miller wine, soy sauce, vinegar, drinks, etc.

Thick Liquid: chilli sauce, ketchup, peanut butter, jam, bean sauce, etc.

Specifications:

| Specification for MR8-200CY Liquid Packaging Production Line | |

| Model | MR8-200CY |

| Working Positions | Eight Positions |

| Pouch Type | Four-side Sealed Bags, stand-up pouches, zipper bags, three-side sealed bags, paper bags, etc. |

| Capacity | 20-40 bags/min(speed may vary with product charcateristics, pouch or other operation condition) |

| Bag Size | Width:80~210mm Length:100~300mm |

| Filling Volume | 10-1500g(Depend on type of products) |

| Package Error | ≤±1 |

| Dimension | 1450*1560*1525mm(L*W*H) |

| Weight | 1450KGS |

| Compress air requirement | ≥0.8m³/min supply by user |

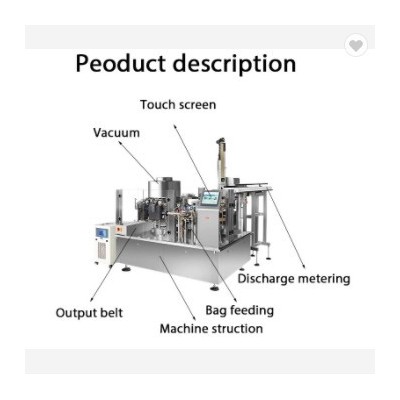

Features and Characteristics:

1. The Liquid, paste packaging system consists of a rotary packing machine and a liquid or paste filling machine

2. A perfect quality ensures a speedy and stable production

3. High quality accessories make machines durable and stable

4. Waterproof system makes cleaning easier. Color touch screen display, easy to operate

5. The machine and the other devices make up a packaging system

6. Provide an innovative and practical solution at reasonable costs

7. A low material waste. The machine adopts premade perfect-pattern pouch, with high-quality sealing

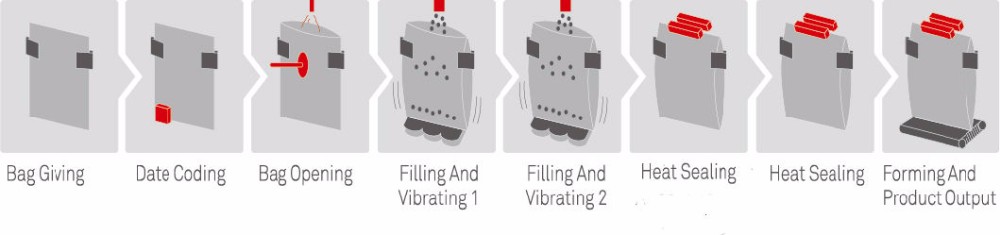

Work process:

bag giving→date coding →bag opening →filling and vibrating 1→filling and vibrating2→heat sealing 1→heat sealing 2→forming and output

Pouch Type:

Standard Equipment Part:

| 1. Date printer | 6. Magnetic valve |

| 2. PLC control system | 7. Temperature controller |

| 3. Pouch opening devices | 8. Vacuum pump |

| 4. Vibrator device | 9. Frequency convertor |

| 5. Cylinder | 10. Output system |

Optional Configuration:

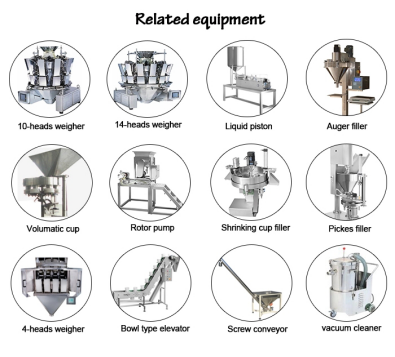

Material weighing filling machines, work platform, weight checker, material elevator, finished product conveyor, metal detector

learn more learn more learn more

verified

verified